17

805812 v1.04 05.20 HydroChill Install Instructions

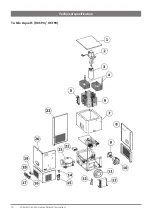

Step 2 – Install Chiller

2.1 Positioning

The chiller must be placed in a hygienically suitable environment, on

a surface capable of bearing the weight of the machine complete with

water. Do not place close to direct or indirect heat sources (ovens,

stoves, radiators, etc.).

Locate close to electricity and water supply points. Ensure the

power cable and water hose do not form an obstruction. The water

connections and condenser need to be accessible for maintenance.

Protect from water splashes and place in a location with the

temperature appropriate to the climate class stated on the EC

nameplate, otherwise malfunctions may occur and warranty rights are

forfeited.

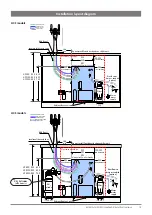

2.2 Ventilation

Allow a minimum clearance of 200mm around the back, top and

sides of the chiller unit.

For installation in an enclosed single cupboard, the vent kit and a

double auxiliary fan kit (part no 93159) must be installed.

• Install the kickboard vent grille for external air intake.

• Install the fan at the top of the cupboard to extract hot air out of

the cupboard (requires additional electrical power outlet).

• Cut-out in the cabinet floor.

For installation in an enclosed, double cupboard, the minimum

ventilation requirement is:

• Perforated or expanded metal door with at least 60% open area

• 2x cut-outs in the cabinet floor to provide air intake.

If ventilation is insufficient, additional vents and fans may be installed

as optional extras. Contact Zip service for details.

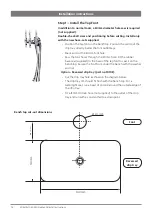

2.3 Overflow connection

Check the overflow connector is not obstructed. Use a tube to

connect the overflow drainage connector (A) from the tank to a

drainage point or a large container (not supplied).

A tundish to comply with AS3500 may be required if the unit is

installed in a cupboard, or in an area not utilising a floor waste.

Installation instructions

EC climate classes:

SN - For ambient temperatures from 10°C to 32°C

N - For ambient temperatures from 16°C to 32°C

ST - For ambient temperatures from 18°C to 38°C

T - For ambient temperatures from 18°C to 43°C

100- 200

mm

200

mm

100-200

mm

200

mm

200

mm