6

Warning: Abatement Technologies air filtration systems are not intrinsically safe for use in hazardous

environments. Always consult a certified industrial hygienist before using them. Do NOT use this

equipment in any atmosphere that is or may be immediately dangerous to life or health (IDLH),

combustible, flammable, explosive, oxygen deficient, and/or contains odors, vapors, gases or

particulates that exceed permissible exposure levels. Such atmospheres may require the use of

intrinsically safe equipment, specific engineering controls, and personal protective equipment in

accordance with Occupational Safety and Health Administration (OSHA), Environmental Protection

Agency (EPA), Canadian Standards Association (CSA), and other federal, state, provincial and local

regulations.

Warning: This equipment is not classified as “intrinsically safe” and should not be used in the

following hazardous locations as defined by the Underwriters Laboratories: Class I Division 1,

Class I Division 2, Class I Zone 0, Class I Zone 1, Class I Zone 2, Class II Division 1, Class II

Division 2, Class III Division 1, Class III Division 2. Refer to the UL web site: http://www.ul.com/

hazloc/define.htm.

Warning: Do not use this unit near sparks, open flames or other possible sources of ignition.

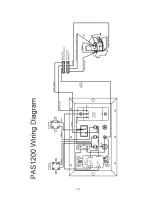

PAS1200 CONTROL PANEL

1. Power Cord

- Hardwired, 10 foot power cord for

connection to electrical outlet.

2. Speed Control Switch

- Serves as the power

switch and provides a variable adjustment to the

speed of the motorized impeller.

3. Power Indicator

- Green light that indicates speed

control switch is “ON” and system is connected to

power source.

4. Hour Meter

- Provides a count of the total operating

hours.

5. Filter Change Indicator - Primary

– Amber light that indicates excessive restriction on air intake or

loading of the pre-filter(s) and that filter change procedures should be followed.

6. Filter Change Indicator - HEPA

- Amber light that indicates excessive restriction on air exhaust or

loading of the HEPA filter and that filter change procedures should be followed.

7. Circuit Breaker -

10 amp circuit breaker that provides protection for the unit’s electrical components.

8. GFCI Receptacle

- Electrical safety device that will trip and stop the flow of electricity if leakage of

current is detected from the unit or an electrical device plugged into the GFCI receptacle. The PAS1200

can supply a total of 7 amps of electrical power for additional equipment that is connected to the GFCI

receptacle.

Do not exceed this 7 amp limit.

Note

: If the equipment connected to the GFCI receptacle draws more than a total of 7 amps, the circuit

breaker on the control panel and/or the building breaker will trip. This condition can be remedied only by

reducing the total amperage draw.

BEFORE OPERATING THE UNIT, NOTE THE FOLLOWING

:

The rear axle, 2 rear wheels, 2 bushings for securing the wheels to the axle and an Allen wrench are packed

in a separate box that is included with the PAS1200. Place the axle through the circular opening in the lower

rear section of the cabinet and center the axle. Slide the wheels and bushings onto the axle and tighten the

bushings in place using the Allen wrench. Refer to Figure A.

Inspect and tighten any HEPA filter retaining nuts that may have loosened during transportation. Inspect the

filters for any material or structural damage prior to use and replace any damaged filters before operating the

unit. When removing any filters prior to operation, always put them back in place with airflow indicator on filter

housing oriented in the proper direction (if applicable).