FORM 201.24-EG1

47

YORK INTERNATIONAL

YORK Model YCWS ______ Packaged Chiller(s). The

(each) unit shall have a cooling capacity of ______ tons

with Compressor kW when cooling GPM of water from

______ °F (°C) to ______ °F (°C) and with ____ GPM of

condensing water entering at ____ °F (°C) and leaving

at _____ °F (°C), and a cooler fouling factor of _____

and condenser water fouling factor of _____. The water

pressure drop shall not exceed ______ feet (kPa) of

water through the cooler and ______ feet (kPa) of water

through the condenser. The unit overall dimensions shall

not exceed _____feet (mm) _____ ins. in length, ______

feet (mm) _____ ins. in width and _____feet (mm) _____

in height. The unit operating weight shall not exceed

_____ lbs. (Kg).

GENERAL

The (Each) Packaged Water Cooled Screw Chiller shall

be completely factory assembled (in an ISO 9001 regis-

tered facility) including all interconnecting refrigerant pip-

ing and internal wiring of controls, mounted on a steel

base which accommodates the condenser,

compressor(s) and evaporator. Operating test shall in-

clude operation with water flowing through the evapora-

tor.

Unit shall be painted with Caribbean Blue enamel. The

unit shall be shipped with a full operating charge of R-

22. The unit shall contain two separate refrigerant cir-

cuits, each with a single compressor for standby opera-

tion. All units shall be designed and constructed in ac-

cordance with the applicable sections of the following:

American Society of Heating, Refrigeration and Air Con-

ditioning Engineers ANSI/ASHRAE 15 Safety Code for

Mechanical Refrigeration: American Society of Mechani-

cal Engineers ASME Pressure Vessel Code; National

Electrical Code/National Fire Protection Association

NFPA 70. The unit shall be produced at an ISO 9001

registered facility. All chillers are rated in accordance

with ARI Standard 550/590.

COMPRESSORS

Compressors shall be direct drive, semi-hermetic, ro-

tary twin-screw type, including: internal muffler, tempera-

ture actuated ‚off-cycle heater, terminal box, internal dis-

charge check, discharge and suction shutoff service

valves, and precision machined cast iron housing. De-

sign working pressure of entire compressor, suction to

discharge, shall be 31 bar (450psig).

Motors shall feature refrigerant suction-gas cooled two-

pole accessible hermetic compressor motor, full suction

gas flow through a mesh screen, with inherent internal

thermal overload protection and external current over-

load on all three phases. Motor stator shall employ

APT2000 type magnet wire.

Lubrication shall feature external oil separators with no

moving or fragile parts, 31 bar (450psig) design working

pressure, and UL listing. Refrigerant system differential

pressure shall provide oil flow through service replace-

able, 0.5 micron, full flow, cartridge type oil filter internal

to compressor. Filter bypass, less restrictive media, or

oil pump not acceptable.

Compressors shall start at minimum load position. Ca-

pacity control range from 100% to 10% of chiller full load

using continuous function slide valves, and without hot

gas bypass. Step unloading unacceptable. Provide Mi-

croprocessor controlled, output pressure regulating ca-

pacity control valve to command compressor capacity

independent of control valve input pressure and balance

compressor capacity with cooling load.

CAPACITY CONTROL SYSTEM

Continuous function, microprocessor controlled, 3- way

proportional Capacity Control Valve provides regulated

output pressure independent of valve input pressure for

a stable, smooth, and precise match of compressor ca-

pacity to cooling load to 10% of chiller capacity.

COOLER

The cooler shall be a direct expansion shell and tube

type with refrigerant in the tubes and liquid to be chilled

in the shell. The design working pressure of the cooler

shell (liquid) side shall be 150 PSIG for the tube (refrig-

erant) side. Refrigerant heads shall be removable. The

cooler shall be covered with 3/4" flexible closed cell foam

insulation (K = 0.25 maximum) to prevent sweating. The

cooler shall be constructed and tested in accordance

with ASME Code requirements. Vent and drain connec-

tions shall be included. The water connections shall be

fully accessible and grooved to accept victaulic couplings

if used (by others).

CONDENSER

The condenser is a cleanable thru-tube with steel shell,

copper tubes, removable water heads and includes in-

tegral subcooling. Refer to PHYSICAL DATA for design

working pressures. The shell will be constructed and

tested in accordance with section VlII, division 1 of ASME

pressure-vessel code. The condenser is equipped with

relief valves and will hold the full refrigerant charge for

pumpdown.

REFRIGERANT CIRCUITS

Two independent refrigerant circuits will be furnished on

Guide Specifications

Содержание STYLE A YCWS

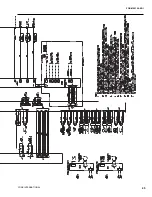

Страница 44: ...44 YORK INTERNATIONAL Typical Control Panel Wiring...

Страница 45: ...FORM 201 24 EG1 45 YORK INTERNATIONAL...

Страница 49: ...FORM 201 24 EG1 49 YORK INTERNATIONAL...

Страница 50: ...50 YORK INTERNATIONAL...

Страница 51: ...FORM 201 24 EG1 51 YORK INTERNATIONAL...

Страница 52: ...Form 201 24 EG1 701 New Release RPC 3M 701 4 16 Codes DXS ET...