M 0494 -

14

I

E

a

b

h

GB

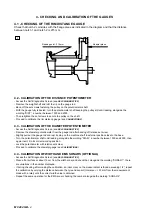

11 - WHEEL MEASUREMENT AND PRESETTING ON THE BALANCING MACHINE

The ever increasing need for more accurate calibration and use of the ALU functions means that it is important to esta-

blish how to measure the rims and how the balancing machine interprets the preset data. Hence a description is now

given of how to modify the preset dimensions automatically in order to obtain the distances of the correction planes

which are defined as through planes for the centres of gravity of the corrective weights.

Consider a typical rim: size “

l

” , given as width by the rim manufacturer, differs from the measurement of the distance

between the correction planes for the rim thickness and physical dimensions of the counterweight, whose centre of

gravity is located at distance “h” from the resting point of the rim edge.

The balancing machine automatically corrects the measurement preset by adding 2 x h = 6 mm to the measurement.

Measurement “b” made with the gauge is generally more accurate even if very similar to the measurement “

l

” known to

the rim user. The two measurements differ only by the thickness of the sheet metal, usually about 2 mm per side. Such

insignificant distance means that an accurate calibration can be obtained regardless of whether the inner rim with “

l

”

or outer width “b” is preset. It is a good rule to add ¼ inch to the value given by the manufacturer. As regards the ALU

functions, the machine performs the following approximations in addition to the systematic correction regarding the

centre of gravity of the counterweight as seen above.

N.B.:

I = INSIDE

E = OUTSIDE

a = a preset - 8 mm

b = b preset - 11 mm

dI = d preset

dE = dI

a = a preset - 3 mm

b = b preset - 16 mm

dI = d preset

dE = dI - 1”

a = a preset - 8 mm

b = b 11 mm

dI = d preset

dE = dI + 1”

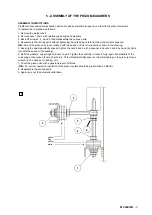

ALUM

a = aI preset - 8 mm

b = aE - aI

dI = dI preset

dE = dI - 1”

ALUM VARIANT

a = aI preset - 3 mm

b = (aE - aI) - 5 mm

dI = dI preset

dE = dI - 2"

0 gauge

(First notch)

0 gauge

(First notch)

Summary of Contents for 1250

Page 1: ...SERVICE MANUAL MODELS 1250 1450 1550 1650 1850...

Page 2: ......

Page 3: ...Model 1250 Wheel Balancer...

Page 5: ...M 0495 2 GB...

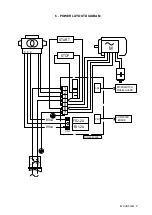

Page 9: ...M 0495 6 3 GB 5 POWER SUPPLY LAYOUT DIAGRAM 230 V connection...

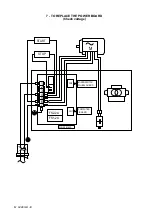

Page 10: ...M 0495 7 4 GB 6 REPLACING THE POWER BOARD check voltage...

Page 14: ......

Page 15: ...Model 1450 Wheel Balancer...

Page 17: ...M 0492 2 GB...

Page 30: ......

Page 31: ...Model 1550 Wheel Balancer...

Page 33: ...M 0493 2 GB...

Page 40: ...M 0493 9 5 GB 6 POWER SUPPLY LAYOUT DIAGRAM...

Page 41: ...M 0493 10 6 GB 7 TO REPLACE POWER BOARD...

Page 46: ......

Page 47: ...Model 1650 Vibration Control Diagnostic System...

Page 49: ...M 0494 2 GB...

Page 55: ...M 0494 8 5 GB 7 POWER SUPPLY LAYOUT DIAGRAM...

Page 56: ...M 0494 9 6 GB 8 TO REPLACE POWER BOARD...

Page 62: ......

Page 63: ...Model 1850 Wheel Balancer...

Page 65: ...M 0496 GB 2...

Page 76: ...SERVICE MANUAL MODELS 1250 1450 1550 1650 1850...