2.3

Maintenance

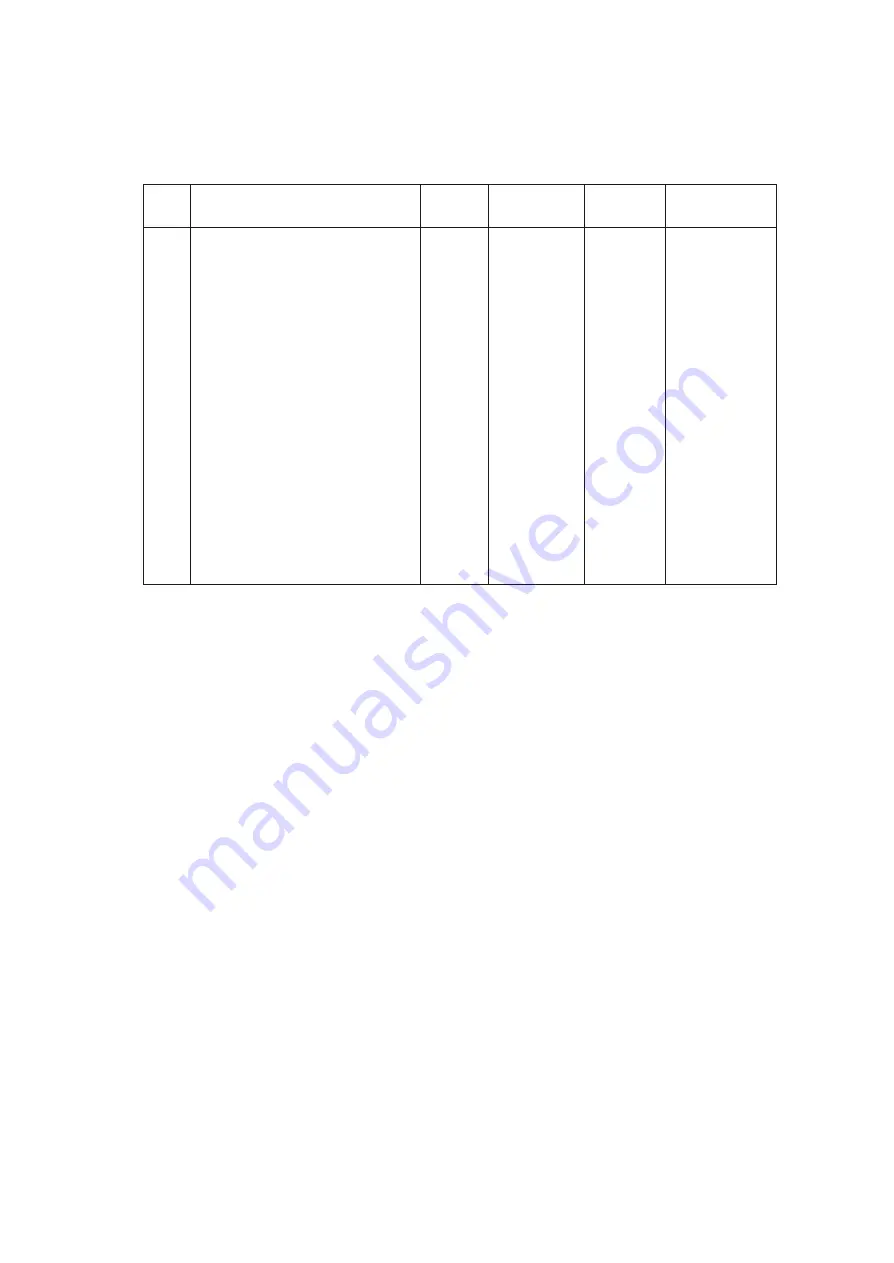

2.3.1 Maintenance schedule (As per Drg. 1VYN400290-005 Pg. 11 & 12)

Sr.

Description

Before Interval

Interval Every

No.

Start up of 6 months of 5 years 1000 operation

01

CHECKING OF OPERATING

MECHANISM.

1.1

Checking of fastener tightness fig. 7A

Item B. H. L. & M.

a

a

----

a

1.2

Checking of shock absorbers for

Leakage or stuck-up fig. 7A item F & G

a

a

----

a

1.3

Checking of top & bottom trip free

mechanism, cap & coupling

Fig. 7A, item J & K

a

a

----

a

1.4

Closing & Tripping spring assembly

& split pin (N) on them (fig. 7A)

----

----

----

a

1.5

Bearing item (P) fig. 7A

----

----

----

a

1.6

Checking of setting

*Coupling and knife catch gap

(Setting 1, fig. 7B)

*Bottom TFM and CAP gap

(Setting 2, fig. 7A) both gaps should

be between 1 - 2 mm

a

a

----

a

1.7

Spring cut off micro switches.

a

a

----

a

02

OVERHAUL & LUBRICATION OF

CHARGING DEVICE AND

OPERATING GEAR

----

----

a

----

03

GAS PRESSURE CHECK

a

a

a

a

NOTE

1) Complete overhaul of circuit breaker with replacement of poles to be done after 10,000 operations.

2) Ask ABB for details of overhaul procedures.

(10)

Summary of Contents for HPA 12kV

Page 7: ...Fig 3b HPA breaker pole for 36 kV ...

Page 9: ... 7 Fig 5 Circuit Breaker ...

Page 13: ...Fig 7A Maintenance schedule for frequently operated breaker type HPA 1VYN400290 005 11 ...

Page 14: ...Fig 7B Maintenance schedule for frequently operated breaker type HPA 1VYN400290 005 12 ...

Page 15: ...Electrical endurance HPA 13 ...

Page 29: ......