•

Trouble shooting procedure

•

1

)

Adjust the number of parameter 25

•

2

)

Only in the pedal zero point adjustion testing function.it will cause this error.Adjust pedal positioning screw a bit.

•

3) Adjust pedal zero point position-procedure

:

•

1

、

install the pedal PCBA.The distance between steel magnet and PCBA should be controlled in

1.5mm~1.8mm,fixing PCBA.

•

2

、

Connect pedal, supply power by 80V isolation transformer, turn the steel magnet, make the output of sensor

voltage (voltage of C2) between 2.77~2.83V.

【

Note: When you adjust pedal, you must us 80V isolation

transformer supply power, the output of voltage is strong current .

】

•

3

、

Check the every positions of cutting to see whether it is normal

。

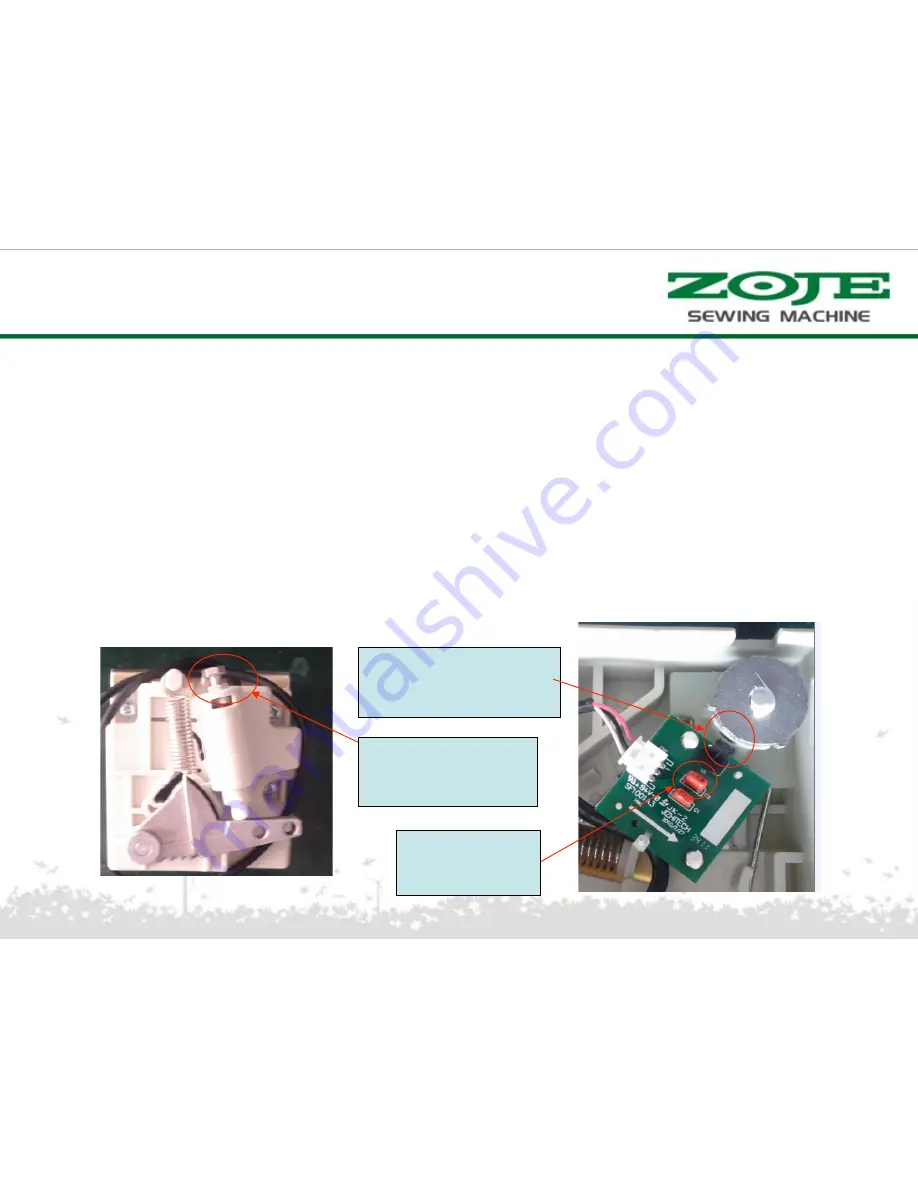

E15

(

Pedal zero point adjust error

:

zero point adjust over size

(

-1.5degree~1.5

)

Turn screw on pedal

in clockwise,

the angel became bigger,

conversely, smaller

Space between magnetic steel

and sensor of is 1.5mm~1.8mm

C2 ‘s voltage

is 2.77

~

2.83V

Error solution

Содержание WR580

Страница 1: ...WR580 PRODUCT MANUAL V1 0 ...

Страница 2: ...Application Model Code Hardware Structure Error Solution Catalogue ...

Страница 5: ...Composition of the product ...

Страница 9: ...Model description motor Motor model serial number ...

Страница 21: ...Function Aging mode Press to enter the aging mode Then press to start press again to stop ...

Страница 24: ...External interface definition power 1 2 3 4 Ground wire Power Socket definition L N ...

Страница 25: ...External interface definition pedal 5 1 6 4 Pedal Socket definition 3 2 PEDAL PGND 5V 2 For Factory use CN8 ...

Страница 26: ...1 4 3 2 Needle GND 5V 1 GND External interface definition Light Needle Pedal Socket definition ...

Страница 28: ...Main board PCBA appearance ...

Страница 29: ...Control box theory diagram ...

Страница 59: ...U37 TNY398 C38 IGBT Rectifier bridge 1 4 5 8 C3 D20 gative Black of muitimeter C5 C57 ERROR SOLUTION ...

Страница 60: ...谢 谢 ...