5132210-UIM-H-0916

14

Johnson Controls Unitary Products

SECTION VI: OPERATION

The unit is controlled by a conventional heating/cooling thermostat. If an

electronic thermostat is used, make sure it has a common connection.

DO NOT use a power stealing thermostat.

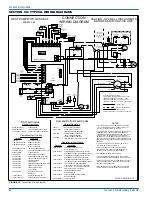

COOLING SEQUENCE OF OPERATIONS

When the thermostat calls for COOL, the thermostat terminals G and Y

are energized, which signals the compressor, outdoor fan and indoor

blower to run.

With a call for Y, the circulating fan is energized at cooling speed.

When the thermostat is satisfied, terminals G and Y are de-energized,

de-energizing the compressor and outdoor fan.

After a cool fan off delay timing of 30 seconds, the circulating fan is de-

energized.

Safety Controls

The control circuit includes the following safety controls:

High Pressure Switch (HP) - This switch protects against excessive dis-

charge pressures due to a blocked condenser coil or a condenser

motor failure (opens at 650 ± 25 psig and closes at 450 ± 25 psig).

The above pressure switches are specifically designed to operate with

R-410A systems. R-22 pressure switches must not be used as replace-

ments for the R-410A pressure switches.

Circulating Fan

When the thermostat calls for FAN, the thermostat terminal G is ener-

gized signaling the circulating fan to run at the G-Speed airflow.

If a call for COOL occurs (Y), the circulating fan switches to run at the Y-

Speed airflow.

If a call for HEAT occurs (W), the circulating fan switches to W-Speed

after a 30 second delay.

When the thermostat ends the call for FAN, the thermostat terminal G is

de-energized, de-energizing the circulating fan.

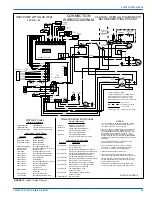

HEATING SEQUENCE OF OPERATIONS

This dual fuel package unit has two stages of heat. Primary heating is

accomplished by the heat pump section. Secondary heating, supple-

mental heating and back up heating is accomplished by the gas heating

section. The gas heating section is also used to temper the indoor dis-

charge air during heat pump defrost operation. The system is not

designed to run heat pump heating and gas heating at the same time.

However, the unit functions this way if the incorrect indoor thermostat is

used or if the incorrect indoor thermostat settings are selected. If the

heat pump and gas heating sections are run at the same time, HI LIMIT

trips may occur. A “Y” call without an “O” call from the indoor thermostat

is primary (heat pump) heat. A “W” call from the indoor thermostat is

secondary or emergency (gas) heat. The indoor thermostat MUST lock

out the heat pump section on a call for supplemental heat or emergency

heat.

Table 14:

Additional Static Resistance

Size (Tons)

CFM

Wet Indoor Coil

Economizer

1

1. The pressure drop through the economizer is greater for 100% outdoor air

than for 100% return air. If the resistance of the return air duct is less than

0.25 IWG, the unit will deliver less CFM during full economizer operation.

2. Filter pressure drop based on standard filter media tested at velocities not

to exceed 300 ft/min.

Filter/Frame Kit

24 (2.0)

500

0.01

0.00

0.01

600

0.01

0.00

0.02

700

0.01

0.00

0.04

800

0.02

0.01

0.06

900

0.03

0.01

0.08

1000

0.04

0.01

0.10

1100

0.05

0.01

0.13

1200

0.06

0.02

0.16

30 (2.5)

700

0.01

0.00

0.04

800

0.02

0.01

0.06

900

0.03

0.01

0.08

1000

0.04

0.01

0.10

1100

0.05

0.01

0.13

1200

0.06

0.02

0.16

1300

0.07

0.03

0.17

36 (3.0)

700

0.01

0.00

0.04

800

0.02

0.01

0.06

900

0.03

0.01

0.08

1000

0.04

0.01

0.10

1100

0.05

0.01

0.13

1200

0.06

0.02

0.16

1300

0.07

0.03

0.17

1400

0.08

0.04

0.18

42 (3.5)

1100

0.02

0.02

0.04

1200

0.03

0.02

0.04

1300

0.04

0.02

0.05

1400

0.05

0.03

0.05

1500

0.06

0.04

0.06

1600

0.07

0.04

0.07

1700

0.07

0.04

0.08

1800

0.08

0.04

0.09

1900

0.09

0.05

0.10

2000

0.09

0.05

0.11

48 (4.0)

1100

0.02

0.02

0.04

1200

0.03

0.02

0.04

1300

0.04

0.02

0.05

1400

0.05

0.03

0.05

1500

0.06

0.04

0.06

1600

0.07

0.04

0.07

1700

0.07

0.04

0.08

1800

0.08

0.04

0.09

1900

0.09

0.05

0.10

2000

0.09

0.05

0.11

60 (5.0)

1100

0.02

0.02

0.04

1200

0.03

0.02

0.04

1300

0.04

0.02

0.05

1400

0.05

0.03

0.05

1500

0.06

0.04

0.06

1600

0.07

0.04

0.07

1700

0.07

0.04

0.08

1800

0.08

0.04

0.09

1900

0.09

0.05

0.10

2000

0.09

0.05

0.11

NOTICE

This unit REQUIRES the use of a thermostat to control fossil fuel

(dual fuel) operation.

WARNING

The ability to properly perform maintenance on this equipment

requires certain expertise, mechanical skills, tools and equipment. If

you do not possess these, do not attempt to perform any mainte-

nance other than those procedures recommended in this Installation

Manual. Failure to heed this warning could result in serious injury

and possible damage to this equipment.

!