67

AUTOM ATIC CONTROL U N IT, OM D8 0 0

AU TO M AT I C CO N T R O L U N I T, O M D 8 0 0

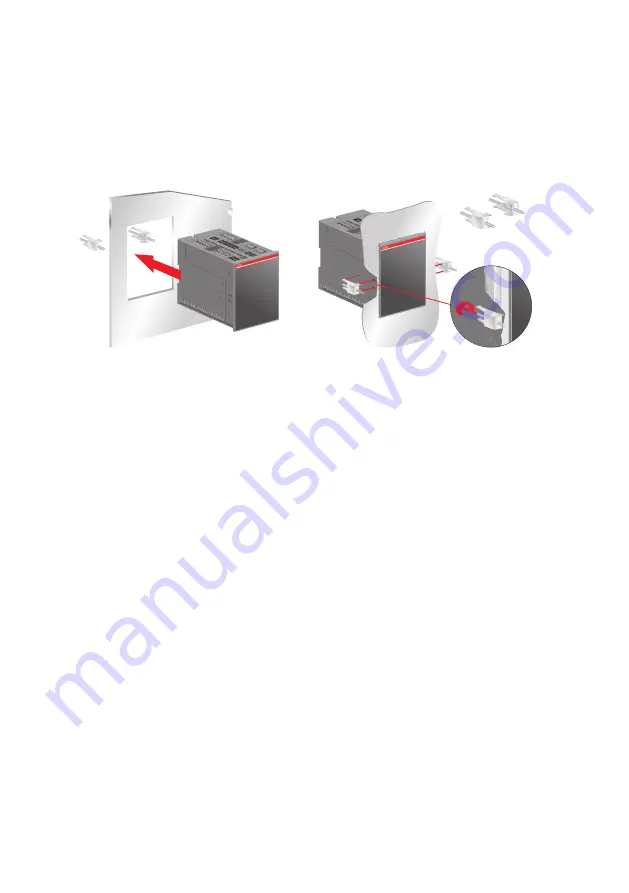

Figure 10.1

Fastener OMZD1, used when the automatic control unit OMD800 is mounted on the door

OMD

OMD

OMZD1

×2

K

A00

326

2

1

2b

2a

—

10 Accessories

—

10.1

Fastener