VUE

23

I – 3 T

u

rn

ing Specific Oper

ations

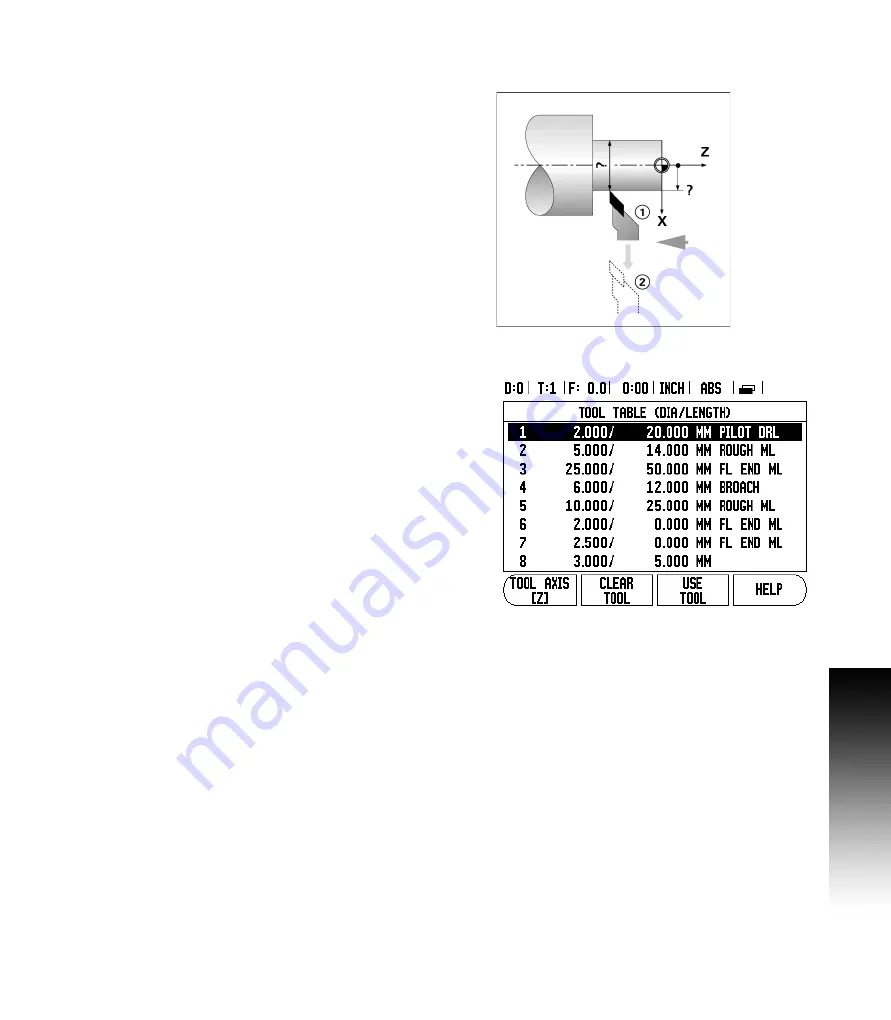

Setting Tool Offsets with Lock Axis Function

Example 2: LOCK AXIS

The LOCK AXIS function can be used to set a tool’s offset when a tool

is under load, and the diameter of the workpiece is not known.

The LOCK AXIS function is useful when determining tool data by

touching the workpiece. To avoid losing the position value when the

tool is retracted to measure the workpiece, this value can be stored by

pressing LOCK AXIS.

To use the LOCK AXIS function:

U

Press the TOOL hard key.

U

Select tool, and press ENTER.

U

Press the X axis key.

U

Turn a diameter in the X axis.

U

Press the LOCK AXIS soft key while the tool is still cutting.

U

Retract from the current position.

U

Turn the spindle off, and measure the workpiece diameter.

U

Enter the measured diameter, or radius, and press ENTER.

Remember to ensure the VUE is in diameter display mode (Ø).

Calling a Tool from the Tool Table

U

To call a tool, press the TOOL hard key.

U

Use the UP/DOWN arrow keys to Cursor through the selection of

tools (1-16). Highlight the tool wanted.

U

Verify the proper tool has been called, and press either the use the

TOOL soft key, or the C key to exit.

Summary of Contents for VUE

Page 2: ......

Page 6: ...vi Readout Parameter Access Code ...

Page 8: ...viii VUE Fonts ...

Page 10: ...x ...

Page 14: ...xiv ...

Page 54: ...40 II 3 Dimensions ...

Page 57: ......