70

Before the charging procedure

During the charging procedure

After the charging procedure

1

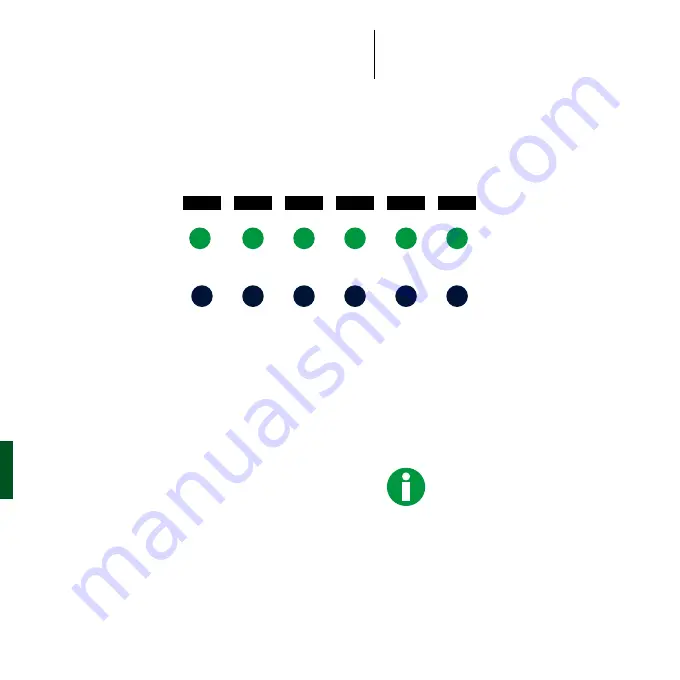

Check that the LED indicators

of the Wallbox display this

operating state. The charging

procedure will start automati-

cally as soon as the vehicle has

been recognised

2

p. 71

3

p. 72

The charging procedure will only

start when

•

the vehicle has been connected

•

the vehicle's charging timer is

activated

The green LED is continuously On

The blue LED is continuously Off

Sequence B1

The Wallbox is waiting for the vehicle to initiate the charging procedure

1sec

1sec

1sec

1sec

1sec

1sec

13. CHARGING

Summary of Contents for 1W1108

Page 1: ...Wallbox eMH1 Installation manual and charging procedure EN 0301800_a...

Page 2: ...2...

Page 3: ...3 English 4 LANGUAGES FURTHER LANGUAGES www abl de Service Downloads...

Page 6: ...6...

Page 7: ...7 1 Safety and user information 8 SAFETY FIRST...

Page 16: ...16...

Page 17: ...17 2 Your model variant 18 3 Components included 20 4 Accessories 21 INTRODUCTION...

Page 58: ...58 12 START UP LED operating states On On Flashing Flashing Off Off...

Page 62: ...62...

Page 78: ...78...

Page 85: ...85 15 TECHNICAL SPECIFICATIONS 221 mm 116 mm 272 mm...

Page 93: ...93...