Installing MX-ONE

Figure 47

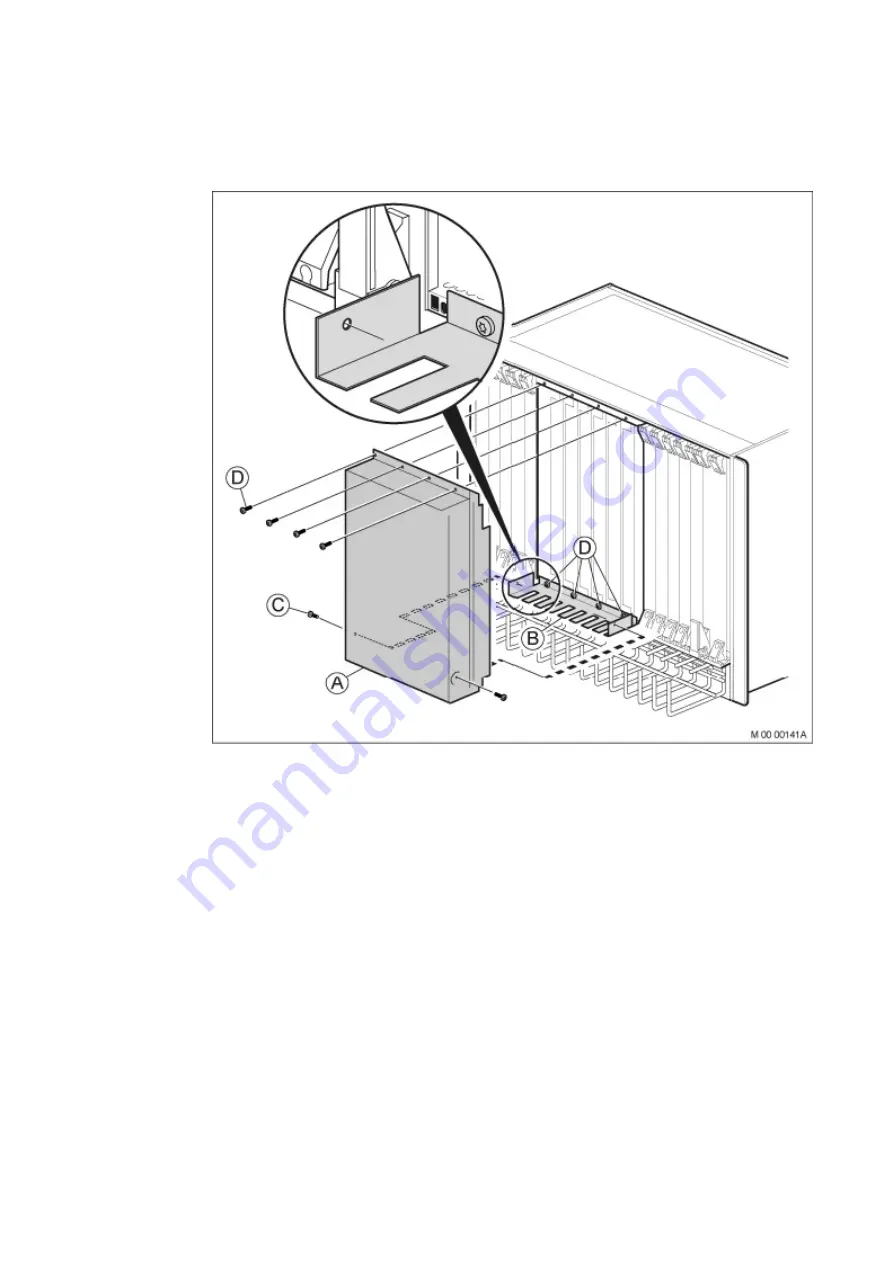

Installing the Board Cover

Note:

The board cover must be installed to fulfill the EMC requirement.

1

Fasten the finger plate (B) using four screws (D), Page 64 .

2

Fasten the board cover (A) above the finger plate using four screws (D) on

the top part, and the two screws (C) on the bottom part, Page 64 .

3

Install board cover on the other subrack in the same way.

4.9

Installing the Fan Unit

This section describes the installation of fan unit and upper air plate in the

cabinet.

Note:

If only one subrack is to be installed the fan unit must be strapped for

being fed from only one DC/DC converter.

64

6/1531-ASP 113 01 Uen J2 2008-07-17

Summary of Contents for MX-ONE

Page 1: ...Installing MX ONE INSTALLATION INSTRUCTIONS...

Page 6: ...Installing MX ONE 6 1531 ASP 113 01 Uen J2 2008 07 17...

Page 10: ...Installing MX ONE Figure 1 MX ONE Cabinets 4 6 1531 ASP 113 01 Uen J2 2008 07 17...

Page 26: ...Installing MX ONE 20 6 1531 ASP 113 01 Uen J2 2008 07 17...

Page 72: ...Installing MX ONE Figure 49 Installing Slides 66 6 1531 ASP 113 01 Uen J2 2008 07 17...

Page 107: ...Cabling Figure 79 Cable Connections Configure Example 101 6 1531 ASP 113 01 Uen J2 2008 07 17...

Page 111: ...Cabling Figure 81 ESU Front Connectors and LEDs 105 6 1531 ASP 113 01 Uen J2 2008 07 17...

Page 122: ...Installing MX ONE 116 6 1531 ASP 113 01 Uen J2 2008 07 17...

Page 134: ...Installing MX ONE 128 6 1531 ASP 113 01 Uen J2 2008 07 17...

Page 146: ...Installing MX ONE 140 6 1531 ASP 113 01 Uen J2 2008 07 17...

Page 148: ...Installing MX ONE 142 6 1531 ASP 113 01 Uen J2 2008 07 17...

Page 156: ...Installing MX ONE 150 6 1531 ASP 113 01 Uen J2 2008 07 17...