Ap1400 Installers’ Guide Page 13 of 16

12 PAPER

Pressing the paper feed button when the printer is idle, or in spool mode, advances paper at typically

60 mm per second. However, the feed button has additional functions:

"Double-clicking" the button:

(i.e. pressing and releasing twice in quick succession just like a PC mouse)

in idle mode, prints a demo/test message including the firmware version, encoded

calibration data, and the full character set;

in spool mode, or having been out of paper, prints any stored data and enters idle mode.

Some of the functions of the paper feed button can be invoked or disabled under control of the host.

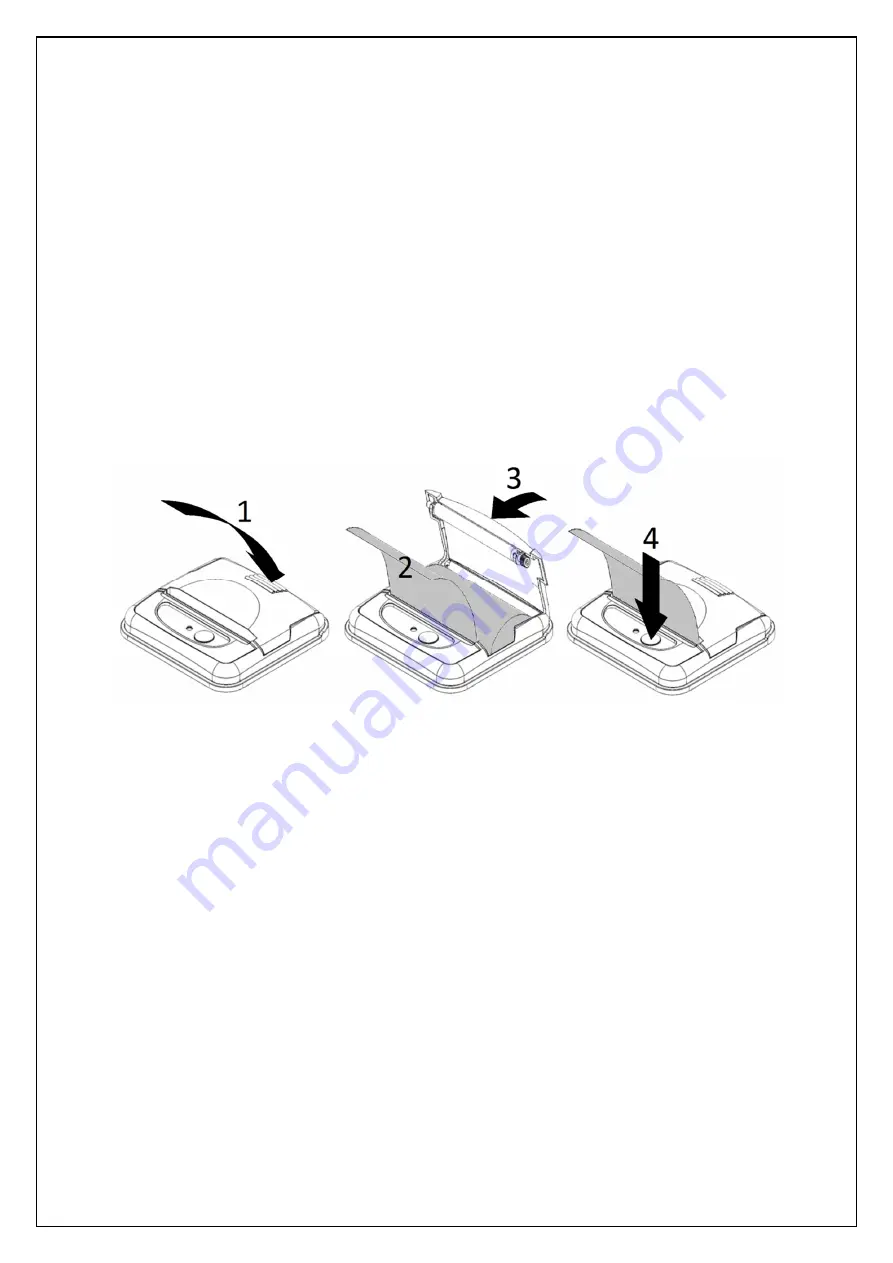

12.1 LOADING PAPER

The procedure for loading paper is as follows:

1. Press the lid in towards the panel.

2. Unwind a small amount of paper from the roll and Insert the Paper Roll into the Printer.

3. Close the Lid, and the paper is loaded.

4. After loading, check that the paper is straight and advances properly, and tear off any excess

by pulling the paper sharply towards you across the serrated tear bar. In the event of a jam or

other paper loading problem, release the lid and straighten the paper before closing again.

Paper rolls must be 57.5 ± 0.5 mm wide, 36 mm maximum diameter, and have the thermally sensitive

coating on the outside. The printer can accept rolls which are coreless or wound on a core. Suitable

rolls are available as ASL Product Code:

A05836TPR1 Thermal Paper Roll (36 mm dia, 13.5 m long approx)

12.2 PAPER OUT AND HEAD UP SENSORS

A reflective optical Paper Out sensor within the mechanism detects an out-of-paper condition, and/or

senses black marks to register with pre-printed forms. A mechanical Head Up sensor detects when

the lid is open.

By default, the printer enters Spool mode automatically if either sensor becomes active. The printer

will automatically exit spool mode, and print any stored data, when new paper is loaded and the lid

closed. This behaviour may be modified. Please refer to the Programmers’ Guide for details of how to

configure these functions.