YORK INTERNATIONAL

122

FORM 100.50-NOM1 (604)

Service

in man u al). The duct pressure transducer mea sures dif-

fer en tial pres sure between the pressure in the duct and

at mo spher ic pressure. When verifying trans duc er op er a-

tion, the tech ni cian must insert a tee into the pneumatic

tubing to con nect a manometer and ver i fy the pressure

being applied to the transducer. Once this pressure is

known, a com par i son can be made of the duct pressure

vs. output volts DC from the transducer. Table 23 shows

the relationship between the pressure applied to the duct

pressure trans duc er and the output voltage.

Building Pressure Transducer

The building pressure transducer is located in the re turn

air section of the unit. The purpose of this trans duc er is

to sense and convert the static pressure in the building

to a DC voltage. The DC voltage is then sent to the unit

controller and compare against the

Building

Pressure

setpoint

. The control wiring from the trans duc er is fac-

tory wired, but pneumatic tubing must be

Þ

eld supplied

and installed (refer to Installation section in manual).

The building pressure transducer measures differential

pressure between the pressure in the build ing and at-

mospheric pressure. When verifying trans duc er opera-

tion, the technician can insert a tee into the pneumatic

tubing to connect a manometer and verify the pressure

being applied to the transducer. Once this pressure is

known, a comparison can be made of the duct pressure

vs. output volts DC from the transducer. A practical and

quick check of this transducer can also be accomplished

by removing the pneumatic tubing lines from both high

and low side connections on the trans duc er. Since both

of the inputs will now be exposed to the same pressure,

the differential pressure will be zero, and output 2.5

VDC according to the Table 24.

ANALOG INPUT OPERATION

This section describes the control operation of the (13)

thirteen analog inputs. These inputs will be used by the

control to monitor and respond to unit temperatures,

pressures, enthalpy, etc. The connection “layout” for

the IO (inputs/outputs) is shown in the Primary Unit

Controller connection map in Figure 21. Notice that the

Þ

gure shows the Jack connection designated by “J”, and

the pin num ber located on the inside of the board dia-

gram. The input or output designations are shown on the

out side of the

Þ

gure. For example, J11 – 8 is jack eleven

- pin 8 and is AI5 (analog input 5). J13 – 6 is jack 13

- pin 6 and is AI14 (analog input 14). For example, AI5

(J11 – 8) is the input for Outside Air Relative Humidity,

and is used as part of the economizer control scheme.

AI13 (J13 – 8) is the input for Supply Air Temperature,

and is used for control in both the CV and VAV control

schemes. The analog inputs are also in the I/O tables in

Table 33 with descriptions for each input.

