OWNER’S MANUAL - 5 - YF-48N A/0

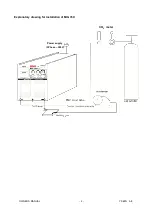

INSTALLATION INSTRUCTION

1

)

Connect the main circuit cable of the wire feeder to the corresponding output end of the machine, and fasten with

bolts.

2

)

Connect the plug of the control circuit 6-core cable of the wire feeder to the corresponding interface of the machine

and lock.

3

)

Connect the lug of earth wire to the corresponding output end of the machine, and fasten with bolts.

4

)

Install the CO

2

gas meter on the gas cylinder, connect the trachea of the wire feeder to the CO

2

gas meter tightly.

5

)

Plug the welding gun to the welding gun output socket of the wire feeder and rotate 45°clockwise. Tighten the welding

gun fastening screws with in turn spanner so as that the welding gun contacts with the wire feeder output socket

reliably. Connect the controller plug and the gas connection to the wire feeder.

6

)

Install the wire reel loaded with welding wire on the shaft bracket of the wire feeder, select different wire feeding

groove according to the welding wire diameter.

7

)

Loosen the pressure arm, feed the welding wire into wire feeding pipe through gadget wheel and groove. Press the

pressure arm so that the wire pressing wheel presses the welding wire tightly to prevent the welding wire from sliding.

Do not push the pressure arm too hard, prevent the welding wire from deformation and interfering with wire feeding.

The welding wire roll rotates clockwise to loosen the welding wire. In order to prevent the leading end of wire reel from

loosening, it is generally fixed to the fixing hole of the wire reel. Cut off this part of welding wire to prevent the winding

welding wire from getting struck during normal operation.

8

)

This procedure shall be operated by electrician!

Connect proper power cord to the distribution box with corresponding capacity according to the input voltage and

current of the welding machine (See technical parameter table). Do not connect to the inappropriate voltage and

make sure that the difference of power supply is within permitted range.

Содержание MIG-350

Страница 1: ......

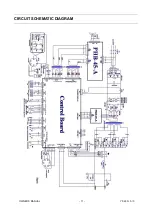

Страница 12: ...OWNER S MANUAL 11 YF 48N A 0 CIRCUIT SCHEMATIC DIAGRAM...