26 • Condensing Models: On-Demand Water Heater Service Handbook

SER

VICE PR

OCEDURE

S

strong reasons to do so (e.g., high

elevation installations).

Checking the Manifold

Gas Pressure

1. Verify that the gas supply pressure

is within the correct operating

range when the heater fires at

maximum combustion. (Incorrect

gas supply pressure will affect the

gas manifold pressure.)

2. Ensure that the unit is not in operation.

3. Remove the screw from the

manifold port (Figure 14, p. 26).

4. Connect a manometer to the

manifold port using a tube. Ensure

that this connection is secure

enough to prevent a gas leak.

5. Run water (3.5 GPM or more) to

activate operation. It is suggested

that you draw a large amount of

flow to prevent overheating during

maximum burn. If presence of a

gas leak is detected, immediately

shut off the unit and inspect

the tube/manifold connection.

Otherwise, proceed to the next

step.

6. Check the manifold gas pressures:

•

To check the manifold gas

pressure during maximum

combustion, press and hold the

“MAX” button on the computer

board. (See Figure 8, page

18).

•

To check the manifold pressure

during minimum combustion,

press and hold the “MIN” button

on the computer board (Figure 8,

page 18).

•

The desired pressures are listed

on the “Specifications” page

(page 4).

7. When you are finished, deactivate

the water heater, remove the

manometer tube, and replace the

port screw.

However, If the manifold pressures

do not match up with those listed

on the rating plate, adjust the

manifold pressure. To do so, refer

to the following procedures.

Adjus ng Maximum Manifold

Pressure

WARNING! Complete the

following procedure ONLY if you have

been instructed to do so by the

Technical Service Department.

1. Ensure that the water heater is not

in operation.

2. Remove the screw from the

manifold port (Figure 14).

3. Connect a manometer to the

manifold port using a tube. Ensure

that this connection is secure

enough to prevent gas leak.

4. Run water through the water

heater to activate its operation. If

presence of a gas leak is detected,

immediately shut off the water

heater and inspect the tube/

manifold connection. Otherwise,

proceed to the next step.

5.

During this step, DO NOT press the

“Increase” or “Decrease” button for

more than two seconds at a time.

Press and hold down the “MAX”

button on the computer board

(Figure 8, page 18).

While holding down the “MAX”

button, press either the “Increase”

or “Decrease” button to increase

or decrease the manifold gas

pressure, respectively (Figure 8,

page 18). Use the manometer

to verify that pressure has been set

to the desired value.

6. After the gas pressure has been

set, deactivate the water heater,

remove the manometer tube, and

replace the port screw.

7. Verify proper operation.

Adjus ng Minimum Manifold

Pressure

WARNING! Complete the

following procedure ONLY if you have

been instructed to do so by the

Technical Service Department.

1. Ensure that the water heater is not

in operation.

2. Remove the screw from the

manifold port of the water heater

(Figure 14).

3. Connect a manometer to the

manifold port using a tube. Ensure

that this connection is secure

enough to prevent gas leak.

4. Run water through the water

heater to activate its operation. If

presence of a gas leak is detected,

immediately shut off the water

heater and inspect the tube/

manifold connection. Otherwise,

proceed to the next step.

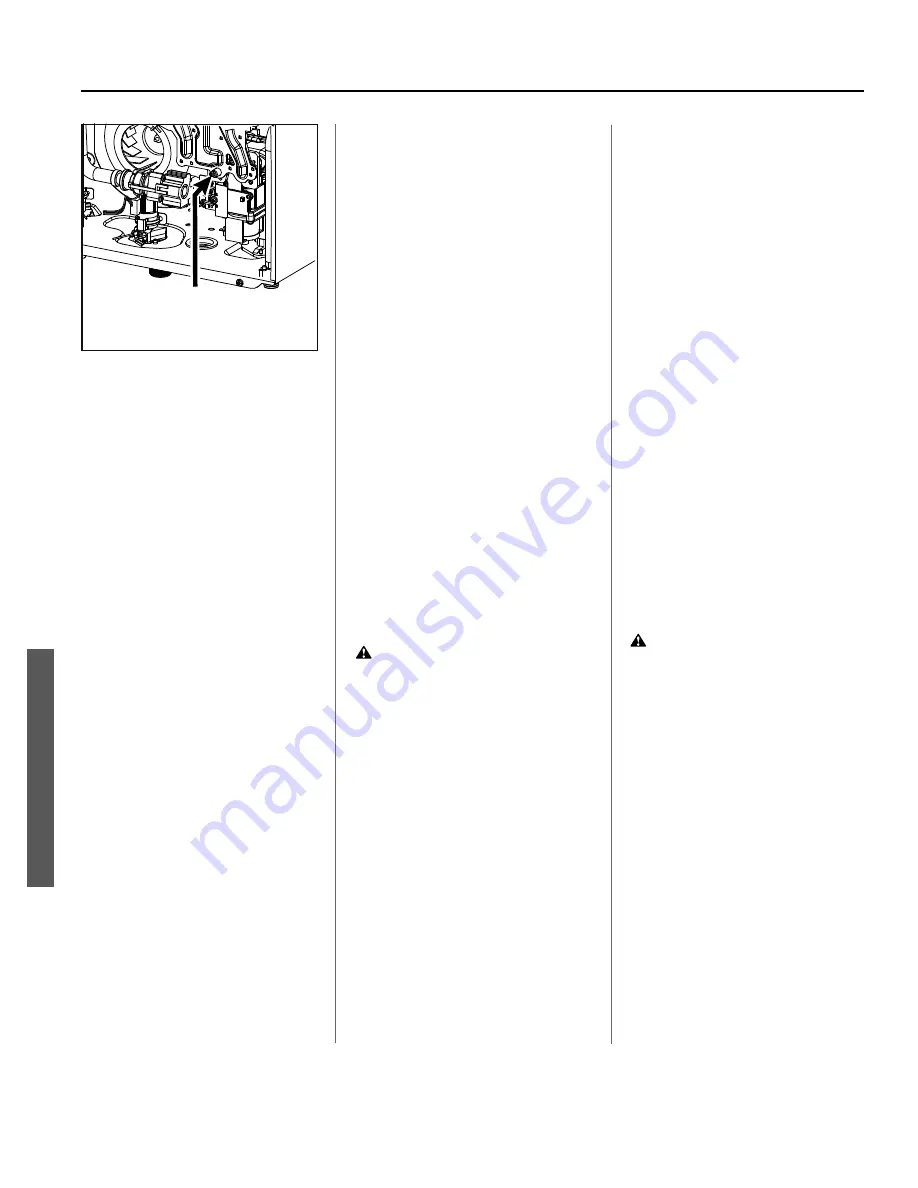

dŚĞƟƉŽĨƚŚĞĂƌƌŽǁŝŶĚŝĐĂƚĞƐ

ƚŚĞůŽĐĂƟŽŶŽĨƚŚĞŵĂŶŝĨŽůĚƉŽƌƚ͘

ZĞŵŽǀĞƐĐƌĞǁ͕ƚŚĞŶĂƩĂĐŚƚƵďĞ͘

Figure 14.