OT2115

Driver

8

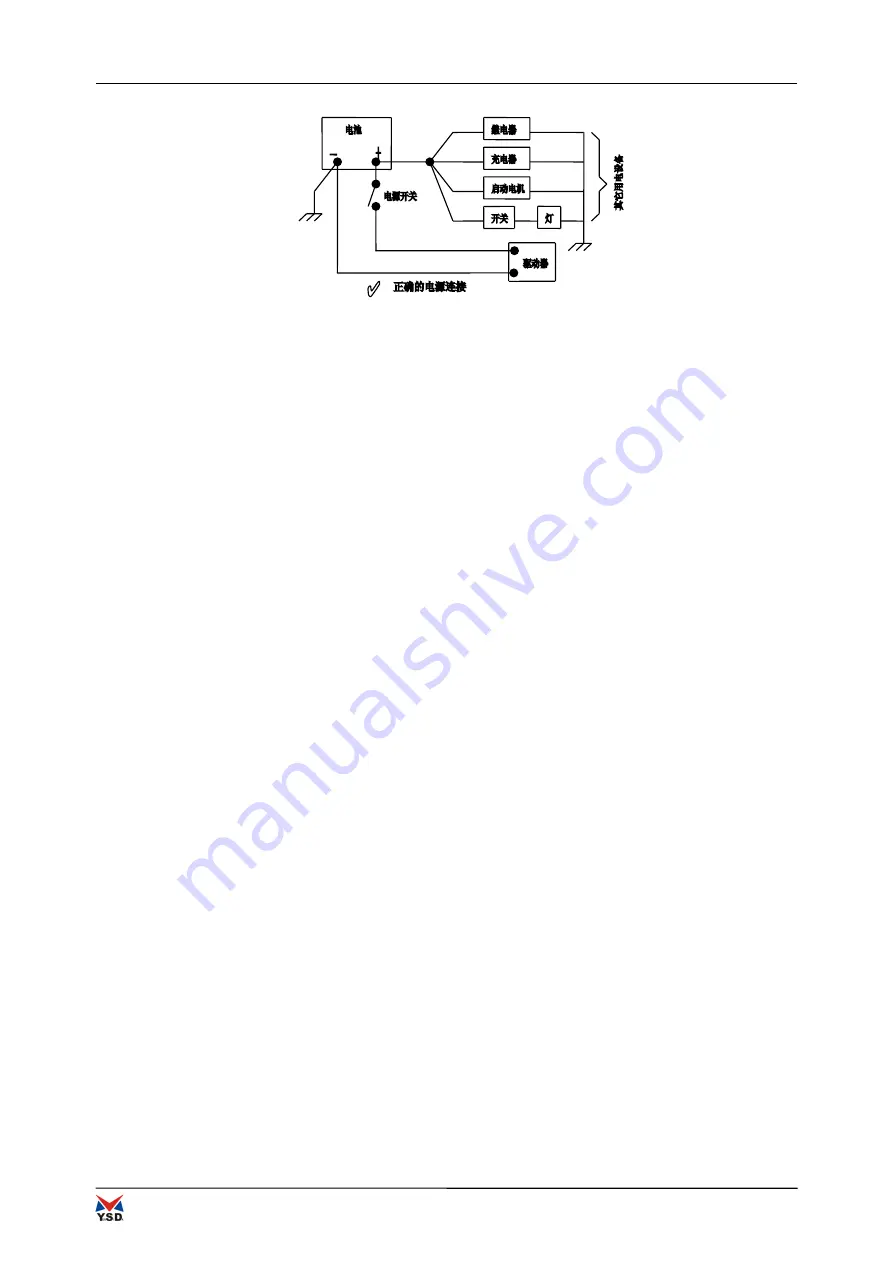

Figure 3-1 power line connection method

4.2 Drive installation

The temperature range of the drive is 40 DEG C 70. The driver is installed in a position that

is easy to adjust and connection, and should be installed as close as possible to the actuator

and the power supply battery so as to meet the requirement of the cable length. Do not expose

the drive to radiation heat sources such as exhaust pipes or turbocharger.

The driver will generate some heat, so the surface should be in full contact with the air

environment. The driver is fixed on the heat conductive plate with a thickness of no less than

3 and a minimum area of 0.4.

General drive can be directly installed in the control cabinet. Do not install the drive

directly on the engine. Drive installation position should be far away from high voltage or

strong current device and the device that produces electromagnetic interference. After the

initial adjustment is completed, the engine is in normal operation state, and the manual

operation is not needed.

4.3 Actuator installation

The actuator is mounted on the engine, and the actuator itself generates heat,

especially in the case of blocking or other requirements for maximum torque output.

Therefore, the maximum operating temperature of the actuator should not exceed

100.

The installation personnel should consider the thermal conductivity of the installation and

the installation position of the engine body temperature, if the installation position of the

engine body temperature is too high, should take appropriate measures to heat insulation. Under

the general conditions, the high thermal conductivity of aluminum and low carbon steel

materials should be used as a mounting bracket. Air free flow through the upper end of the

heat sink will be conducive to heat. Therefore, the heat sink should be kept clean so as to

improve the heat transfer. Do not spray paint or other materials on the heat sink, as this

will reduce the efficiency of heat transfer.