JOHNSON CONTROLS

16

FORM 160.69-NM4

ISSUE DATE: 9/30/2020

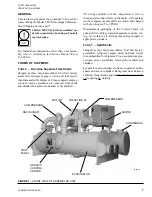

RE-ASSEMBLY

The following is a step-by-step procedure to be used to

assemble the chiller. Refer to

Installation Instruction

(Form 160.69-N3)

for other instructions.

Form 7 Shipment

1. Locate the evaporator and condenser shells in

their final position.

(See

2. Bolt the tube sheets together as shown in

Note that the outside surfaces of

the tube sheets must be flush.

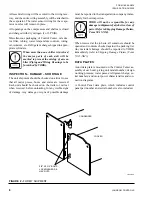

FORM 3 AND FORM 7 SHIPMENT

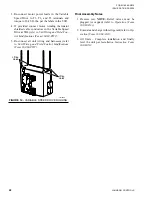

1. Level the shells in both directions. The longitudi-

nal alignment of the shell should be checked by

placing a level on the top of the shell, next to the

discharge connection. The transverse alignment

should be checked by placing a level on the tops

of both end sheets. Refer to

Installation Instruc-

tion (Form 160.69-N3)

for additional instructions

to level the unit. After the shell is leveled, wedge

and shim each corner of the shell to solidly sup-

port it while assembling the other parts.

2. Discharge lines and suction lines should be sten-

ciled as "Drive #1" or "Drive #2". Correct orienta-

tion is necessary for proper fit.

3. Install discharge nozzle onto condenser heat ex-

changer connection using the proper gaskets and

hardware. Verify that the discharge pipe is level in

both directions. Install discharge isolation valve

n top of discharge pipe using proper gaskets and

hardware. Please note that the actuator valve uti-

lizes o-rings instad of a flat gasket. If utilizing any

oil on the o-ring, it's recommended that you use

York "K" oil. See discharge line weight in

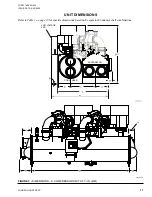

4. Lift a compressor/motor assembly and remove the

packing materials (refer to

for rigging). Carefully lower the compressor/mo-

tor assembly on to the supports on the condenser

discharge valve. Fasten with the proper hardware.

Do not tighten the bolts until all connections are

made to the compressor.

5. Install suction line nozzle onto evaporator heat

exchanger connection using the proper gaskets

and hardware. See discharge line weight in

8 - Suction/Discharge Piping on page 18

.

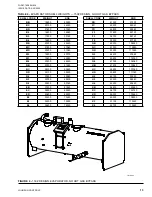

TABLE 6 -

COMPESSOR WEIGHTS

COMPRESSOR

ASSEMBLY

WEIGHT

LBS.

WEIGHT

KGS

K1

364-53357-201

4100

9020

K2

364-53362-201

4200

9240

K3

364-53348-201

6100

13420

K4

364-53349-201

6400

14080

K7

364-53350-201

8100

17820

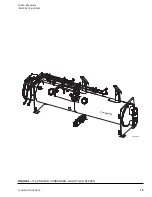

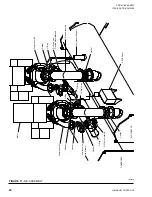

FIGURE 6 -

RIGGING – DRIVELINE ASSEMBLY

LD19863a