69

6

HH&ORVHG6\VWHPVDQG

7KHUPDO([SDQVLRQRQSDJH

6

HH:

DWHU/LQH&RQQHFWLRQVRQSDJH

,I

D

SXPS

LV

EHLQJ

LQVWDOOHG

EHWZHHQ

D

ZDWHU

KHDWHU

DQG

VWRU

DJH

WDQN

RU

RQ

D

EXLOGLQJ

UHFLUFXODWLRQORRSZLUHDFFRUGLQJWR)LJXUHRQSDJH

,I

D

SXPS

LV

EHLQJ

LQVWDOOHG

LQ

D

UHFLUFXODWLRQ

ORRS

EHWZHHQ

W

KH

ZDWHU

KHDWHU

DQG

D

FRPPHUFLDOGLVKZDVKHUZLUHDFFRUGLQJWR)LJXUHRQSDJH

W

A

TER PIPING DIAGRAMS

%HIRUHLQVWDOODWLRQRIZDWHUSLSLQJUHYLHZWKHIROORZLQJ

6

HH0L[LQJ9

DOYHVRQSDJH

6

HH'LVKZDVKLQJ0DFKLQHVRQSDJH

6

HH

7HPSHUDWXUH3UHVVXUH5HOLHI9

DOYHRQSDJH

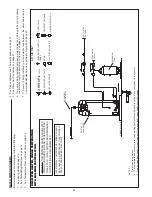

ONE WATER HEATER, TWO TEMPERATURE WITH HIGH TEMPERAURE LOOP RECIRCULATION WITH BUILDING RECIRCULATION

NOTES:

1.

Preferred piping method

.

2.

The temperature and pressure relief valve setting shall not exceed pressure rating of any component in the system

.

3.

Service valves are shown for servicing unit. Howeve

r,

local codes shall govern their usage.

LEGEND

TEMPERA

TURE &

PRESSURE RELIEF V

A

L

V

E

PRESSURE RELIEF V

A

L

V

E

CIRCULA

TING PUMP

TEMPER

A

T

URE CONTRO

L

PROBE

DRAIN

FULL

POR

T

BALL

V

A

L

V

E

MIXING V

A

L

V

E

TEMPERA

TURE GAGE

W

A

TER FLOW SWITCH

CHECK V

A

L

V

E

W

ARNING:

THIS DRA

WING SHOWS SUGGESTED

PIPING CONFIGURA

TION

AND OTHER DEVICES;

CHECK WITH LOCAL

CODES

AND ORDINANCES

FOR ADDITIONAL

REQUIREMENTS.

ANY

MA

TERIAL, COMPONENT

OR VENDOR CHANGE

MUST

HA

VE PRIOR

APPROV

AL

BY

THE

APPLICABLE

PRODUCT

ENGINEERING DEP

A

R

T

MENT

.

FINISHED FLOOR

HOT WATER

RETURN

OUTLET

HOT

TEMPERED WATER

RETURN

TEMPERED

WATER

OUTLET

PIPE T&P TO

OPEN DRAIN

COLD WATER

SUPPLY

COLD

EXPANSION

TANK

Summary of Contents for BTH 300

Page 66: ...66 WIRING DIAGRAM Figure 58 ...