OT2115

Driver

13

4.8 adjustment

Actuator stroke

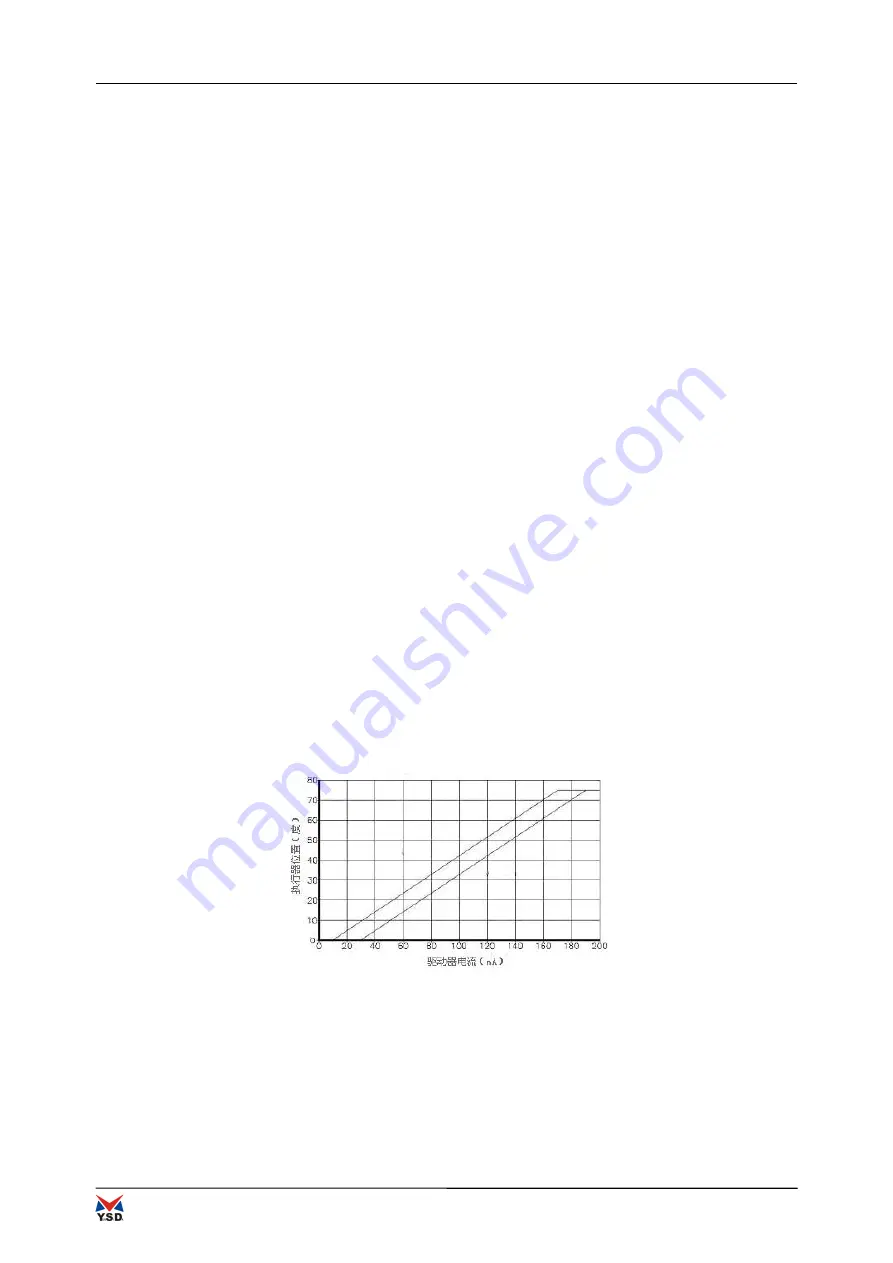

In general, there is no need to adjust the span (SPAN) and offset (OFFSET) of the drive circuit

board, unless the actuator is unable to run the full range of difficulties. Figure 3-7 defines

the relationship between the position of the actuator and the input position signal (0 ~ 200mA).

If the curve not within the error limits and need by adjusting the span and offset will be

adjusted to limit deviations range between. If you want to adjust the actuator, you should

first disconnect the connection between the motor and the linkage device, and then add power

to the actuator. At this point, do not start the engine.

Change the input current of the drive and observe the actuator rotation angle.

Adjust the span and offset potentiometer to achieve the desired relationship, see

figure 3-7. Inappropriate adjustments may result in failure to shut off the supply

or fail to achieve adequate fuel supply. After adjustment, re connect the linkage

device.

Whenever a change is made to the installation or drive settings of the actuator,

the stroke of the actuator should be re adjusted. For a given input signal to the

driver, a clockwise rotation of the two potentiometer will increase the position

of the actuator output.

Actuator position feedback sensor for factory default settings, without

adjustment.

Figure 3-7 drive set deviation limit

5、Common troubleshooting guide

When the governor matching the normal operation of the engine, if the subsequent speed instability

occurs, the majority of the engine or load reasons, rather than the governor. This speed change will lead to the