35

1.

Remove main burners from unit.

2. Check that burner venturi and ports are free of foreign matter.

3. Clean burners with bristle brush and/or vacuum cleaner 3/4"

DO NOT distort burner ports or pilot location.

4. Reinstall burners in unit. Making sure front and rear of burners

are installed correctly in burner support brackets.

Also check for good flow of combustion and ventilating air to the

unit. Maintain a clear area around the boiler at all times.

After placing the boiler in operation check the ignition system safety

shutoff devices for proper operation. To accomplish this with the

main burners operating, close the pilot adjusting valve on the left

side of the manifold. Within four seconds the main burners and

pilot should extinguish and the spark igniter on the pilot assembly

should begin sparking. If this does not occur immediately,

discontinue gas supply by closing main manual shutoff and call a

qualified serviceman to correct the situation. If the burners

extinguish, and pilot assembly begins sparking, the system is

operating correctly so discontinue electrical power, open pilot

adjusting valve, and light boiler in accordance with lighting and

operating instructions.

For installations above 2000 feet (600 m), refer to HIGH ALTITUDE

INSTALLATIONS in the installation section.

PRE-TROUBLE-SHOOTING

Before any extensive trouble-shooting, perform the following:

Ensure that:

— Power (120 vac) is supplied to the appliance.

— System control (tank temperature control, thermostat, etc.) is

calling for appliance operation (call for heat).

— Other contacts (switches) are closed (transformer relay, low

water cutoff, flow switch, limit controls, pressure switches, etc.)

— Gas supply pressure is within the maximum and minimum

operating ranges listed on the appliance rating plate/label.

— Voltage (24 vac) is supplied by transformer.

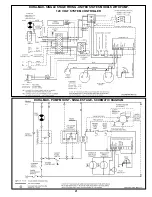

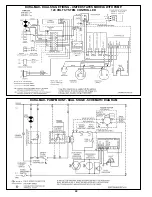

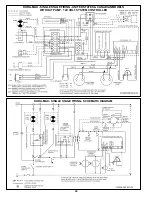

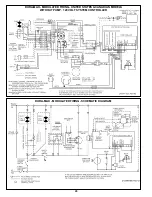

— Appliance is wired according to wiring diagram.

NOTE: Cross wiring the 24 volt circuit of the relay will short the

transformer.

—

All wire terminals/connectors are firmly attached to valves,

modules, switches, limit controls, etc.

—

There has been no damage caused by freezing, inoperative

pumps, etc.

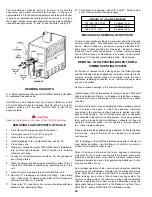

SYSTEM OPERATION

CHECKOUT SEQUENCE

CORRECT

INCORRECT

CAUSE

REMEDY

Set tank/system temperature

Circulating pump

Pump and burner

Temp. control

Replace.

control (thermostat) 20°F (12°C)

and burner

remain on.

(thermostat) defective.

below tank water temperature.

shutoff.

System wiring

Correct wiring.

incorrect

With thermal

Circulating pump

Pump wired for

Correct wiring.

balancer, pump

on.

continuous operation.

off delay of

Burner on.

Gas valve stuck

Correct or replace

approximately

or defective.

valve.

two minutes.

System wiring is

Correct wiring.

incorrect.

Set tank/system temperature

Circulating pump

Circulating pump

Auto reset high limit

Replace. (If problem

control (thermostat) 20°F

and burner on.

on.

control set too low.

proven to be at this

(12°C) above tank/system

control by applying

water temperature.

Auto reset high limit control

jumper to terminals).

differential too wide.

System wiring is

Correct wiring.

incorrect.

Manual reset high limit

Depress reset

switch has activated.

button.

Gas valve or wiring

defective.

Circulating pump

Power off or system

Check power supply

and burner off.

wiring is incorrect.

and wiring.

Temp. control

Replace.

(thermostat) defective.

Burner on.

System wiring is

Correct wiring.

incorrect.

Boiler outlet temperature

Circulating pump.

Circulating pump

Auto reset high limit control

Replace.

exceeds 210°F (98°C) hot water

and burner on.

defective, or set too

supply, 250°F (120°C) hydronic

high (max. should

supply.

be set at 200°F [93°C] hot

water supply, 240°F

[115°C] hydronic supply).

Set tank/system temperature

System maintains

control (thermostat) for desired

desired water

water temperature.

temperature.

TROUBLE-SHOOTING