801910 v3.05 09.20 HT BCS Commercial Instructions

Page 3 of 32

HydroTap Specifications

Installation check list ....................................................................................................................4

Important Safety Instructions .......................................................................................................5

Warnings and Regulatory Information ..........................................................................................6

Major Components and Accessories ...........................................................................................7

Technical Specifications ...............................................................................................................8

Before Installation and Site Requirements ...................................................................................9

Installation Instructions

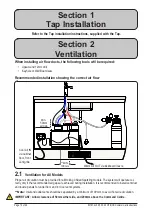

STEP 1 -

Measure and cut all the tap holes before fitting the taps

(Refer to the Tap installation instructions, supplied with the Tap)

STEP 2 -

Check for adequate ventilation

Section 2 - Ventilation

2.1 - Ventilation for All Models ..........................................................................................10

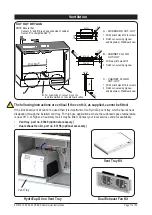

STEP 3

- Install the Command Centre

Section 3 - Command Centre installation

3.1 - Check the external bypass valve setting ...................................................................12

3.2 - Hose and tube fitting .................................................................................................12

3.3 - John Guest fittings ....................................................................................................13

3.4 - Carbonation valve .....................................................................................................13

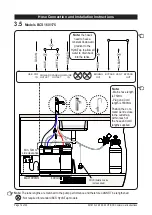

3.5 - Model BCS 160/175 ..................................................................................................14

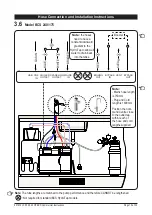

3.6 - Model BCS 240/175 ..................................................................................................15

3.7 - Model AIO Mains 160/175 ........................................................................................16

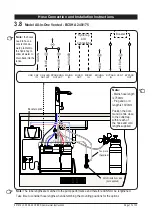

3.8 - Model AIO Vented 240/175 .......................................................................................17

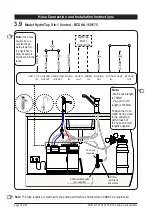

3.9 - Model 5-In-1 Vented 160/175 ...................................................................................18

3.10 - Model 5-In-1 with Booster 240/175 .........................................................................19

STEP 4

- Install the Booster Heater (if required)

Section 4 - Booster heater Installation

4.1 - 4.4 - Booster Heater specifications and installation ..................................................20-22

STEP 5

- Mount the external filter / softener (if required)

Section 4- Filter / Softener installation

5.1- 5.2 - Mounting the filter head & cartridge installation .................................................23

STEP 6 -

Fit the CO

2

Gas cylinder

Section 5 - CO

2

Cylinder and Regulator

6.1 - 6.5 - Connect, secure and test the CO

2

gas cylinder ................................................24

STEP 7

- Commission the HydroTap

Section 7 - Commissioning

7.1- CO

2

Purge .................................................................................................................26

7.2- Filter Flush .................................................................................................................26

7.3- Boiling Calibration ......................................................................................................27

7.4- Booster .......................................................................................................................27

7.5- Safety Sensor Calibration ..........................................................................................28

7.6- Command-Centre Flush .............................................................................................29

7.7- Carbonation Valve Flow Adjustment ..........................................................................29

Troubleshooting ...........................................................................................................................30

End of Life Disposal .....................................................................................................................31

Contact Details .............................................................................................................................32

Index