31

1. Close start or disconnect switch.

2. Replace fuse.

3. Refer to electrical section.

4. Repair or replace control.

5. Relocate control.

6. Check wiring against diagram.

7. Replace or relocate.

8. Trace control circuit with wiring dia-

gram and repair.

9. Replace the compressor with all pre-

cautions.

1. Line disconnect switch open.

2. Fuse removed or blown.

3. Overload protector tripped.

4. Control stuck in open position.

5. Control off due to cold location.

6. Wiring improper or loose.

7. Thermostat defective or improperly

installed.

8. Control circuit open.

9. Burned/open circuit motor winding.

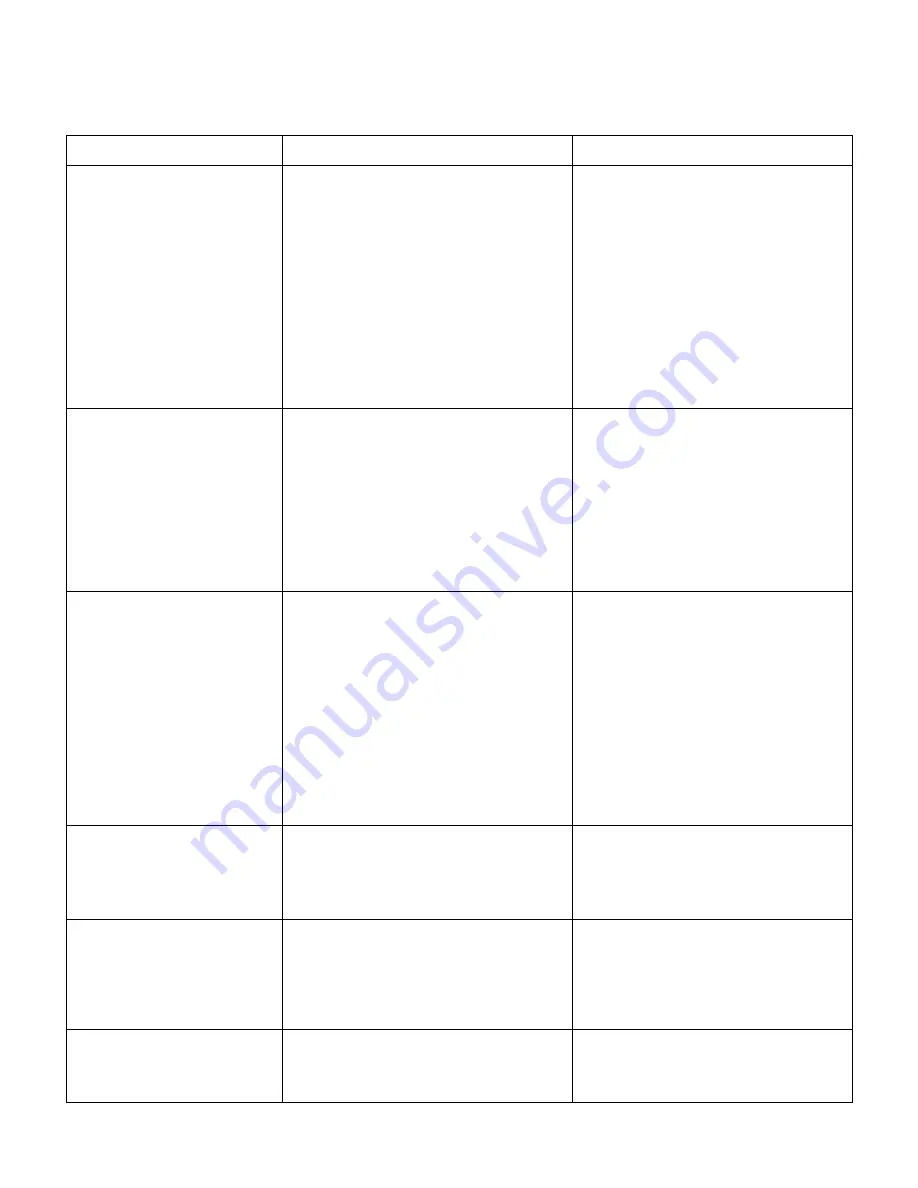

Compressor will not start – no

hum.

TROUBLE SHOOTING CHART

SYMPTOM

CAUSES

CHECK & CORRECTIVE MEASURE

1. Additional current passing through

overload protector.

2. Low voltage to unit (or unbalanced if

three phase).

3. Overload protector defective.

4. Excessive discharge pressure.

5. Suction pressure too high.

6. Compressor too hot - return gas hot.

1. Check wiring diagram. Check for

added fan motors, pumps, etc. con-

nected to wrong side of protector.

2. Determine the reason and correct.

3. Check current, replace protector.

4. Check airflow across the condenser

coil, restrictions in refrigeration system.

5. Check for possibility of misapplica-

tion. Use stronger unit.

6. Check refrigerant charge (fix leak),

add if necessary.

1. Check wiring against diagram.

2. Determine reason and correct.

3. Replace compressor.

4. Replace compressor.

5. Check crankcase heater.

6. Unequilized pressure in the system.

1. Improperly wired.

2. Low voltage to unit.

3. Compressor motor has a winding

open or shorted.

4. Internal mechanical trouble in com-

pressor.

5. Liquid refrigerant in compressor.

6. High discharge pressure.

Compressor starts and runs,

but short cycles on overload

protector.

Compressor will not start –

hums but trips on overload

protector.

Suction line frosted or sweating.

Liquid line frosted or sweating.

1. Expansion valve passing excess re-

frigerant or is oversized.

2. Expansion valve stuck open.

3. Evaporator fan not running.

4. Overcharge of refrigerant.

1. Restriction in dehydrator or strainer.

2. Liquid shut-off valve partially closed.

1. Re-adjust valve or replace with smaller valve.

2. Clean valve of foreign particles, re-

place if necessary.

3. Determine reason and correct.

4. Correct charge.

1. Replace part.

2. Open valve fully.

Space temperature too high.

1. Control setting too high.

2. Expansion valve too small.

3. Cooling coils too small.

4. Inadequate air circulation.

1. Reset control.

2. Use larger valve.

3. Add surface or replace.

4. Improve air movement.