The PTO does shall not rotate when one of the two switches is in the OFF position

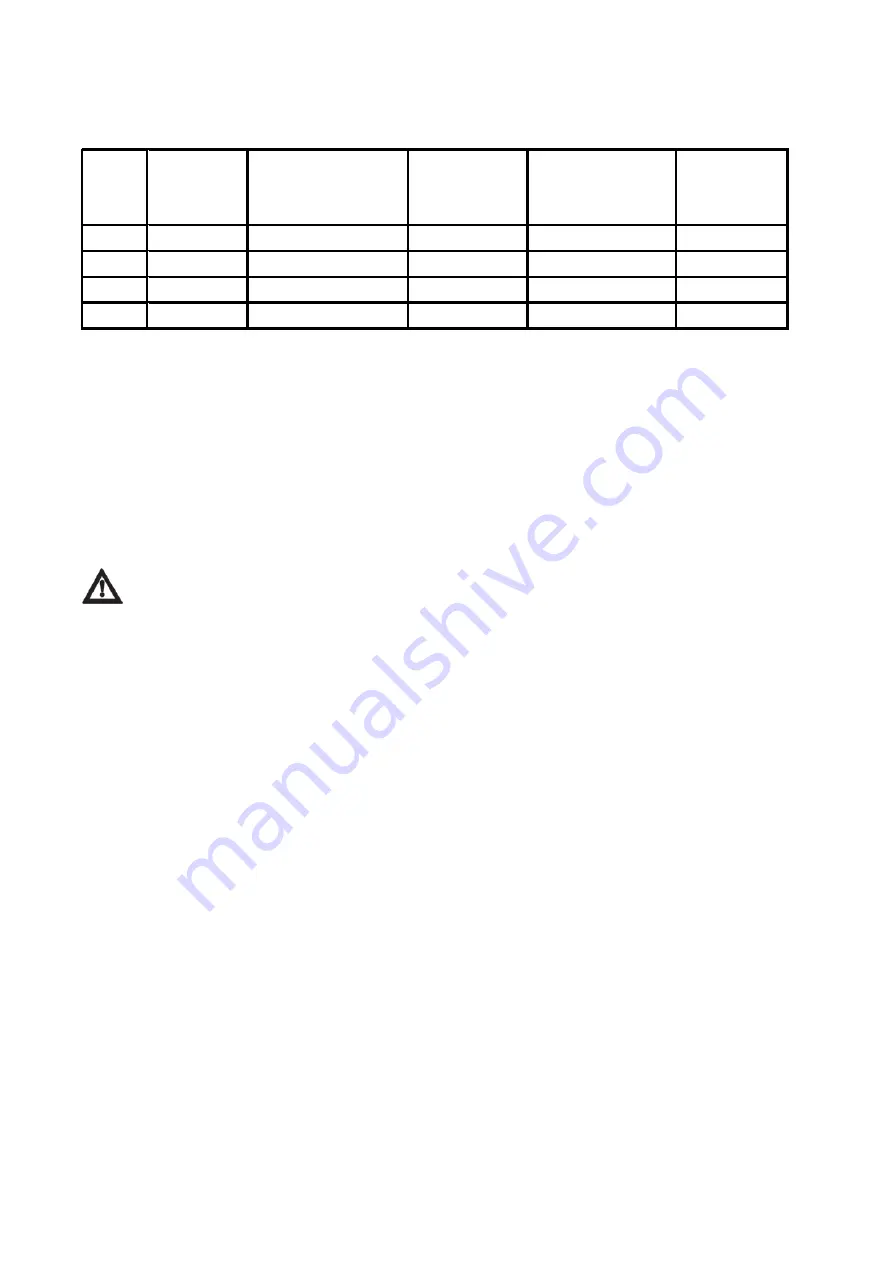

The following table explains how the PTO operates in two different positions (Manual & Auto) of the PTO

control switch with the PTO ON / OFF switch in the ON position.

The table above shows the PTO safety features. When the indicator light on the dashboard flashes, it

indicates to the operator that the PTO is in the 'ON' position, but does not temporarily rotate either

because the clutch pedal is depressed or because the implement is lifted off the ground, or both. The

PTO starts to rotate immediately when the clutch pedal is released and / or the implement is lowered

to the working position.

The operator must ensure that there are no persons in the operating area of the tractor due to

possible bouncing of objects or particles from the rotating working parts of the implement and the

intervention and injuries of persons near the working unit.

Stopping the PTO, when lifting the implement from the ground together with a position check,

prevents damage to the implement or PTO.

Warning:

When the PTO control switch is in manual position the PTO does not stop rotating even if the

clutch pedal is pressed. If working on hard soils, pavements with a rotary implement the PTO

''ON/OFF'' switch must be put to the ''OFF'' position to stop the PTO from rotating , If this is not

done the rotating blades of the implement will push on the hard ground below and in turn push

the tractor toward causing accident which can lead to serious injuries or death.

Extra precaution must be taken to clear the area of bystanders/onlookers when using PTO

driven implements. The rotating blades of the implements can cause serious injuries on

contact. The warning that is indicated by the blinking PTO monitor is to make the operator

aware that the PTO is in on position and will instantly start rotating if the clutch pedal is

released or implement is lowered or both.

In no case the specified rotating speeds indicated by the implement manufacturer be crossed

as the same can lead to serious damage to the tractor/equipment and can lead to serious

injuries to persons around.

PTO

ON/OFF

Switch

PTO

Control

Switch

Clutch

Pedal

Hydraulic

Position

Control Lever

PTO Indicator Light

on the Instrument

Panel

PTO

ON

Manual mode Depressed or released Lifted or lowered On

Rotates

ON

Auto mode

Depressed

Lifted or lowered Flashes

Does not rotate

ON

Auto mode

Depressed or released Lifted

Flashes

Does not rotate

ON

Auto mode

Released

Lowered

On

Rotates

TRACTOR CONTROLS

46

Содержание UTILIX CL

Страница 1: ...OPERATOR S MANUAL UTILIX CL 01 2021 45 Tractor is Zetor Since 1946 55...

Страница 3: ...2...

Страница 9: ...NOTES 8...

Страница 11: ...NOTES 10...

Страница 39: ...NOTES 38...

Страница 119: ...NOTES 118...

Страница 125: ...NOTES 124...

Страница 131: ...NOTES 130...

Страница 134: ...133...

Страница 136: ...www zetor com zetor zetor com Made in EU...