12

Quick change system for SPRINT Series

Using a suitable spanner set the

absorving energy of the system with

which the tubular frame has to be

pushed in the guides on the centring

devices.

Fig. 20: Centring device, force setting

Check the setting by moving back and forth the cylinder arm frame holder

Change and check the settings of the absorving energy until you find the

appropriate setting.

Centring device

Impact

Setting tighter

higher effort

Setting looser

smaller effort

The setting is right if the cylinder arm frame holder slides into both clevises

evenly under slight pressure.

Slide the cylinder arm frame holder

with the centring devices in the guides

of the two clevises.

Set a

parallel

distance of 6,0 mm

±0,3 between the carriages of the

pantograph drive and the cylinder arm

frame holder.

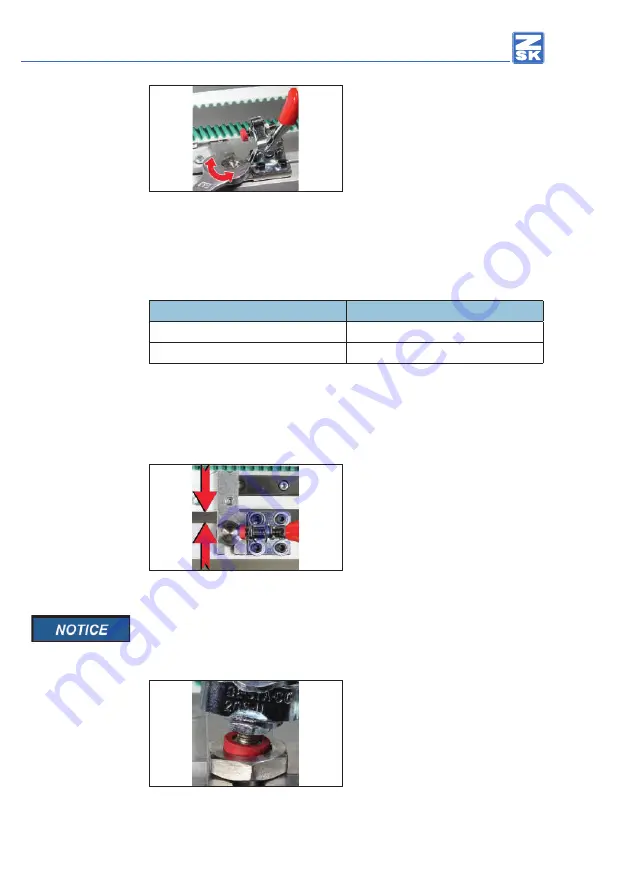

Fig. 21: Distance setting

To facilitate the setting of the 6 mm distance a correspondingly thick

gauge can be applied. This can be a metal strip, 2 screws or similar

material of the appropriate strength.

Place the clamping screws of the two

horizontal clamping fixtures centered

in the recording of centering devices.

Fig. 22: Clamping screw in the centring device

Содержание SPRINT Series

Страница 1: ...Quick change system SPRINT installation guide Made in Germany ZSK Stickmaschinen Made in Germany...

Страница 2: ......

Страница 22: ...22 Quick change system for SPRINT Series...

Страница 23: ...23 Quick change system for SPRINT Series...