-10

-

■EPDT-292■

8. Maintenance

Most of product failure is due to foreign substance inside piping. Be careful for foreign

substance inside piping fully. Note that the customer will be required to pay repair charge for

any defect that occurs due to foreign matter. Please understand.

8.1 Warning and caution for maintenance and inspection

Warning

1. When performing periodic inspection or part replacement, be sure to confirm that pressure inside

the product and pipes is equivalent to atmospheric pressure. Cool down the body of the product

until it can be touched by bare hands. Inspection/replacement should be done by skilled experts

(staff of facility management/engineering companies, etc.).

* Failure to follow this notice may result in injury by residual pressure in the product or pipes. If the

temperature is high, it may result in scalds.

2. If leakage from the joint between the body and cover is observed, replace the gasket with a new

one, without re-tightening hex bolts.

* Re-tightening of hex bolt may damage the gasket, causing steam blowout and scalds.

Caution

1. Perform periodic inspection to maintain functions and performance of the product.

* General users should ask experts (staff of facility management/engineering companies, etc.) to

perform periodic inspection.

2. After leaving the product not operated for a long period, perform periodic inspection before start-up

of operation. After periodic inspection, start operation again according to “7. Operation procedure.”

* Failure to follow this notice may cause malfunction due to rust generated inside the product or

pipes.

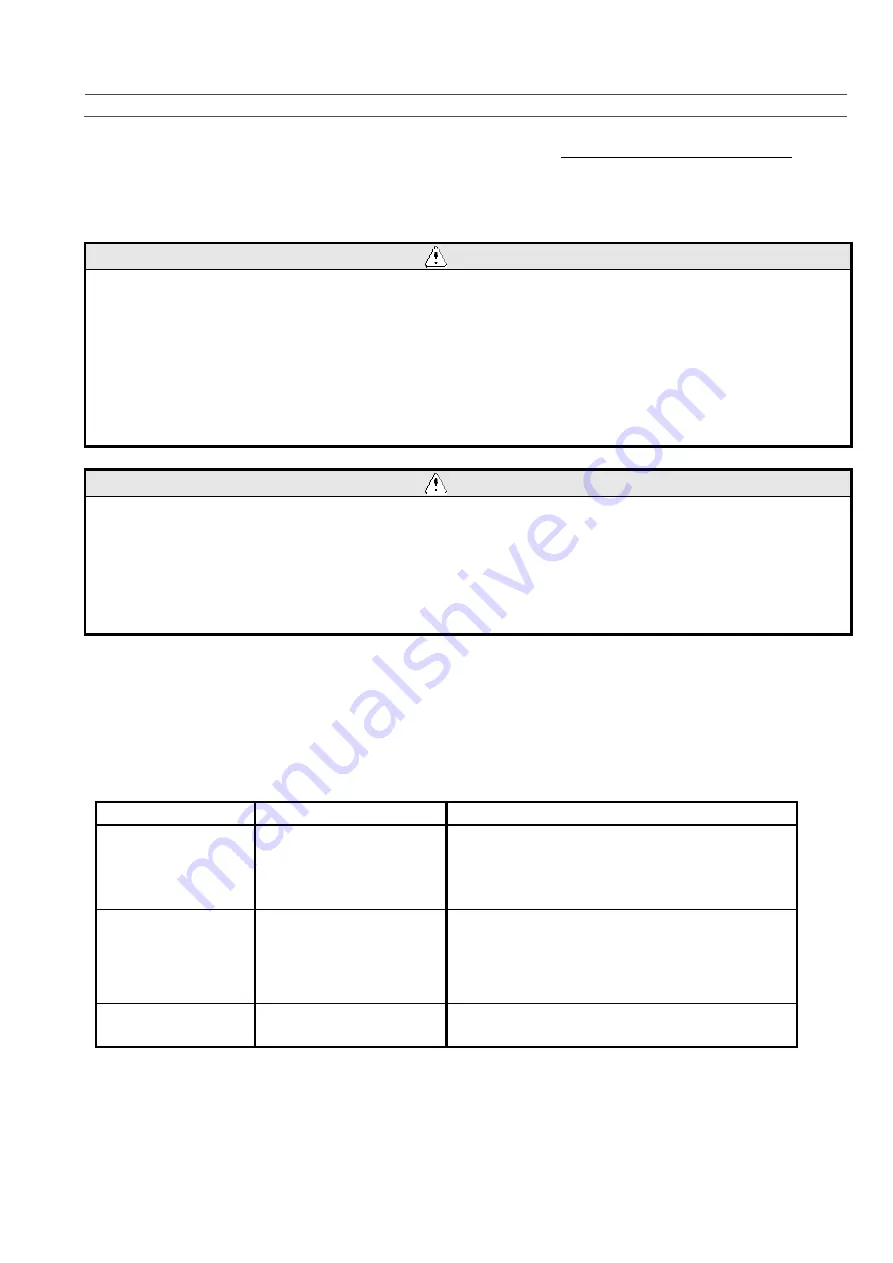

8.2 Daily and Periodic inspection/Periodic replacement

Perform daily and periodic inspection, periodic replacement to maintain functions and

performance of the product.

8.2.1 Daily inspection

Inspect the following items once a day.

(See 6.1. Piping example.)

Items

How to inspect

Remedy

Driving pressure

Confirm that it is

predetermined

pressure using

pressure gauge G1.

Control driving pressure by adjusting

pressure reducing valve 6.

Condensate

discharge

condition

Perform visual check

by sight glass 11.

If condensate is not discharged, see

“8.3 Troubleshooting”.

Outside leakage

Confirm by visual

check.

See “8.3 Troubleshooting”.