North American - ENG

Date Released:

10-20-20

3M-Matic

™

Accuglide V HSP - 2 Inch Taping Head - Type 12000

Page 10

44-0009-2157-5 / ECO#0086964

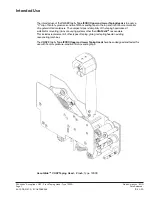

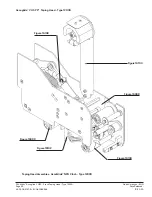

Figure 3-3

Tape Loading /

Threading

Figure 3-3

Insert threading needle through rollers in

direction indicated by arrows.

Operation

(continued)

It is recommended that the detailed

instructions and sketches in this manual

be referred to the first few times the

taping head is loaded/threaded until the

operator becomes thoroughly familiar

with the tape loading operation.

Note

–

Remove tape roll before removing

taping head from machine to

minimize

weight.

Tape Loading – Taping Head

1. Place the Taping Head in a

convenient

working

position.

2. Use

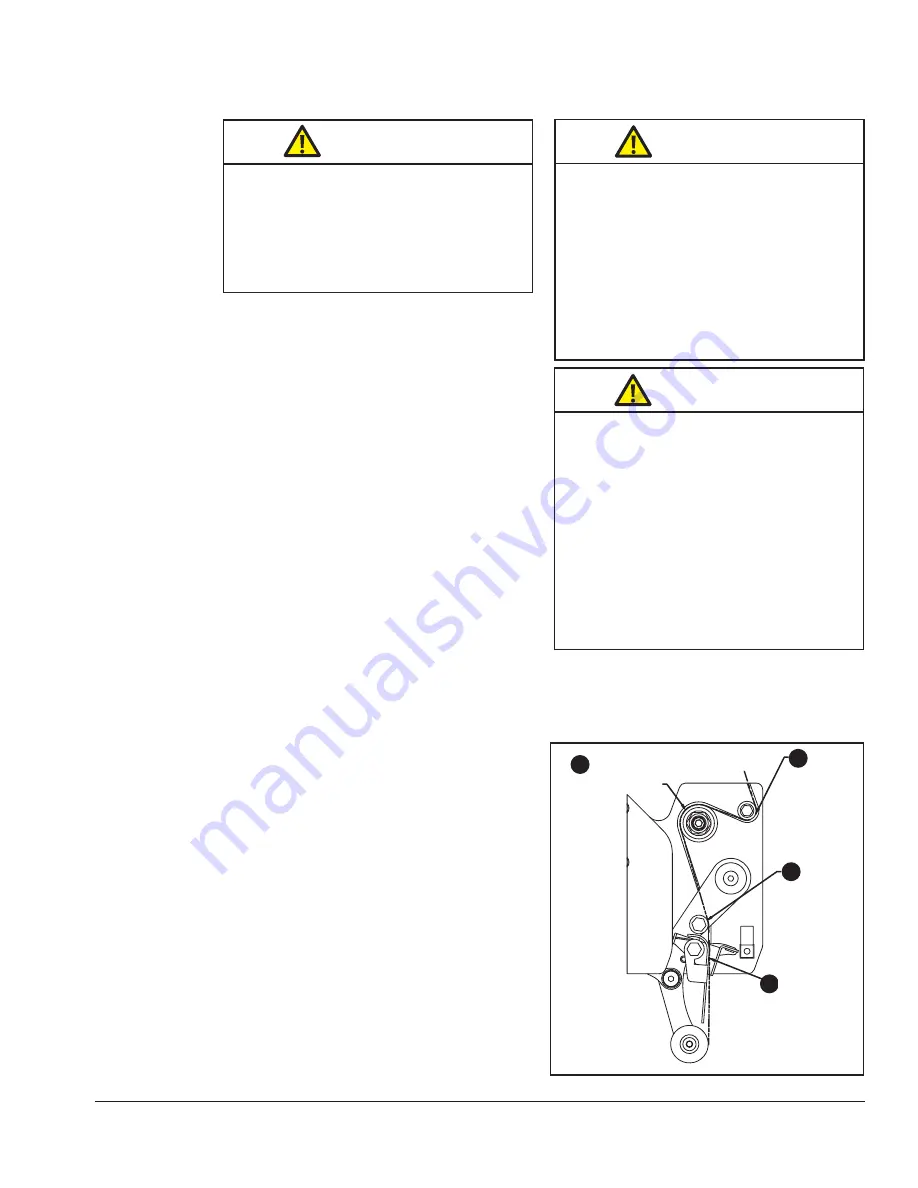

Figures 3-3/3-5

and tape thread-

ing label. Position tape roll so adhesive

side of tape faces front of taping head

as it’s pulled from supply roll.

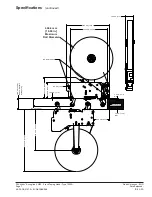

3. Guide the tape around the tension wrap

roller (Position 1) then back around the

one-way tension roller (Position 2).

4. Continue pulling the tape down and

past the wrap roller (Position 3) and

through the Tape Support Assembly.

5. Pull the tape down past the applying

roller (Position 4). When properly

threaded the adhesive side of the

tape should be facing the tension

roller at position 2 and away from

the guide roller at position 3.

6. Cut away any excess tape.

Important –

Do not cut against apply

roller - roller damage could occur.

Tape Loading – Lower Taping Head

1. Remove the lower taping head from

the conveyor bed or associated

equipment and place it a convenient

working

position.

2. Lower taping head is loaded and

threaded in same manner as upper head.

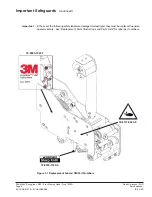

• To reduce the risk associated with

sharp blade hazards:

- Keep hands and fingers away from

tape cutoff blades under orange blade

guards. The blades are extremely sharp.

Warning

Caution

• To reduce the risk associated with

muscle strain:

-

Use proper body mechanics when

removing or installing taping heads

that are moderately heavy or may be

considered awkward to lift

• To reduce the risk associated with

impact hazards

-

Place the taping head on a smooth

level surface when maintaining or

servicing this equipment

• To reduce the risk associated with shear,

pinch, and entanglement hazards

- T

urn air and electrical supplies off

on associated equipment before

performing any adjustments, mainte-

nance, or servicing the taping heads

- Never attempt to work on the taping

head or load tape while the box drive

system is running

Warning

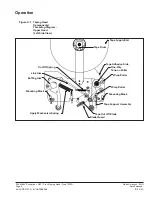

4.Tape Support Finger

One-Way

Tension Roller

1

2

3

4

Wrap Roller

Tension

Wrap

Roller

Tape

Support

Assembly

Summary of Contents for Accuglide V HSP

Page 46: ...38 ...