BG1000 Series Barrier Gate

User Manual

P a g e

| 21

Copyright©2020 ZKTECO CO., LTD. All rights reserved.

barrier is activated.

Remote learning

function

000 - Learning State

253 - Automatic deletion

of the remote control

L-F

0

0

0

Deceleration stroke

adjustment for the first

section of the opening

gate

Default

L-H

0

0

0

Deceleration stroke

adjustment of the

second section of the

closing gat

Default

L-P

21

21

21

Traffic Light Mode

Adjustment

Default

L18

0

0

0

Ground Sensing Delay

to drop the boom

0 - Disabled

1 - 255 is the time

corresponding to the

delay

(need to synchronize

with the ground sensing

system)

L19

0

0

0

Automatic boom-

dropping delay after

starting

0 – Disabled

1 - 255 is the time

corresponding to the

delay in automatic

boom-dropping

L20

0

0

0

Remote Control Pairing and Unpairing

8.3

1.

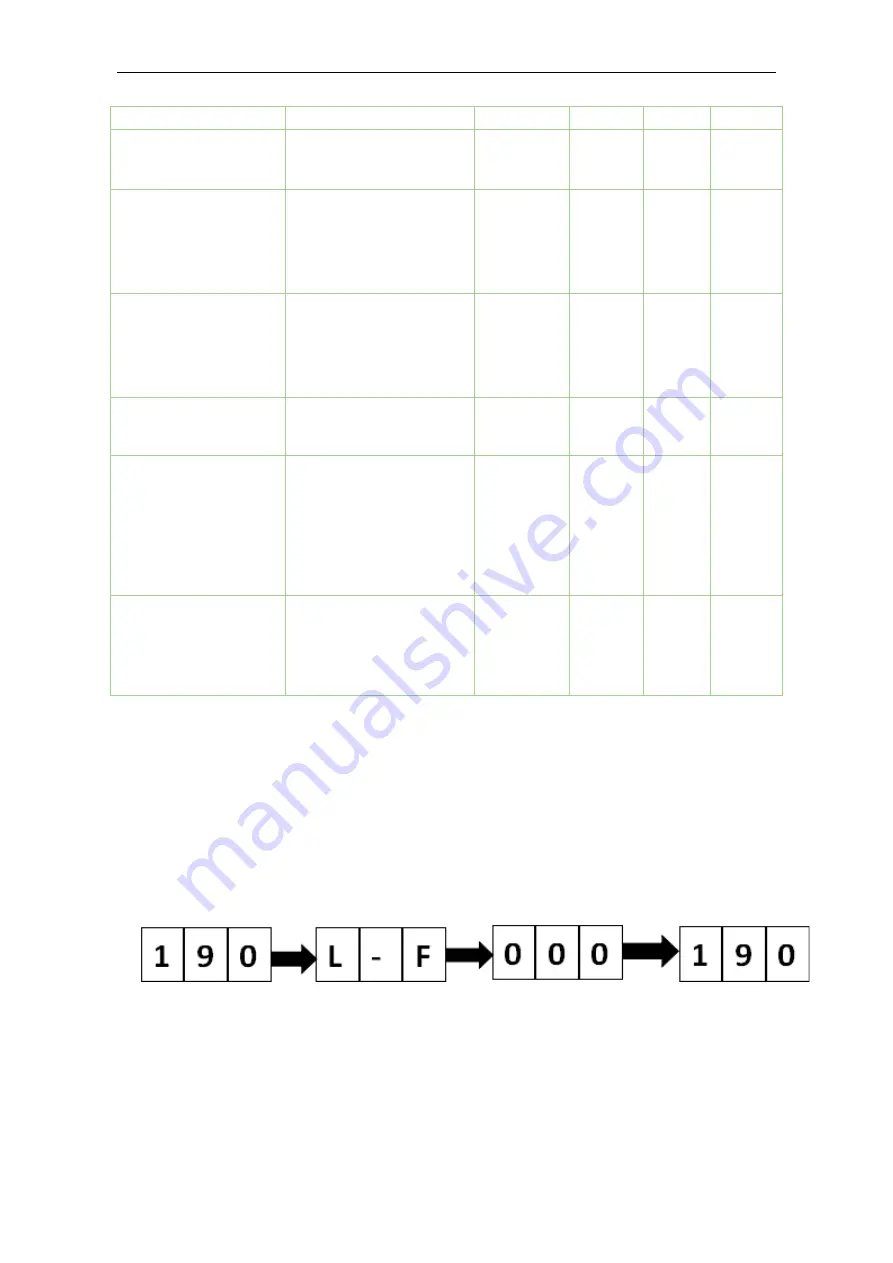

Remote Control Pairing:

Long press

Menu

, then press +/- to select L-F [L15]. Press

Menu

again to set the parameter value. At this time, the LED display value is "000",

and then press any button on the remote control until you hear a beep sound from

the Mainboard. If it automatically returns to the menu option, it means the pairing

is successful, and then press

Enter

to exit the menu.

2.

Delete Remote Control Pairing:

Long press

Menu

, then press +/- to select L-F

[L15]. Press

Menu

again to set the parameter value, and then set the parameter

value to "253". At this time, it will automatically return to the menu, indicating that

all the remote controls have been deleted.