ProcessMaster FEP610, HygienicMaster FEH610

| OI/FEP610/FEH610-EN Rev. B 7

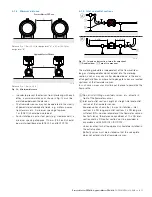

2.1.2

HygienicMaster

Integral mount design

Remote mount design

Fig. 2:

Designs

1

Flowmeter sensor

2

Remote transmitter

Flowmeter sensor

Model

HygienicMaster FEH611, FEH612

Housing

Integral mount design, remote mount design

Measuring accuracy for liquids

0.5 % of measured value

Permissible measuring medium

temperature T

medium

-25 ... 130 °C (-13 ... 266 °F)

Minimum conductivity

> 20 μS/cm (20 μS/cm for demineralized water)

Nominal pressure

PN 10 … 40, ASME CL 150, 300, JIS 10K

Nominal diameter

DN 3 ... 100 (1/10 “ ... 4 “)

Process connection

Wafer type design:

Flange in acc. with DIN, ASME or JIS:

Threaded pipe connection in acc. with DIN 11851

1)

:

Weld stubs

1)

:

Tri-Clamp in acc. with DIN 32676

1)

:

Tri-Clamp in acc. with ASME BPE

1)

:

External thread in acc. with ISO 228 / DIN 2999:

DN 3 ... 100 (1/10 ... 4“)

DN 3 ... 100 (1/10 ... 4“), PN 10 ... 40

DN 3 ... 100 (1/10 ... 4“), PN 10 ... 40

DN 3 ... 100 (1/10 ... 4“), PN 10 ... 40

DN 3 ... 100 (1/10 ... 4“), PN 10 ... 16

DN 3 ... 100 (1/10 ... 4“), PN 10

DN 3 ... 25 (1/10 ... 1“), PN 16

Process connection material

Stainless steel

Liner material

PFA (vakuum tight)

Electrode material

CrNi steel 1.4571 (AISI 316Ti), 1.4539 [904L], Hastelloy B, Hastelloy C, platinum-iridium, tantalum, titanium

IP rating

Integral mount design: IP 65 / IP 67

Remote mount design: IP 65 / IP 67 / IP 68 (sensor only)

Approvals

Pressure Equipment Directive

2014/68/EU

Conformity assessment in accordance with category III, fluid group 1

CRN (Canadian Reg.Number)

On request

Hygienic design approvals

3A, FDA-approved materials

Further approvals

At www.abb.com/flow or on request.

1) 3A

approved

G12002

2

1

1

FEH611

FEH612

FET612