A

LPHA

X

PRESS

2020 RGB F

RONT

A

CCESS

F

ULL

-M

ATRIX

D

ISPLAYS

S

IGN

O

PERATION

AND

M

AINTENANCE

M

ANUAL

(PN 1523610201

REV

.

B

)

1-3

Introduction

1

S

YSTEM

OVERVIEW

VMS control system

The VMS control system used in the Variable Message Sign consists of the following components:

•

NTCIP compliant controller

•

LED display board/driver board

•

Sign controller

•

Display adapter

General operation

The NTCIP controller interfaces with the “Host” computer system, and communicates with the Host through a CAT5 Ethernet cable

(standard) or an RS422 connection (option). Using this network connection or I/O port, the Host issues commands to, and requests

status information from, the NTCIP controller. The controller monitors and controls the entire LED VMS system. Communication by the

NTCIP controller to and from the Host is accomplished using industry standard 10/100 Ethernet communications circuitry and NTCIP

protocol.

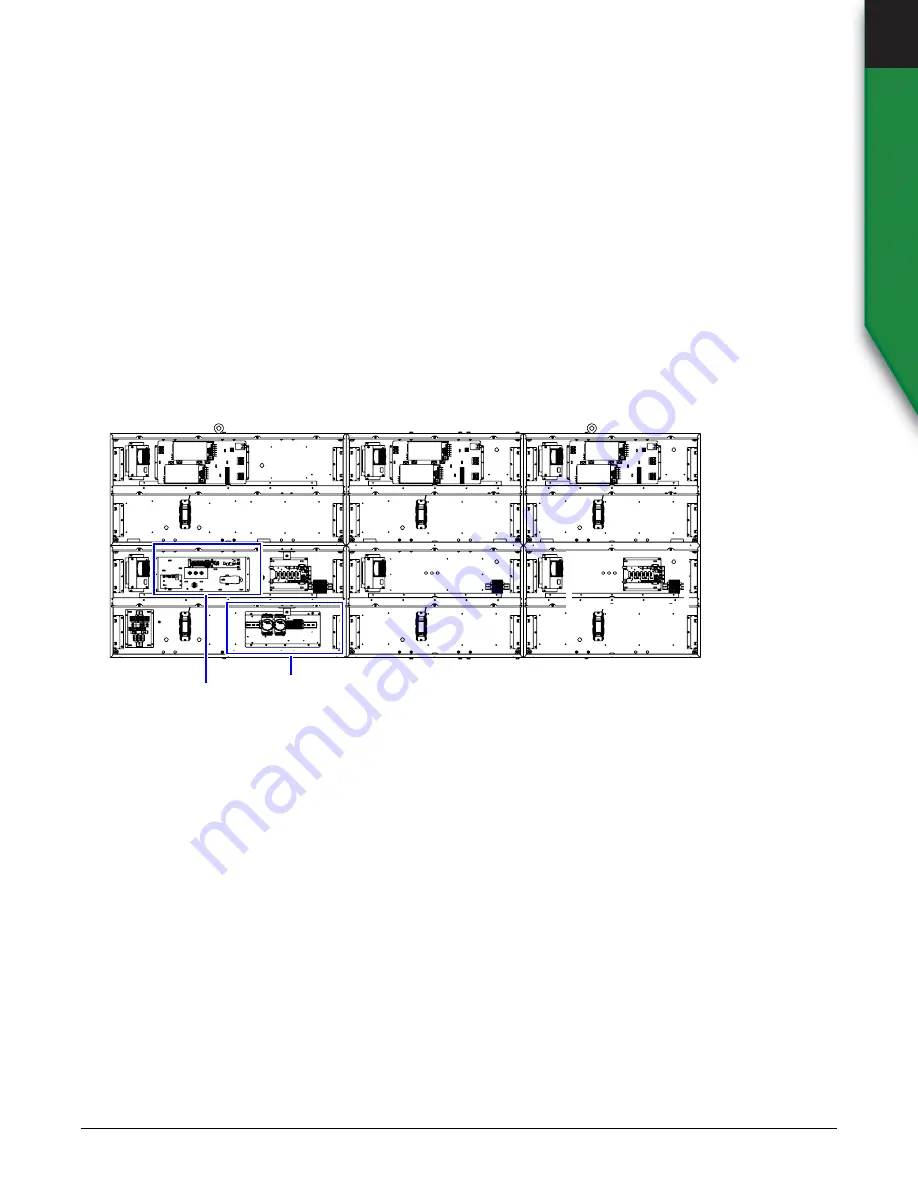

Placement of controllers

The controllers are located in the lower left modular case of all AlphaXpress 2020 sign configurations. Single row signs have a remote

mounted controller.

LED brightness control system

The VMS is equipped with a brightness control system for the LEDs. The brightness control system ensures that the display is readable

in all lighting conditions. The photocells are enclosed to protect them from the environment. Three photocells continually monitor the

ambient light conditions. The photocell assembly is constructed in such a manner that adverse weather conditions (such as heavy

snow) should have no effect on its performance. The main components of the brightness control system are the following:

•

Sign Controller

•

Light

sensor

assembly

General operation

The photocells are enclosed in an assembly designed to protect them from the environment. The photocells continuously monitor the

ambient light conditions and the controller constantly polls the photocells for this information. The controller determines exactly how

much ambient light is detected through the light-sensing photocells and sets the light output of the display module for it to adjust duty

cycle of the LED current drive, thus dimming or brightening the LED modules according to the ambient light. (If the on time of the duty

cycle is 50%, then the light output will be at 50%; if the on time of the duty cycle is 75%, then the light output will be at 75%, and so on.)

Light sensor assembly mounting

Because the function of the photocells depends on ambient lighting, the light sensor assembly should be mounted in a location where

it will receive maximum light exposure throughout the day. When choosing a mounting location for the light sensor assembly, make

sure the assembly can receive ambient light on the front.

I/O plate

Sign controller plate

Summary of Contents for AlphaXpress 2020

Page 51: ......