Return, Outside, Supply Air and Slab

Temperature

The temperature sensors are RTD sensors that can be

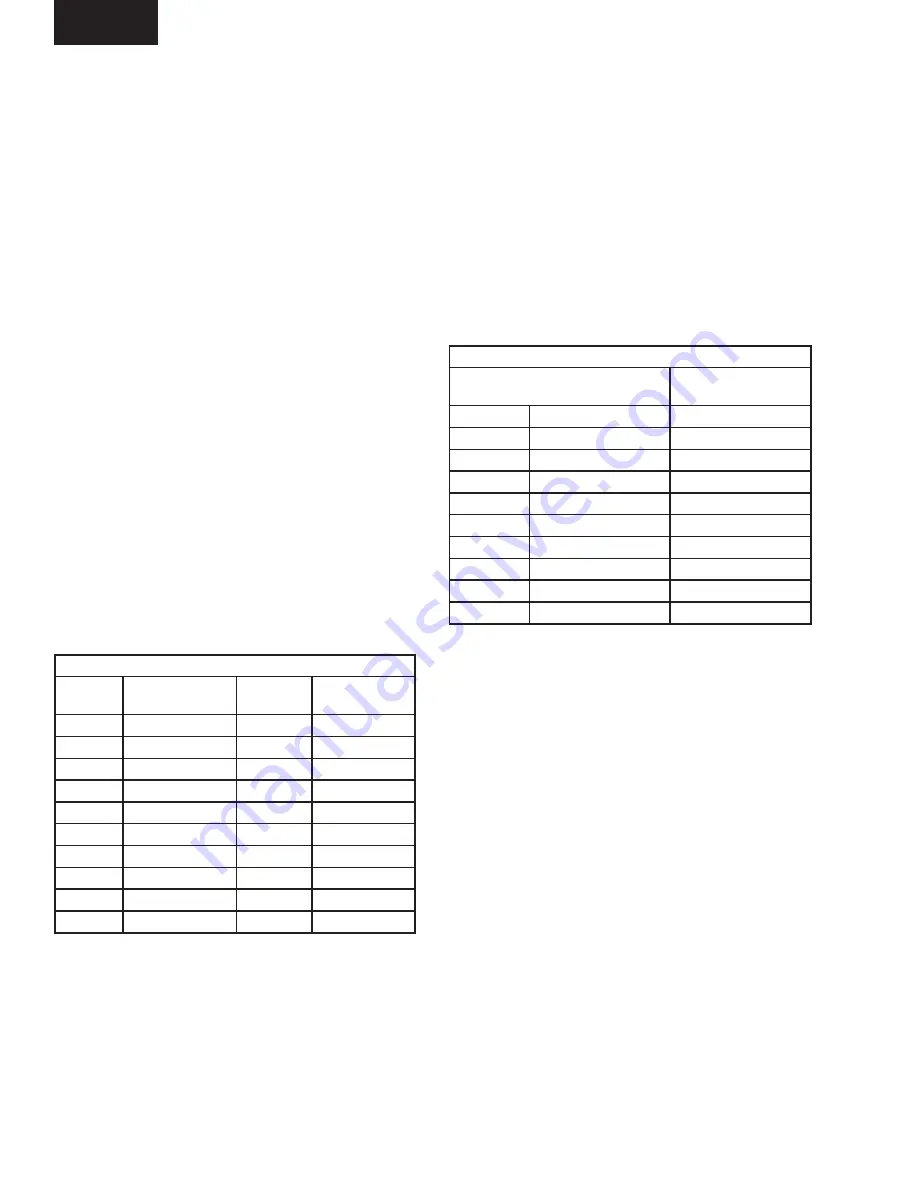

checked with an ohmmeter. Table 22 provides the re sis -

tance values for a given temperature in °F.

Duct Pressure Transducer

The duct pressure transducer is mounted in the return

air section of the unit on the panel wall. The purpose of

this transducer is to sense and convert the static pres sure

in the supply-side of the duct to a DC voltage. The DC

volt age is then sent to the unit controller and com pare

against the

Duct Static Pressure setpoint

. The control

wiring is factory wired, but pneumatic tubing must be

Þ

eld sup plied and installed (refer to Installation section

* 2.5 IWC Duct Transducer Available for FlexSys Option

TABLE 23 – *DUCT PRESSURE TRANSDUCER

OUTPUT TABLE

TEMPERATURE SENSOR OUTPUT TABLE

TEMP.

°F

OHMS

RESISTANCE

TEMP.

°F

OHMS

RESISTANCE

-20

751

80

1030

-10

777

90

1060

0

803

100

1090

10

830

110

1121

20

858

120

1152

30

885

130

1184

40

914

140

1216

50

942

150

1248

60

971

160

1281

70

1000

170

1314

TABLE 22 – TEMPERATURE SENSOR

RESISTANCE TABLE

DUCT PRESSURE TRANSDUCER OUTPUT TABLE

DIFFERENTIAL INPUT

PRESSURE - IWG

OUTPUT VOLTAGE

- VDC

0.5

0.25

0.5

1.0

0.50

1.0

1.5

0.75

1.5

2.0

1.00

2.0

2.5

1.25

2.5

3.0

1.50

3.0

3.5

1.75

3.5

4.0

2.00

4.0

4.5

2.25

4.5

5.0

2.50

5.0