10

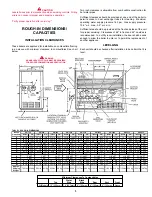

TABLE 5

Multipliers To Be Used With Table 1 When Applying The

Gravity Factor To Other Than .60 Specific Gravity

Specific

Specific

Gravity

Multiplier

Gravity

Multiplier

.35

1.31

1.00

.78

.40

1.23

1.10

.74

.45

1.16

1.20

.71

.50

1.10

1.30

.68

.55

1.04

1.40

.66

*.60 (Nat.)

1.00

*1.50 (Prop.)

.63

.65

.96

1.60

.61

.70

.93

1.70

.59

.75

.90

1.80

.58

.80

.87

1.90

.56

.85

.84

*2.00 (Butane)

.55

.90

.82

2.10

.54

*Use these correction factors if exact specific gravity of the gas is not known.

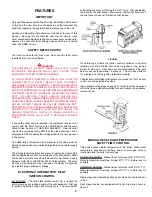

PURGING

Gas line purging is required with new piping or systems in which

air has entered.

CAUTION

PURGING SHOULD BE PERFORMED BY PERSONS

EXPERIENCED IN THIS TYPE OF GAS SERVICE TO AVOID RISK

OF FIRE OR EXPLOSION. PURGE DISCHARGE MUST NOT

ENTER CONFINED AREAS OR SPACES WHERE IGNITION CAN

OCCUR. THE AREA MUST BE WELL VENTILATED AND ALL

SOURCES OF IGNITION MUST BE INACTIVATED OR REMOVED.

BEFORE PLACING THE BOILER IN OPERATION, CHECK FOR

GAS LEAKAGE. Use soap and water solution or other material

acceptable for the purpose in locating gas leaks. DO NOT USE

MATCHES, CANDLES, FLAME OR OTHER SOURCES OF

IGNITION FOR THIS PURPOSE.

1.

CORRECT GAS

Make sure the gas on which the boiler will operate is the same as

that specified on the boiler rating plate. Do not install the boiler if

equipped for a different type gas, consult your gas supplier. These

boilers are designed to operate on natural gas only.

2A. SIZING GAS SUPPLY LINE (For single boiler installations

and for installations of multiples of two or three of same size

boilers).

Use table 1, which is taken from ANSI booklet Z223.1, NATIONAL

FUEL GAS CODE, and/or CAN/CSA-B149.1-00 to size iron pipe

or equivalent gas supply line. Table 4 is based on a pressure drop

of 0.3 inches of water and a specific gravity of 0.60 which is

approximately for natural gas. (LP gas has an S.G. of about 1.53).

If the service pressure is five inches water column or less, use one

pipe size larger than specified in table 1 in order to minimize pressure

drop in the line.

2B.

SIZING GAS SUPPLY LINE (For multiples of over three boilers

of same size or for multiple installations of two or more mixed

sizes).

Capacities in cubic feet per hour of 0.60 specific gravity gas for

different sizes and lengths are shown in table 4. No additional

allowance is necessary for an ordinary number of fittings.

Where it is necessary to use more than the average number of

pipe fittings i.e. elbows, tees, and valves in gas supply line, use a

pipe larger than specified to compensate for increased pressure

drop.

TABLE 4

MAXIMUM CAPACITY OF PIPE IN CUBIC FEET OF GAS PER HOUR (BASED UPON A PRESSURE DROP OF

0.3 INCH WATER COLUMN AND 0.6 SPECIFIC GRAVITY GAS)

Length in Feet (Meters)

Nominal Iron Pipe Size, Inches (NPT)

From Gas Meter

1/2

3/4

1

1 1/4

1 1/2

2

2 1/2

3

4

10 (3)

132

278

520

1,050

1,600

3,050

4,800

8,500

17,500

20 (6)

92

190

350

730

1,100

2,100

3,300

5,900

12,000

30 (9)

73

152

285

590

890

1,650

2,700

4,700

9,700

40 (12)

63

130

245

500

760

1,450

2,300

4,100

8,300

50 (15)

56

115

215

440

670

1,270

2,000

3,600

7,400

60 (18)

50

105

195

400

610

1,150

1,850

3,250

6,800

70 (21)

46

96

180

370

560

1,050

1,700

3,000

6,200

80 (24)

43

90

170

350

530

990

1,600

2,800

5,800

90 (27)

40

84

160

320

490

930

1,500

2,600

5,400

100 (30)

38

79

150

305

460

870

1,400

2,500

5,100

125 (38)

34

72

130

275

410

780

1,250

2,200

4,500

150 (46)

31

64

120

250

380

710

1,130

2,000

4,100

175 (53)

28

59

110

225

350

650

1,050

1,850

3,800

200 (61)

26

55

100

210

320

610

980

1,700

3,500

*The heating value of natural gas is approximately 1050 Btu/ft³.

Propane (L.P.) gas has a heating value of approximately 2500 Btu/ft³.