(9)

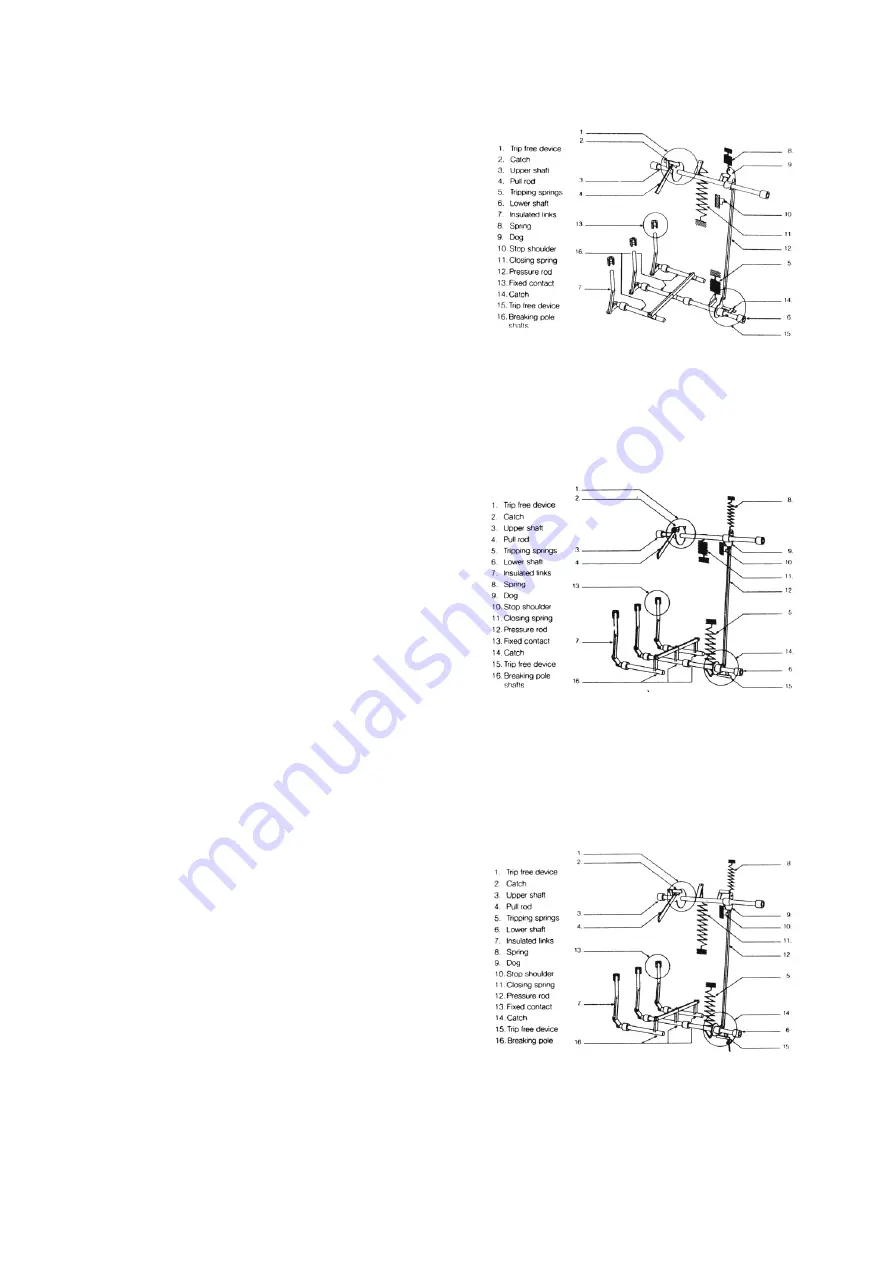

Operating Mechanism Working Principle:

Fig. 6A shows the operating device with

the breaker in the open position. The

closing spring (11) is charged if the latch

(2) is tripped, the upper shaft is released,

its turning is transmitted via link (12) to

the breaker pole shafts (6).

In fig. 6B the breaker has closed and at

the same time the opening spring (5) has

been charged. Driving disc (9) comes to

rest against stop (10) which, via link (12)

and trip free device (14) also prevents the

opening spring turning the breaker pole

shaft (6). Now the charging device starts

and link (4) moves upwards until latch (2)

is engaged. At this point link (4) turns and

begins to move downwards, whereupon

the upper shaft turns and retentions. The

closing spring position is reached

according to fig. 6C.

During the breaker opening, latch (14) is

released, thus releasing the lower shaft

which via the insulating links (7), actuates

the moving contact of the breaker poles,

for interruption. The spring (8) returns the

link (12) with the associated driving pin

and the operating device to the position in

fig. 6A.

For rapid re-closing the associated

switchgear cubicles can be fitted with

suitable relay equipment. The HPA can

be fitted with two opening coils, one

closing coils.

Fig - 6A

Fig - 6B

Fig - 6C

Summary of Contents for HPA 12kV

Page 7: ...Fig 3b HPA breaker pole for 36 kV ...

Page 9: ... 7 Fig 5 Circuit Breaker ...

Page 13: ...Fig 7A Maintenance schedule for frequently operated breaker type HPA 1VYN400290 005 11 ...

Page 14: ...Fig 7B Maintenance schedule for frequently operated breaker type HPA 1VYN400290 005 12 ...

Page 15: ...Electrical endurance HPA 13 ...

Page 29: ......