34

4.4.3

Opening procedure

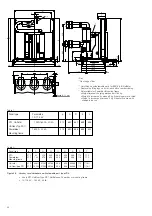

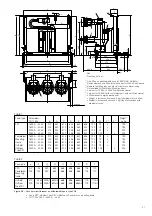

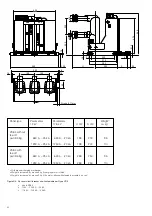

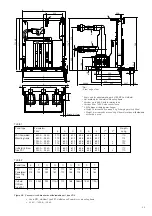

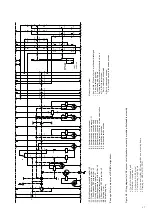

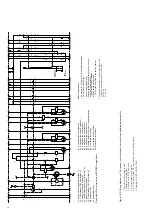

(Figures 4/4, 4/6 and 4/7)

The opening procedure is initiated by mechanical OFF

push-button 12 or by activation of one of releases -Y2,

-Y4, -Y7 or -Y9. Observe the notes in section 4.3.1 on

control of the releases. Release mechanism 31 then

permits drive shaft 30 to be turned further by the spring

energy storage mechanism, which is still sufficiently

charged. Opening spring 27, which is thus released,

moves contact 20.3 into the open position at a defined

speed.

4.4.4

Auto-reclosing sequence

An OFF-ON or OFF-ON-OFF auto-reclosing sequen-

ce is activated and checked by the protection

system. It is necessary for the spiral spring in the

operating mechanism to be in the (re-)charged

condition, with the circuit-breaker in the closed

position. The (re-)charging process is carried out

automatically after closing of the breaker on

breakers with motor charging mechanisms, but

must be carried out manually on breakers without

charging motors (or when the charging motor has

broken down). Opening of the breaker is also

possible during the (re-)charging process, but sub-

sequent closing of the breaker is however blocked

until the charging process has been completed.

4.4.5

Quenching principle of the vacuum interrupter

Due to the extremely low static interrupter cham-

ber pressure of 10

-4

to 10

-8

mbar, only a relatively

small contact gap is required to achieve a high

dielectric strength. The arc is extinguished on one

of the first natural current zeros.

Due to the small contact gap and the high

conductivity of the metal vapour plasma, the arc

drop voltage, and additionally, due to the short

arcing time, the associated arc energy, are extre-

mely low, which has advantageous effects on

the life of the contacts and thus on that of the

vacuum interrupters.

4.5

Interlocks/protection against maloperation

for the withdrawable circuit-breaker part

A series of interlocks are provided to prevent

dangerous situations and any maloperation. The

interlocks of the panel system ZS and/or the

mounting frame, which are normally effective, are

as follows (concerning the circuit-breaker):

• The withdrawable part can only be moved from

the test/disconnected position into the service

position (and back) with the circuit-breaker open

and the earthing switch open (that means that

the breaker must opened before)

• The circuit-breaker can only be closed when the

withdrawable part is precisely in the defined test

position or service position (mechanical inter-

lock, with additional electrical interlock for

circuit-breakers with electrical releases).

• The circuit-breaker can only be opened

manually in the service or test position when no

control voltage is applied, and cannot be closed

(electromechanical interlock).

• Connection and disconnection of the control

wiring plug connector (8.1) is only in the test/

disconnected position possible.

• The earthing switch can only be closed when the

withdrawable part is in the test/disconnected

position or the removed position (mechanical

interlock).

• The withdrawable part cannot be moved from

the test/disconnected position into the service

position when the earthing switch is closed

(mechanical interlock).

• Details of any additional interlocks, e.g. in

connection with a blocking magnet on the

withdrawable part and/or earthing switch

operating mechanism, can be found in the order

documents for each individual case (see also

section 8.5.6).