4

Pump Motors

A.O.Smith

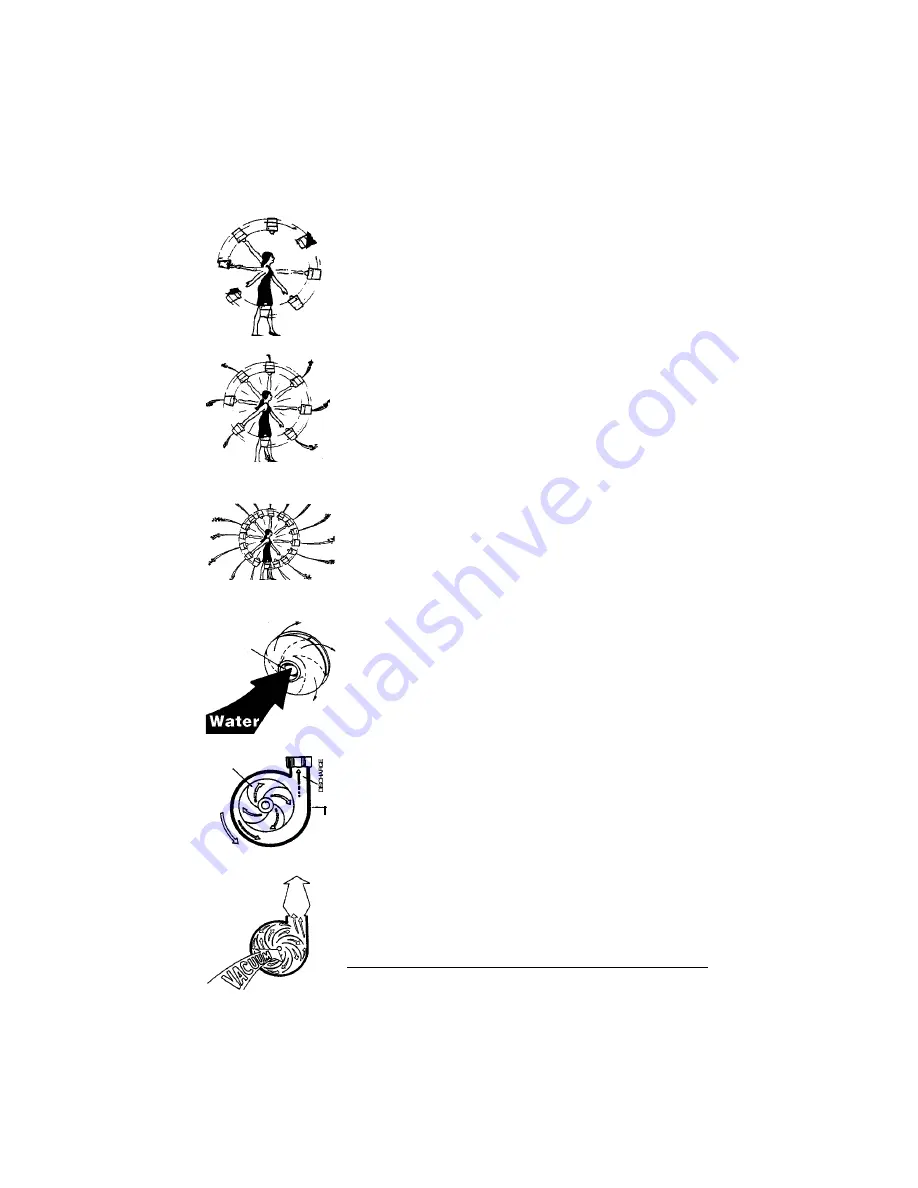

The principle of operation can be demonstrated

by a whirling bucket of water. As the bucket is

rotated (figure 1), the water is held in the bucket

by centrifugal force. If we were to punch a hole

in the bottom of the bucket, the water would be

forced out, again by centrifugal force (figure 2).

Speeding up the rotation of the bucket, the water

would exit with greater force (figure 3).

This same principle is performed by the

impeller of the pump. As the motor turns the

impeller, the water is forced through the impeller

vanes toward the outside edge (figure 4). The

spinning action of these vanes generates cen-

trigual force (figure 5). This action imparts

kinetic or velocity energy into the water. As the

water is propelled to the outer edge of the

impeller, there is a reduction in pressure at the

eye of the impeller, creating a “vacuum” (figure

6).

The combination of atmospheric pressure on

the surface of the water and vacuum at the eye of

the impeller, causes the water to flow in the “suc-

tion pipe” to the pump.

The amount of pressure imparted into the

water by the impeller is determined in part by

the size and design of the impeller which also

effects forces placed on the motor. There are

basically two types of impellers used on these

applications; the semi-open has vanes exposed on

the front or receiving side. The back side is

closed by a shroud (figure 7). A closed impeller is

designed to have two shrouds completely enclos-

ing the vane area of the impeller (figure 8).

IMPELLER

ROTATION OF

IMPELLER

FLOW

UNDER

PRESSURE

VOLUTE

5

6