TROUBLESHOOTING

ZIPPER MASCHINEN GmbH www.Zipper-Maschinen.at

29

ZI-RMM94H

29

Before disconnect the machine from the power supply and disconnect the air supply. Turn off the

compressed air supply and release by the filling the remaining pressure from the system before

disconnecting the machine at (24) from the compressed air supply.

Disposal

Observe the national waste disposal regulations. Never dispose of the

machine, machine components or equipment in residual waste. If necessary,

contact your local authorities for information on the disposal options

available. If you buy a new machine or an equivalent device from your

specialist retailer, he is obliged in certain countries to dispose of your old

machine properly.

17

Troubleshooting

W A R N I N G

Handling the machine with the power supply up can lead to serious injuries or even

death. Always disconnect the machine from the power supply before servicing or

maintenance work and secure it against unintentional or unauthorised reconnection!

Many possible sources of error can be excluded in advance if the machine is properly connected

to the mains. If you are unable to carry out necessary repairs properly and/or do not have the

required training, always consult a specialist to correct the problem!

Trouble

Possible cause

Solution

Machine does not start

Emergency stop

switch

to

switch off

switch

or

a phase

is broken

Overload protection is

triggered

.

Safety

fuse is blown

Open cover plate for saw

blades

Turn the

emergency

OFF

switch

to the right

to

unlock

to

Repair the

defective

circuit

or

the faulty

phase

Wait

until the engine

cools

down

Replace the

fuse

Cover plate close

Burn marks on the workpiece

The blade is blunt

Replace the blade

Fence values different from

the set value

Ruler incorrectly set

Adjust the ruler correctly

The

finished size

of the

machined workpiece

is

incorrect for the

cutting width

on rip fence

Adjusted

measurement scale

for the

cutting width display

Setting

dimension scale

:

cut

workpiece

on the rip fence

,

measure

the workpiece and the

measuring scale

move

so

that

the measured

average

width is

shown

at the

edge of the ruler

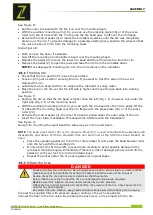

Sliding table

at

end positions

higher than

machine table

Lower rollers set incorrectly

Adjust

the lower rollers

Workpiece

clamped

while

advancing

dull

blade

Riving knife thickness does not

match the used blade

Replace

with

sharp

blade

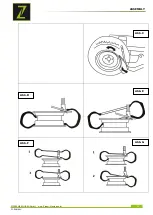

Splitting wedge

thickness

must

be greater than

or

equal to

blade

thickness

.

Broken

edges on the

workpiece

The

scoring saw

is not

on the

same line

with the

main saw

Set the

scoring saw

a

new

Arm

running not smoothly

Telescopic tube

or track

rollers

dirty

telescopic tube

or track

rollers

clean

Check

wipers

Содержание ZI-RMM94H 230V

Страница 14: ...BETRIEB ZIPPER MASCHINEN GmbH www Zipper Maschinen at 14 ZI RMM94H14 Abb C Abb D Abb E Abb F Abb G...

Страница 25: ...ASSEMBLY ZIPPER MASCHINEN GmbH www Zipper Maschinen at 25 ZI RMM94H25 Abb C Abb D Abb E Abb F Abb G...

Страница 34: ...ASSEMBLAGE ZIPPER MASCHINEN GmbH www Zipper Maschinen at 34 ZI RMM94H34 Abb B Abb C Abb D Abb E Abb F Abb G...

Страница 43: ...MONTAGGIO ZIPPER MASCHINEN GmbH www Zipper Maschinen at 43 ZI RMM94H43 Fig B Fig C Fig D Fig E Fig F Fig G...

Страница 52: ...ERSATZTEILE SPARE PARTS ZIPPER MASCHINEN GmbH www Zipper Maschinen at 52 ZI RMM94H52...

Страница 53: ...ERSATZTEILE SPARE PARTS ZIPPER MASCHINEN GmbH www Zipper Maschinen at 53 ZI RMM94H53...

Страница 62: ...PRODUKTBEOBACHTUNG PRODUCT MONITORING ZIPPER MASCHINEN GmbH www Zipper Maschinen at 62 ZI RMM94H62...