PV154 - 923-03499

10

P50W26 - SERVICING

SERVICING

Va voltage

adjustment

variable resistor

VR4

VR1

DMM

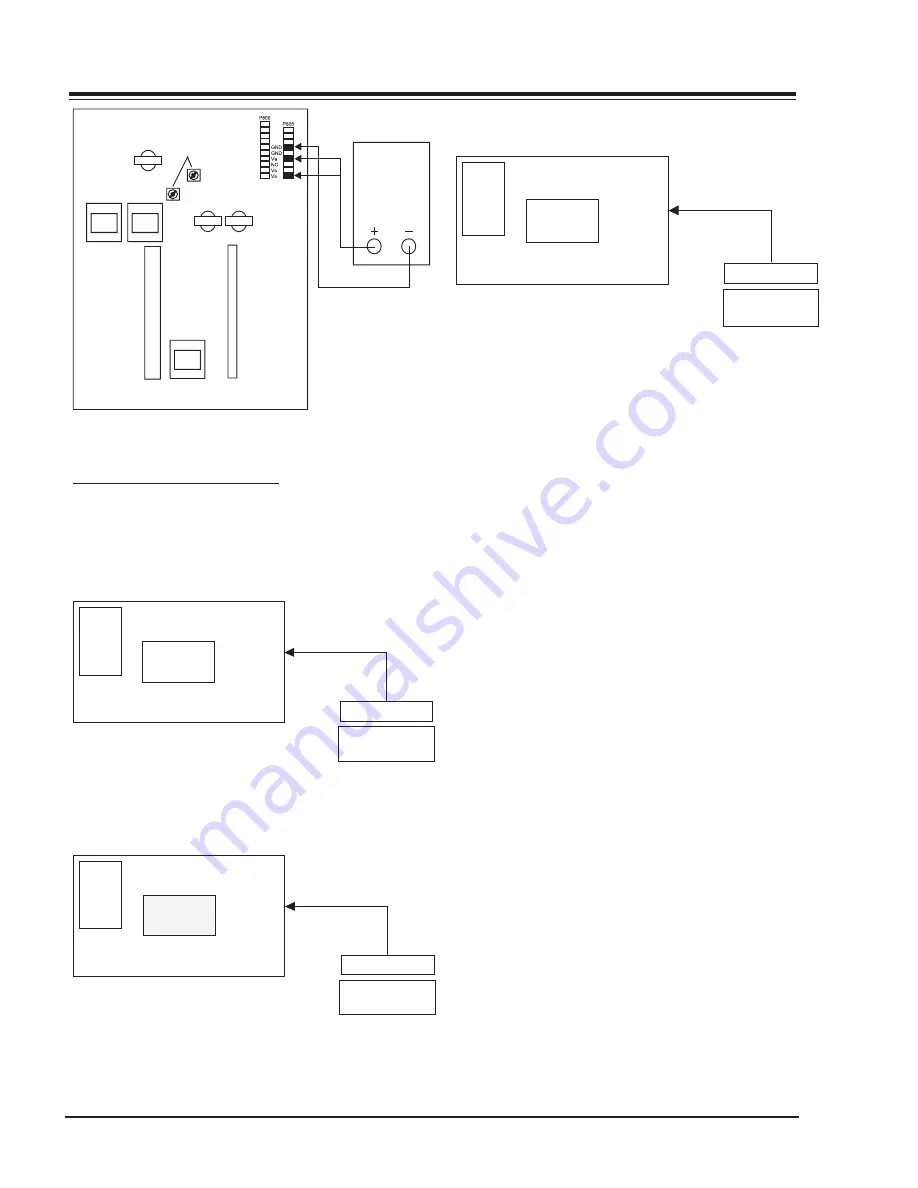

<Fig 1> Connection Diagram of Power Adjustment

ADJUSTMENT OF WHITE BALANCE

REQUIRED EQUIPMENT

Color analyzer (CA-100 or same product)

CONNECTION DIAGRAMS (MANUAL ADJUSTMENT)

High Light

216 Gray Level

135 140Cd/

RGB Signal Input

PDP MONITOR

§‡

R-L 70

G-L 70

R-M 128

G-M 128

R-H 216

G-H 216

COLOR

ANALYZER

CA-100

MSPG-2100 or

MSTG-5200

Window

<Fig 2> Connection Diagram of Manual

Adjustment(High Light)

Middle Light

128 Gray Level

70~75Cd/

RGB Signal Input

PDP MONITOR

§‡

R-L 70

G-L 70

R-M 128

G-M 128

R-H 216

G-H 216

COLOR

ANALYZER

CA-100

MSPG-2100 or

MSTG-5200

Window

Fig 3> Connection Diagram of Manual

Adjustment(Middle Light)

Low Light

70 Gray Level

20~25Cd/§‡

RGB Signal Input

PDP MONITOR

R-L 70

G-L 70

R-M 128

G-M 128

R-H 216

G-H 216

COLOR

ANALYZER

CA-100

MSPG-2100 or

MSTG-5200

Window

<Fig 4> Connection Diagram of Manual

Adjustment(Low Light)

ADJUSTMENT OF WHITE BALANCE

Operate the Zero-calibration of the CA-100, then stick

sensor to PDP module surface when you adjust. For

manual adjustment, it is also possible by the following

sequence.

1) Select WHITE PATTERN of HEAT RUN mode by press-

ing POWER ON KEY on remote control for adjust-

ment then operate HEAT RUN more than 15 minute.

2) Supply 216Gray, 128Gray, 70Gray Level, 50% size

length and breadth signal to RGB1 input. (Refer

to Fig 2,3,4)

3) W/B adjustment must be adjusted once and follow

the sequence of Low Light —> Middle Light —>

High Light and then save the adjustment value

with o Key.

4) To adjust Low Light, stick sensor to Gray Level(or

20~25 Cd/m2) Pattern, press ADJ Key on R/C for

adjustment and press v, x on R/C in adjustment

mode to select R-L or G-L, press VOL +, - Key and

adjust it until color coordination becomes as be-

low.

X: 0.290±0.003, Y: 0.300±0.003

Color temperature: 8, 500

o

K±500

o

K

5) To adjust Middle Light , stick sensor to Gray Level

(or 70~75 Cd/m2) Pattern, press ADJ Key on R/

C for adjustment and press v, x on R/C in adjust-

ment mode to select R-M or G-M, press VOL +, -

Key and adjust it until color coordination becomes

as below.

X: 0.290±0.003, Y: 0.300±0.003

Color temperature: 8, 500

o

K±500

o

K

6) To adjust High Light, stick sensor to Gray Level(or

135-140 Cd/m2) Pattern, press ADJ Key on the

R/C for adjustment and press v, x on R/C in ad-

justment mode to select R-L or G-L, press VOL +,

- Key and adjust it until color coordination be-

comes as below.

Содержание P50W26

Страница 4: ......

Страница 8: ......

Страница 21: ......

Страница 22: ......

Страница 25: ...29 P50W26 DIAGRAMS PV154 923 03499 P50W26 Block Diagram...

Страница 26: ...30 P50W26 DIAGRAMS PV154 923 03499 P50W26 Main PCB M A I N TOP...

Страница 28: ...32 P50W26 DIAGRAMS PV154 923 03499 P50W26 Other PCBs...