ACQ550-U1 User’s Manual

113

Group 21: START/STOP

This group defines how the motor starts and stops. The ACQ550 supports several

start and stop modes.

Code Description

2101

START FUNCTION

Selects the motor start method. The valid options depend on the value of parameter 9904

MOTOR

CTRL

MODE

.

1 =

AUTO

– Selects the automatic start mode.

• Vector control mode: Optimal start in most cases. The drive automatically selects the correct output frequency to

start a rotating motor.

•

SCALAR

:

FREQ

mode: Immediate start from zero frequency. Identical to selection 8 =

RAMP

.

2 =

DC

MAGN

– Selects the DC Magnetizing start mode.

Note:

The DC Magnetizing start mode cannot start a rotating motor.

Note:

The drive starts when the set pre-magnetizing time (parameter 2103

DC

MAGN

TIME

) has passed, even if motor

magnetization is not complete.

• Vector control modes: Magnetizes the motor within the time determined by the parameter 2103

DC

MAGN

TIME

using DC current. The normal control is released exactly after the magnetizing time. This selection guarantees

the highest possible break-away torque.

•

SCALAR

:

FREQ

mode: Magnetizes the motor within the time determined by the parameter 2103

DC

MAGN

TIME

using

DC current. The normal control is released exactly after the magnetizing time.

3 =

SCALAR

FLYST

– Selects the flying start mode.

• Vector control modes: Not applicable.

•

SCALAR

:

FREQ

mode: The drive automatically selects the correct output frequency to start a rotating motor – useful

if the motor is already rotating and if the drive will start smoothly at the current frequency.

• Cannot be used in multimotor systems.

4 =

TORQ

BOOST

– Selects the automatic torque boost mode (

SCALAR

:

FREQ

mode only).

• May be necessary in drives with high starting torque.

• Torque boost is only applied at start, ending when output frequency exceeds 20 Hz or when output frequency is

equal to reference.

• In the beginning the motor magnetizes within the time determined by the parameter 2103

DC

MAGN

TIME

using DC

current.

• See parameter 2110

TORQ

BOOST

CURR

.

5 =

FLY

+

BOOST

– Selects both the flying start and the torque boost mode (

SCALAR

:

FREQ

mode only).

• Flying start routine is performed first and the motor is magnetized. If the speed is found to be zero, the torque

boost is done.

8 =

RAMP

– Immediate start from zero frequency.

2102

STOP FUNCTION

Selects the motor stop method.

1 =

COAST

– Selects cutting off the motor power as the stop method. The motor coasts to stop.

2 =

RAMP

– Selects using a deceleration ramp.

• Deceleration ramp is defined by 2203

DECELER

TIME

1 or 2206

DECELER

TIME

2 (whichever is active).

2103

DC MAGN TIME

Defines the pre-magnetizing time for the DC Magnetizing start mode.

• Use parameter 2101 to select the start mode.

• After the start command, the drive pre-magnetizes the motor for the time defined here and then starts the motor.

• Set the pre-magnetizing time just long enough to allow full motor magnetization. Too long a time heats the motor

excessively.

