20 CI/FSV/FSS/430/450-EN Rev. G |

VortexMaster FSV430, FSV450 SwirlMaster FSS430, FSS450

5

Installation

DANGER

Danger of explosion if the device is operated with the

transmitter housing or terminal box open!

Before opening the transmitter housing or the terminal box,

note the following points:

— Check that a valid fire permit is available.

— Make sure that there is no explosion hazard.

— Switch off the power supply before opening and observe

a waiting time of t > 20 minutes.

5.1

Installation conditions

5.1.1

General information

A Vortex or Swirl flowmeter can be installed at any point in the

pipeline system. However, the following installation conditions

must be considered:

— Compliance with the ambient conditions

— Compliance with the recommended inlet and outlet

sections.

— The flow direction must correspond to that indicated by

the arrow on the sensor

— Compliance with the required minimum interval for

removing the transmitter and replacing the sensor

— Avoidance of mechanical vibrations of the piping (by fitting

supports if necessary)

— The inside diameter of the sensor and the piping must be

identical

— Avoidance of pressure oscillations in long piping systems

at zero flow by fitting gates at intervals

— Attenuation of alternating (pulsating) flow during piston

pump or compressor conveying by using appropriate

damping devices. The residual pulse must not exceed

10 %. The frequency of the conveying equipment must not

be within the range of the measuring frequency of the

flowmeter.

— Valves / gates should normally be arranged in the flow

direction downstream of the flowmeter (typically: 3 x DN).

If the measuring medium is conveyed through piston /

plunger pumps or compressors (pressures for fluids >

10 bar / 145 psi), it may be subject to hydraulic vibration

in the piping when the valve is closed. If this does occur,

the valve absolutely has to be installed in the flow direction

upstream of the flowmeter. Suitable damping devices (e.g.

air vessels) might need to be fitted.

— When fluids are measured, the sensor must always be

filled with measuring medium and must not run dry.

— When fluids are measured and during damping, there

must be no evidence of cavitation.

— The relationship between the measuring medium and the

ambient temperature must be taken into consideration

(see data sheet).

— At high measuring medium temperatures > 150 °C

(> 302 °F), the sensor must be installed so that the

transmitter or terminal box is pointing to the side or

downward.

5.1.2

Inlet and outlet sections

SwirlMaster FSS430, FSS450

On account of its operating principle, the swirl flowmeter

functions virtually without inlet and outlet sections.

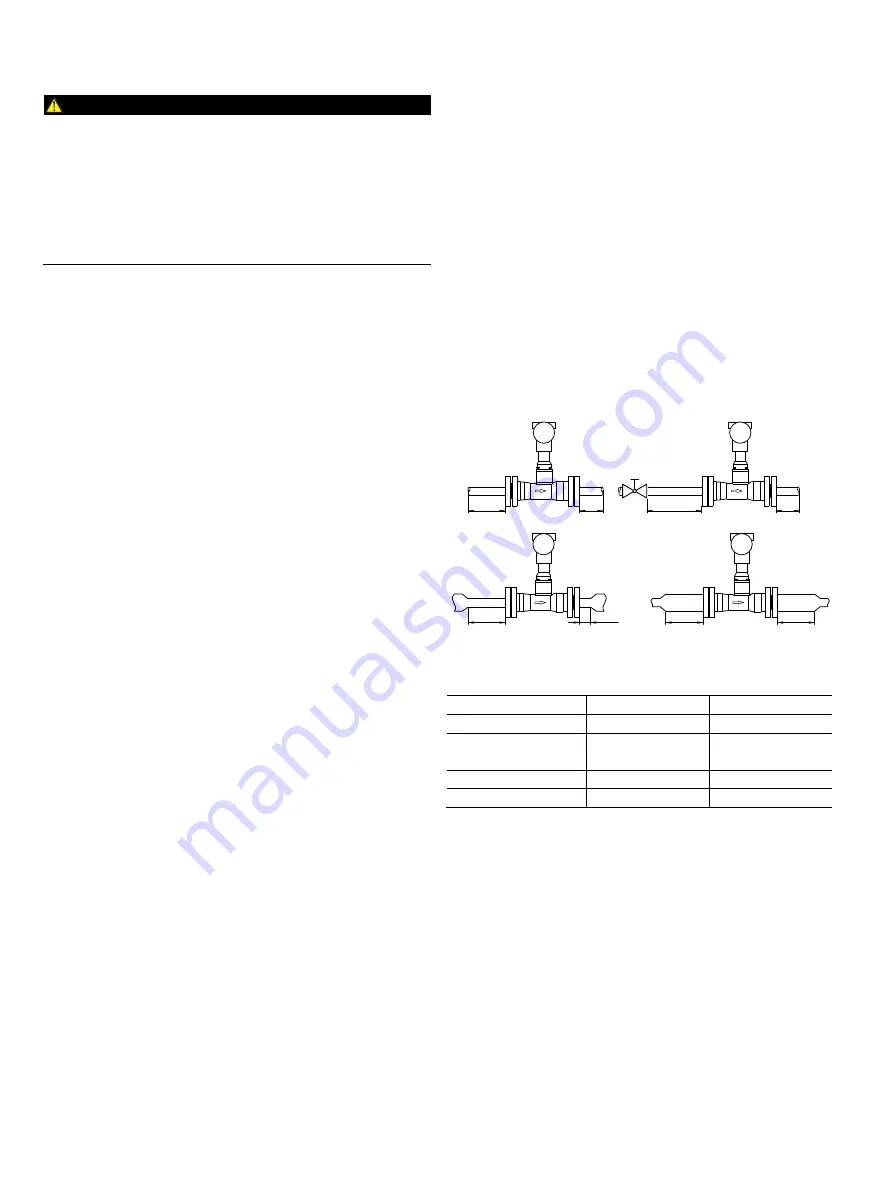

The figures below show the recommended inlet and outlet

sections for various installations.

Fig. 7:

Straight pipe sections

Installation

Inlet section

Outlet section

A

Straight pipe

min. 3 x DN

min. 1 x DN

B

Valve upstream of

the meter tube

min. 5 x DN

min. 1 x DN

C

Pipe reduction

min. 3 x DN

min. 1 x DN

D

Pipe extension

min. 3 x DN

min. 3 x DN

Additional inlet and outlet sections are not required

downstream of reductions with flange transition pieces in

accordance with DIN 28545 (α/2 = 8°).

G11753

≥3 x DN

≥3 x DN

A

B

C

D

≥3 x DN

≥ 1 x DN

≥5 x DN

≥1 x DN

≥3 x DN

≥1 x DN