19

KM26 |

MAGNETIC LEVEL GAUGE | OI/KM26-EN REV I

The installation of insulation on KM26 units is dependent

upon the process temperatures and type of indicator used.

All temperatures referenced in insulation instructions refer to

process temperatures. For design temperature under 200 °F,

no insulation is required. If ordered, the insulation will be a

tied-on blanket (standard insulation attached to the scale

assembly). For 300 °F to 450 °F, an insulation pad is required

for magnetic bargraph (MBG) indication. If chamber

insulation is ordered in lieu of insulation pad, then the

insulation will be a pipe wrap blanket. For 450 °F to 500 °F,

pipe wrap blankets are mandatory for MBG indication. Before

installing any blanket or pad, note the location of all chamber

accessories to ensure a return to the proper working location.

Some units are built with limited accessory locations and the

accessories may not function if moved to new location.

. . . 3 Mounting

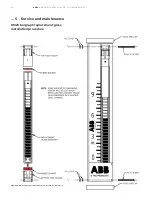

Figure 22 - side and front view of pipe wrap

Edges of the scale assembly can be sharp. Gloves and

proper care are required while working.

CAUTION

Insulation pads

To install insulation pads, simply remove the accessory from

the unit. Set the accessory on the pad. Using a razor, cut a

hole through the pad wherever a bracket or clamp exists.

Push the brackets or clamps through the hole and re-attach

the accessory to the previous location. Verify proper

operation and location.

The insulation thickness of a blanket is determined by the

process temperature. In all locations where scale indications,

switches, and transmitters are located, the insulation

thickness is thinned to ½ in. to facilitate magnetic coupling.

For all other locations the insulation thickness it governed by

the following:

• 0 to 250 °F (0 to 121 °C) ½ in. thickness ceramic fiber filler

with inner and outer silicone impregnated cloth covering

• 251 to 500 °F (122 to 260 °C) 1 in. thickness ceramic fiber

filler with inner and outer silicone impregnated cloth

covering

• 501 to 850 °F (261 to 454 °C) 1 in. thickness ceramic fiber

filler with outer silicone impregnated cloth covering and

4-ply high temp liner including TempKoat™ insulation

• 851 to 1000 °F (455 to 538 °C) 2 in. thickness ceramic fiber

filler with outer silicone impregnated cloth covering and

4-ply high temp liner including TempKoat™ insulation

For insulated units, it is critical to know the location of all

components attached to the unit when ordering the

insulation. Typically, the scale is located opposite to the

process connections and the insulation will be thinned down

to ½ in. on that side. If the scale has been moved from the

position that it is shipped in, then the thinned insulation will

not be in the correct location. When ordering, ABB refers to

location by a clock system with the process connections at 12

o’clock when looking down on the unit from above. The scale

is typically at 6 o’clock. Openings for the connections are

made on the basis of the orientation specified by the

customer. Thinning of insulation is needed for switches and

transmitters as well and their positions must also be known.

Pipe wrap blanket

For pipe wrap blankets, installation requires the removal of

scale assembly and transmitter (if installed). If a transmitter

is installed, note its location and undo the front of the

brackets (not the gear clamps) and remove the transmitter.

Switches on switch mount rods will have to be rotated away

from the chamber. Wrap the insulation blanket around the

unit and fasten it with the Velcro straps. If a transmitter was

installed, feel for the brackets under the insulation and mark

their location with a marker. Sew a 1 in. square through the

blanket around the marks. Using a razor, cut an X from corner

to corner of the square making sure not to break the new

seam. Push the brackets through the new holes. Set the

scale assembly against the insulation at proper mounting

location. Draw a mark on each side of each gear clamp next

to the scale channel. This location on the insulation should

have sewn seams down the length of the blanket to prevent

fraying. It is recommend that the marks for each clamp be

sewn around to reduce fraying. Using a razor, cut through the

insulation to allow the gear clamp to pass through the hole.

Once a hole is made for each clamp, remove the blanket from

the unit. Feed the gear clamps of the scale assembly through

the holes so that each end of the clamp goes through. Set

the scale assembly and insulation blanket against the unit

and use the gear clamps to fasten the parts to the unit. Make

sure that the screw for the clamp does not interfere with the

transmitter or switch locations. If applicable, feed the

brackets for the transmitter through their holes in the

blanket. Attach the velcro closures on the back of the blanket.

Rotate any switches back into position. Re-attach the

transmitter at the proper location. Verify the operation of all

devices. An inoperative switch may need to be pressed

tighter to the unit. Transmitters should be checked for the

correct zero point and slid up or down to set to proper level.

Insulation instructions