3

© Copyright 2020 Zoeller

®

Co. All rights reserved.

ELECTRICAL PRECAUTIONS-

Before servicing a pump, always shut off the main power breaker and then unplug the pump

- making sure you are wearing insulated protective sole shoes and not standing in water. Under flooded conditions, contact your local

electric company or a qualified licensed electrician for disconnecting electrical service prior to pump removal.

Submersible pumps contain oils which becomes pressurized and hot under operating condition.

Allow 2-1/2 hours after

disconnecting before attempting service.

If the above checklist does not uncover the problem, consult the factory - do not attempt to service or otherwise disassemble pump. Service must be performed by Zoeller

Authorized Service Centers. Go to www.zoellerpumps.com/service stations to find the Authorized Service Centers in your area.

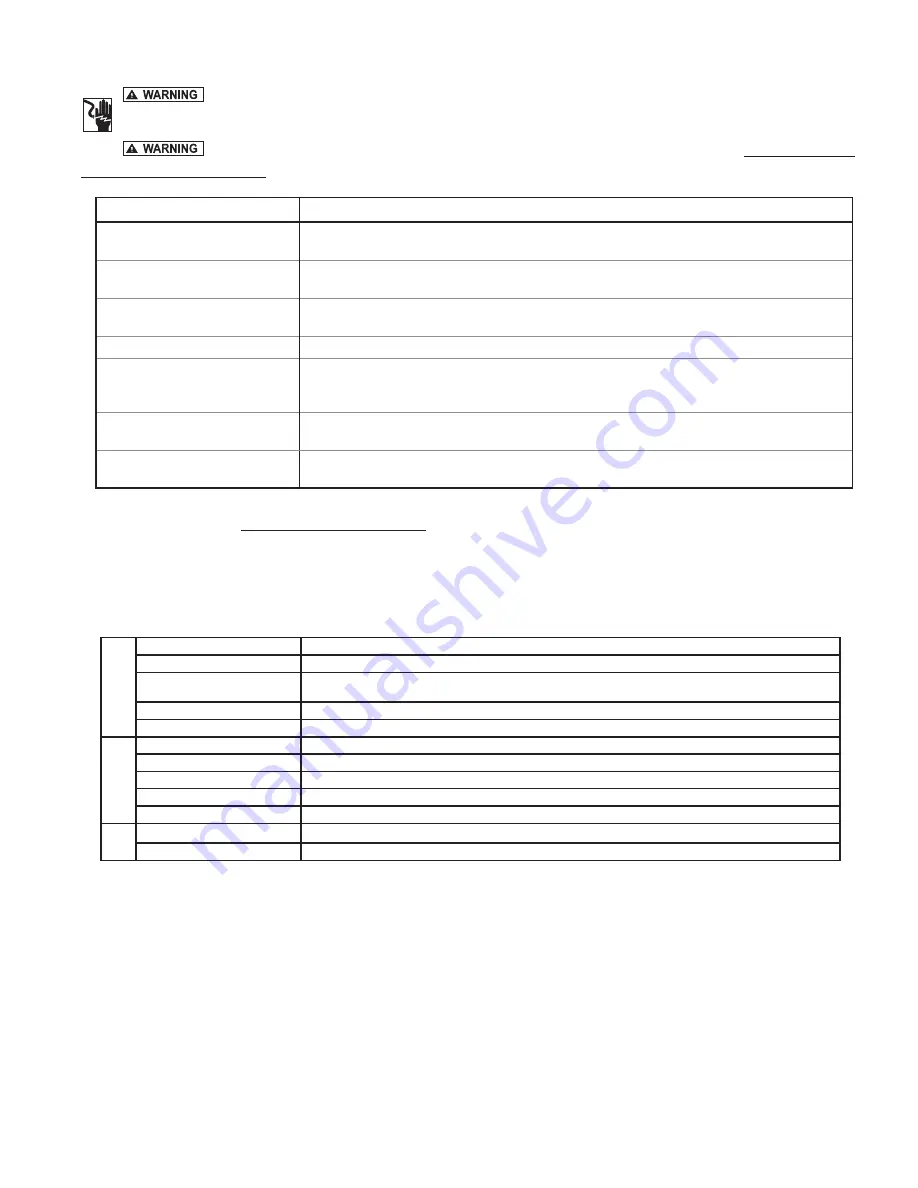

SERVICE CHECKLIST

CONDITION

COMMON CAUSES

A. Pump will not start or run.

Check fuse, low voltage, overload open, open or incorrect wiring, open switch, impeller or seal bound mechanically.

Motor or wiring shorted. Float assembly held down. Switch, damaged or out of adjustment.

B. Motor overheats and trips

overload or blows fuse.

Incorrect voltage, negative head (discharge open lower than normal) impeller or seal bound mechanically, motor

shorted.

C. Pump starts and stops too

often.

Float switch tether length too short, check valve stuck open, or none installed in long distance line, overload open,

bidding, sump pit too small.

D. Pump will not shut off.

Debris under float assembly, float bound by basin sides or other, switch damaged or out of adjustment.

E. Pump operates but delivers

little or no water.

Check inlet, strainer housing, discharge pipe, and vent holes for obstructions. Discharge head exceeds pump

capacity. Low or incorrect voltage. Incoming water containing air or causing air to enter pumping chamber.

Incorrect motor rotation. (DC pump only)

F. Drop in head and/or capacity

after a period of use.

Increased pipe friction, clogged line or check valve. Abrasive material and adverse chemicals could possibly

deteriorate impeller and pump housing. Check line. Remove base and inspect.

G.

If tank or fittings leak.

Carefully tighten pipe joints (use pipe dope) and screws. Check gasket location, tighten lid evenly. Do not over

tighten fittings or screws.

This system is a backup to your primary sump pump. It is designed to provide flood prevention during power outages or primary pump failure. This

system is unique in that it has self-testing.

DESCRIPTION

Pump

Construction

Non-corrodible plastic, premium seals

Performance

35 GPM at 10' (113 LPM at 3 m) at 12.7 volts

Continuous Running Time with 100

AH battery

5 hours

Duty Cycle of 10%

2 days

Connection

9' (2.7 m) wire with 2 position connector

Controller

Construction

ABS plastic

Power Requirement

115 V 15 amp circuit

Consumption

Up to 3 amps at 115 V

Charger Output

7 amp multi-stage

Connections

8' (2.4 m) AC power cord, 6' (1.8 m) DC charging cable, connections for pump, operation switch, high water switch

Battery

Box

Construction

Non-corrodible plastic

Safety

Snap tight lid, keeps battery safe and clean