EN - 14

BAL.0523.0 • 2019-10-17

6 Commissioning

iSTM mini

In order to determine the optimum position of the wire feeder at extreme welding positions, we recommend the following axis

positions:

A6 >

±

100°, A5 >

±

90°, A4 >

±

100°

This procedure avoids extreme stress on the cable assembly.

1

Loosen the wire feeder

2

in the specified direction.

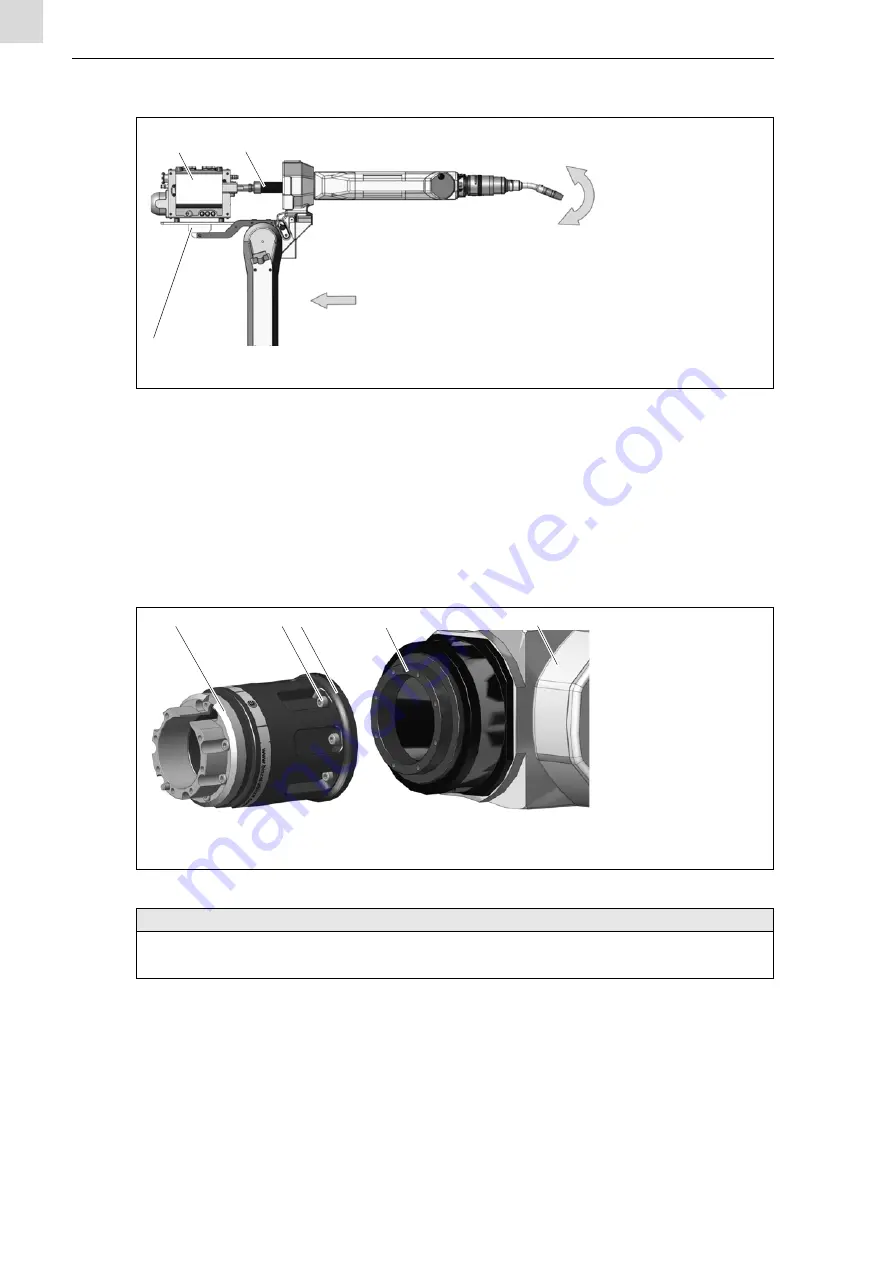

6.2.1 Attaching the iSTM mini to the robot

Mount the iSTM mini

with eight cylinder head screws M4 × 12

and a max. tightening torque of M = 4 Nm on the

welding robot

.

The pin hole

in the welding robot

serves as a reference point between the iSTM mini

and welding robot

.

1

Wire feeder

2

Cable assembly

3

Wire feeder mount

Fig. 9

Standard axis positions

Mounting direction of the cable assembly

1

3

2

J5

(A5)

−90

1

iSTM mini

2

Cylinder head screws M4 × 12 (8

pieces)

3

Intermediate flange for iSTM mini

4

Pin hole

5

Welding robot

Fig. 10

Attaching the

iSTM mini

to the robot

NOTICE

• The type of intermediate flange

used for the iSTM mini

model. The number

and size of cylinder head screws

used also depend on the welding robot.

1

2 3

5

4