www.kraftool.hk

Band Saw

|

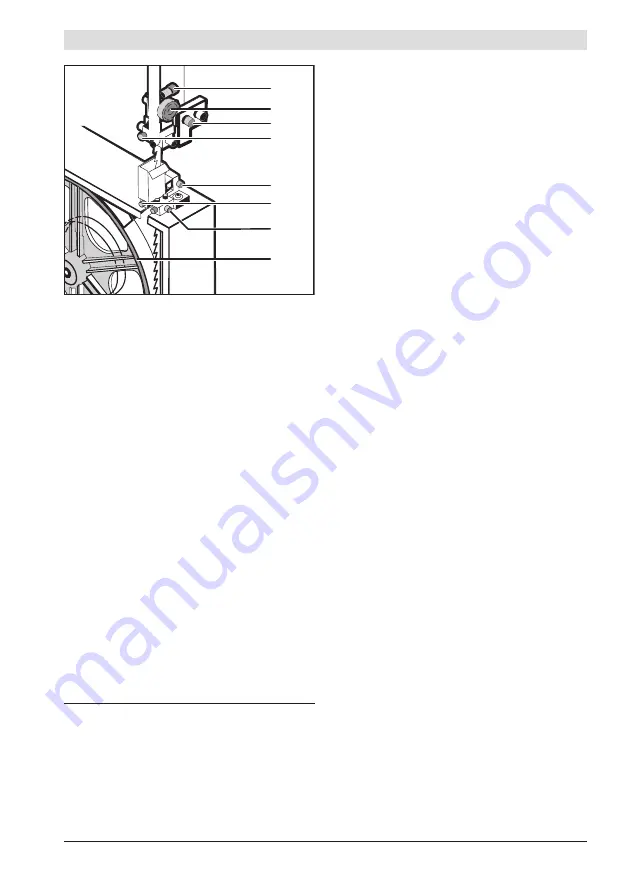

7

26

27

28

25

29

25

24

23

`

provide a safety detent of a blade by a bearing

27 in avoid of its disalignment under pressure of

the workpiece. To do this, rotate the adjusting

screw 26 and adjust the clearance between

the bearing and the rear edge of the blade is

equal to 0.7-1mm. Tighten the locking screw;

Note!

To prevent premature run-out of the bearing,

the bearing must not be pressed against the blade.

`

provide a limit of blade vibrations by releasing (use

a hex key) of fixing screws 25 and adjusting the

position of the pins 24 in the vicinity of the blade

(without its touching). Tighten the screws;

`

закройте крышку изделия и заверните винты

6

.

b) Adjustment of the lower limiter:

`

loosen the fixing screws 6 of the cover and open

it. Limiter is under work table;

`

provide a safety detent of a blade by a bearing

in avoid of its disalignment under pressure of the

workpiece. To do this, loosen the locking screw

29 and adjust the clearance between the bearing

and the blade is equal to 0.7-1mm. Tighten the

locking screw;

`

the setting of the lower limiter’s pins is similar

as for upper pins.

Getting Started

Check the tension of the blade. The properly

tensioned blade should NOT slip on the drive

wheels. If necessary, you can increase the tension

of the blade by rotating of the screw 4 clockwise.

Based on the workpiece and the nature of the

work:

а) Adjust the position of the upper limiter

5

:

`

loosen the screw of the regulator

10

;

`

adjust the position of the lowest point of the

limiter at a height of 2-3 sm from the top of

the workpiece by rotating of the fly screw (for

ZPL-305) or manually (for ZPL-350-190),

depending on the thickness of the workpiece;

`

tighten the screw of the regulator

10

.

b) Adjust the position of the longitudinal

guide

3

:

`

lift the locking handle 19 of the guide;

`

set the edge of guide according to the saw off width

of the workpiece;

`

lock the guide.

Note!

To avoid uneven cutting, as well as damage

(due to bending and twisting) of the saw blade,

always use the longitudinal guide when cutting.

c) If necessary an oblique cutting of workpiece, set

the angle detent at the desired angle.

d) If necessary to cut the workpiece with any angle

up to 45°, to set the angle of the table:

`

loosen the fixing of table tilt by the handle 11;

`

set the desired angle of cutting with a tilt pointer

of

the

table bracket 8;

`

lock the table tilt by the handle 11.

e)

Check the tension of the driving belt 22 (only

for

ZPL-305

). Well tensioned belt means that

when you press on it at the center between the

pulleys, the deflection should not exceed 1sm.

Otherwise, adjust the belt tension by the rotation

of the handle 30.

f)

Check (only for

ZPL-305

) an adjusted speed

of

blade. It should match to the workpiece material

and to the upcoming kind of the work. To do this:

`

remove the fastening screws 6 of the lower

cover and open the cover;

`

check the position of the belt 22 on the pulleys

and determine the current speed:

– the belt on a front pair of pulleys - higher

speed of movement of the blade;

– the belt on a rear pair of pulleys - lower speed

of movement of the blade.

If necessary, you can set the speed that you need: