T-ABVA Manual |Rev.C, JULY 2017 Page 2

General Description

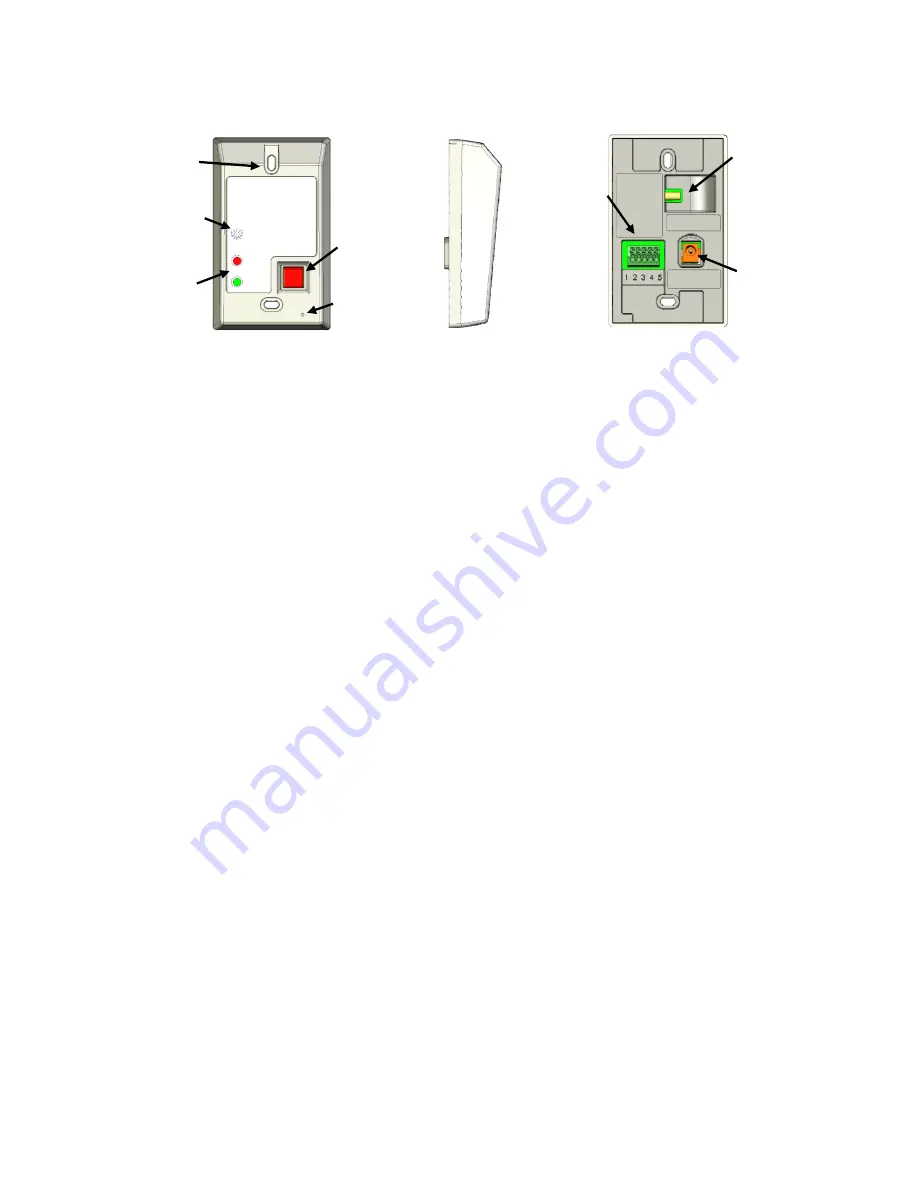

1. Mounting Holes:

Both mounting holes are elongated to provide horizontal and vertical adjustment so

the alarm can be perfectly aligned with the mounting surface.

2. Inlet Port:

Air is drawn in from the room through the inlet port where it is measured by the internal

mass flow sensor and then exits into the negatively pressurized fume hood or BSC exhaust duct.

3. Visual Status Indicators:

There are two visual status indicators; one Red LED and one Green LED.

During normal operation, the Green LED is ON and the RED LED is OFF. During an alarm condition,

the Green LED is OFF and the RED LED Flashes. When the Mute Button is pressed and held for 3-

seconds, the two LEDs are also used to indicate which calibration mode is presently active.

4. Mute Button:

Highly visible and easy to access for quick actuation.

Pressing the Mute Button momentarily

during an alarm condition will silence the horn. Pressing

Mute again, will reactivate the horn. If the horn is muted and the alarm has not cleared, the horn will

chirp (re-beep) every five minutes as a reminder that the horn is muted.

Pressing and holding the Mute Button for 3-seconds

, will provide a visual indication of the present

calibration mode. If one LED turns ON, then the unit is operating in Mode 1. If both LEDs turn ON,

then the unit is operating in Mode 2.

Pressing and holding the Mute Button for 15-seconds,

will disable the horn with no re-beep. The

horn will remain OFF until the Mute Button is pressed again or the alarm condition clears.

5. Calibration Button:

The calibration button is recessed to prevent accidental triggering. To press the

calibration button, use the end of a paper clip.

Pressing the Calibration Button momentarily

will toggle the alarm calibration mode.

Pressing and holding the Calibration Button for 5-seconds

, will initiate the Alarm Calibration.

Pressing and holding the Calibration Button for 10-seconds

, will re-zero the sensor. The sensor

should not need to be re-zeroed unless directed to do so by the factory. Re-zero should only be

performed with the airflow sensor blocked.

6. Tilted Surface:

Because the alarm is normally installed above eye level, the front surface is angled

downward for easy viewing.

7. I/O Terminal Block:

Use stranded wire between 16 and 20 AWG only, stripped back ¼ - ½ inch.

Remote Mute:

Sending a contact closure to the Remote Mute input will mute the horn same as

pressing the Mute Button. Remote Mute is normally used during unoccupied hours.

Alarm Output:

Alarms can be communicated to other devices and the building automation system

using the relay output at terminals 3, 4 and 5. The relay changes state during alarm condition, and

returns to normal when the alarm condition has been cleared.

8. Hood Probe Port:

This is the exit side of the mass airflow sensor. Tubing from the hood probe or

BSC exhaust duct is connected here.

9. Input Power Plug:

The DC Power Module provided connects directly to plug on the back of the unit.

1. Mounting

Holes

6. Tilted

Surface

2. Inlet Port

3. Visual

Status

Indicators

4. Mute

Button

5. Calibration

Button

8. Hood

Probe

7. I/O

Term.

9. Power

Term.

Front View

Side View

Back View