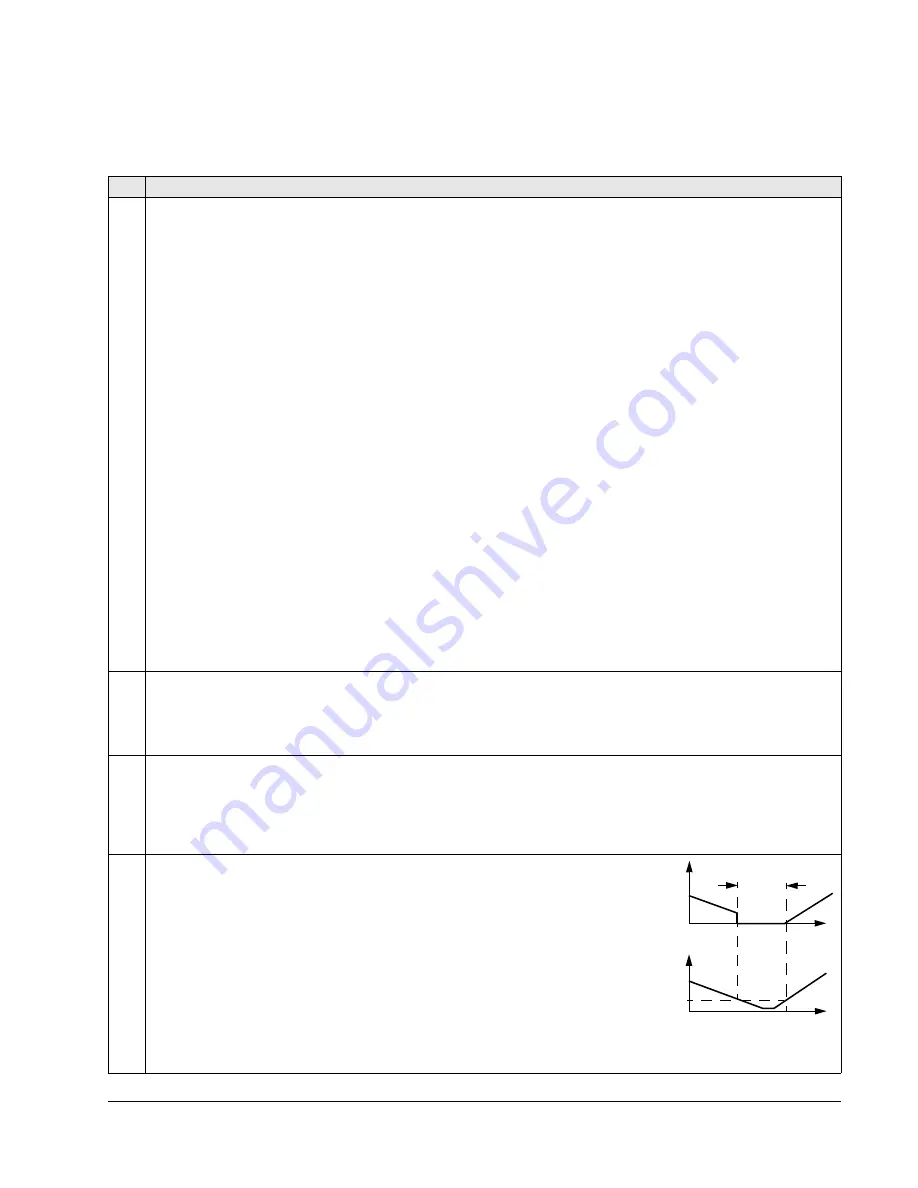

2104

DC HOLD CTL

Selects whether DC current is used for braking or DC Hold.

0 =

NOT

SEL

– Disables the DC current operation.

1 =

DC

HOLD

– Enables the DC Hold function. See the diagram.

• Requires parameter 9904

MOTOR

CTRL

MODE

= 1 (

VECTOR

:

SPEED

)

• Stops generating sinusoidal current and injects DC into the motor when

both the reference and the motor speed drop below the value of parameter

2105.

• When the reference rises above the level of parameter 2105 the drive

resumes normal operation.

2 =

DC

BRAKING

– Enables the DC Injection Braking after modulation has

stopped.

• If parameter 2102

STOP

FUNCTION

is 1 (

COAST

), braking is applied after start is removed.

• If parameter 2102

STOP

FUNCTION

is 2 (

RAMP

), braking is applied after ramp.

speed

Ref

DC hold

DC hold

Motor

speed

T

T

Summary of Contents for ACQ550-U1-011A-6

Page 1: ...ACQ550 User s Manual ACQ550 U1 Drives 1 200 hp ...

Page 4: ......

Page 10: ...10 ACS550 U1 User s Manual Table of contents ...

Page 42: ...42 ACQ550 U1 User s Manual Start up control with I O and ID Run ...

Page 56: ...56 ACQ550 U1 User s Manual Control panel ...

Page 68: ...68 ACQ550 U1 User s Manual Application macros ...

Page 250: ...250 ACQ550 U1 User s Manual Fieldbus adapter ...

Page 266: ...266 ACQ550 U1 User s Manual Maintenance ...

Page 314: ...314 ACQ550 U1 User s Manual Index ...