9

Inspection steps for components

The gripper (6) is not closing, and the safety cable can be pulled up:

X

Decommission the service lift immediately.

X

Attach a corresponding sign at the main switch of the service lift.

X

Inform the operator and manufacturer of the service lift.

X

Have the gripper (6) inspected and repaired by authorised and qualified specialist personnel.

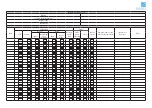

The inspections and results must be documented in the inspection record immediately after the inspection.

X

Tick the "Trigger" field after the inspection has been carried out.

X

If the inspection failed, tick the "Out of service" field.

X

Enter any special items of note in the "Notes" field.

8.3 Checking the brakes of the winch and centrifugal force weight of the gripper

DANGER!

Serious injury or death due to falling as a result of a non-functioning brake.

X

Press the EMERGENCY STOP button.

X

Disconnect the power supply to the winch via the main switch.

X

Decommission the service lift immediately.

X

Attach a corresponding sign at the main switch of the service lift.

X

Inform the operator and manufacturer of the service lift.

X

Have the winch and gripper examined and repaired by authorised and qualified specialist personnel.

DANGER!

Risk of serious injury from falling objects.

X

Do not remain under suspended loads.

X

Cordon off the area of danger.

Before each use of the service lift, ensure that

à

The centrifugal force weight (4) rotates during movement of the lift

à

The brake grips and holds the service lift on the suspension cable

For this purpose, carry out the following steps in order:

X

Visually inspect to ensure that the winch (7) is properly

secured to the service lift.

X

Ensure that the plug (5) is positioned correctly at the

motor.

X

Set the hand lever (1) to position A.

à

The gripper (6) is open.

X

Move the service lift up approx. 2 metres.

X

Look in the viewing window to ensure that the centrifu-

gal force weight (4) rotates during lift movement.

à

In general, the centrifugal force weight (4) must be

observed through the provided viewing window

during each movement of the lift.

2.

1.

1.