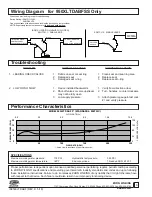

#3 TEST COCK

#4 TEST COCK

#2 SHUT-OFF

VALVE

LOW SIDE BLEED

NEEDLE VALVE

LOW SIDE HOSE

NOTE: BY-PASS OMITTED FOR CLARITY

(FOR BY-PASS TESTING REFER TO MAINTENANCE

INSTRUCTIONS FOR MODEL 350D)

#2 TEST COCK

#1 TEST COCK

(ON OPPOSITE

SIDE OF VALVE)

#1 SHUT-OFF

VALVE

HIGH SIDE BLEED

NEEDLE VALVE

HIGH SIDE HOSE

VENT HOSE

TEST NO. 2 - TIGHTNESS OF #2 CHECK VALVE

REQUIREMENT:

The static pressure drop across check valve #2 shall be at

least 1.0 psid. If test cock #4 is not at the highest point of

the check valve body, then a vertical tube must be installed

on test cock #4 so that it rises to the top of the check valve

body.

PROCEDURE:

1. Attach hose from the high side of the test kit to the #3

test cock.

2. Open test cock #3 and bleed all air from the hose

and gauge by opening the high side bleed needle

valve. Close high side bleed needle valve. If a tube is

attached to test cock #4, open test cock #4 to fill the

tube. Close test cock #4. Close #1 shut-off valve.

3. Hold gauge at same level as test cock #4 or water

level in tube. Slowly open test cock #4. Record the

static pressure drop across check valve #2 after

gauge reading stabilizes and water stops running out

of test cock #4.

4. Close all test cocks, slowly open shut-off valve #1 &

#2 and remove test equipment.

2

MODEL 950XLTDABF Double Check Detector Assembly

Testing Procedures

Equipment Required: Differential pressure gauge test kit.

TEST NO. 1 - TIGHTNESS OF #1 CHECK VALVE

REQUIREMENT:

The static pressure drop across check valve #1 shall be at

least 1.0 psid. If test cock #3 is not at the highest point of

the check valve body, then a vertical tube must be installed

on test cock #3 so that it rises to the top of the check valve

body.

PROCEDURE:

1. Slowly open all 4 test cocks to remove any foreign

material and attach fittings.

2. Attach hose from the high side of the test kit to the #2

test cock.

3. Open test cock #2 and bleed all air from the hose

and gauge by opening the high side bleed needle

valve. Close high side bleed needle valve. If a tube is

attached to test cock #3, open test cock #3 to fill the

tube. Close test cock #3. Close #2 shut-off valve then

close the #1 shut-off valve.

4. Hold gauge at same level as test cock #3 or water

level in tube. Slowly open test cock #3. Record the

static pressure drop across check valve #1 after

gauge reading stabilizes and water stops running out

of test cock #3.

5. Close all test cocks, open shut-off valve #1 and re-

move test equipment.

ZURN WILKINS

1747 Commerce Way, Paso Robles, CA 93446 Phone:

855-663-9876

Fax:805-238-5766

®

www.zurn.com