18

2.5.1

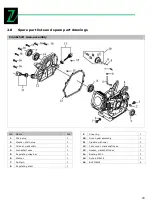

Fitting the vibration tube (Fig. C,

D)

Pull the cotter pin

3

out of the fitting

4

. Put

the tube

5

into the fitting and secure it with

the cotter pin.

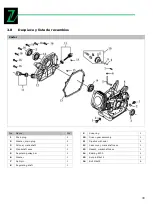

2.5.2

Starting (Fig. E, F, G)

Cold start:

Turn the ignition

11

to the position

ON.

Turn the throttle control

6

to idling

mixture (direction right).

Open the petrol cock

8

(right position).

Turn on the choker

7

(left position).

Now pull at the cable control power-

fully. If the machine doesn’t start

you’ll have to accelerate a bit.

When you have accelerated and the

engine runs you have to set idling mix-

ture again.

Turn off the choker (right position).

Let the engine run about 3 minutes

before beginning to work.

Set the required speed and begin to

work.

Warm start:

Let the choker turned off.

You have to do the other steps like the

steps of the cold start.

2.5.3

Stopping

Turn back the throttle control to idling

mixture.

Switch off the ignition.

Turn off the petrol cock.

Wait till the machine stands still for de-

positing the tube.

Before storing you have to wait till the

machine gets cold.

2.5.4

Placement of the machine (Fig.

H)

Place the machine on a flat ground.

Pull the lock bolt

12

upwards.

Turn the machine a bit so that you can

release the bolt without locking the ma-

chine again.

Before transporting the machine the next

time, it must be locked again.

2.6

Maintenance

A T T E N T I O N –

D A N G E R !

No cleaning, upkeep, checks or

maintenance when machine is run-

ning

Be safe: Shut off the machine, let it cool

down, disconnect spark plug cap from

spark plug.

The machine does not require intense mainte-

nance. However, to ensure a long lifespan, we

strongly recommend following the upkeep and

maintenance plan.

Repairs must be carried out by specialists! Use

original ZIPPER parts only!

2.6.1

Upkeep and maintenance plan

Controls for the maintenance of the machine

Loose or lost

screws, nuts, bolts

Regularly prior to

each operation

Damage of any part

of the machine

Regularly prior to

each operation

Controlling the oil

level

Regularly prior to

each operation

Machine cleaning

Regularly after op-

eration

Clean spark plug

Every 25 working

hours

Clean air filter

Every 20-30 work-

ing hours

2.6.2

Refuelling

The machine is run by unleaded petrol.

Ensure yourself that no particles get into

the fuel tank when refuelling, so always

use the filter that is under the tank cover

9.

Use unleaded petrol because it is better for

the environment than leaded ones.