1

Safety Guidelines

To use this product, the following basic measures should be strictly followed to

avoid hazards of electric shock, bodily injury, and fire.

1. To ensure personal safety, please turn off the power switch after power

work is completed; if it will not be used for a long time, please unplug the

power cord! !!

2. Failure to use parts approved or recommended by the manufacturer may have

serious consequences.

3. Power failure must be fixed by professionals or by maintenance personnel

designated by our company.

4. This product uses a three-wire grounded plug that must be inserted into a

three-hole grounded outlet. Do not change the plug or use an ungrounded

three-headed adapter as it will cause poor grounding.

5. After the soldering station is switched on, its temperature can exceed 400

degrees centigrade. Do not use near flammable or explosive objects. To avoid

burns, do not touch the metal part of the soldering iron.

6. Do not leave the work area when the soldering station is switched on.

7. The power cord must be unplugged and the iron must be allowed to cool before

installing or replacing soldering iron parts.

8. The soldering iron should only be used for soldering. Do not hit the soldering

iron against the work surface to remove flux residues, as doing so may

seriously damage the soldering iron.

9. Soldering produces fumes, ensure there is adequate ventilation.

WARNING

1. If the power cable is damaged, it must be replaced by the manufacturer or by a

maintenance department professional in order to avoid danger.

2. This tool must be placed in its stand when not in use.

3. Be careful when using this device in the vicinity of flammable materials; Never

use this device for extended periods in the same location.

4. Be aware that heat may be transferred to distant flammable materials;

Someone must be present at all times while the device is connected.

5. This device is not intended to by operated by individuals with diminished

physical, sensory, or mental capacities or by those who lack experience (such

as children), except in the presence of individuals qualified to provide

necessary supervision and guidance; Ensure that children do not play with this

device.

2

1. Uses touch screen technology, stylish and convenient to use

2. Features 3 working channels, allowing storage at different temperature and air

flow parameters; parameters can be quickly selected based on the IC type

3. Features Fahrenheit/Celsius display switch and digital calibration.

4. Closed loop sensor, no-touch temperature control by microcomputer, high

output, rapid heating; temperature regulation is convenient and precise.

5. Uses brushless vortex blower with large airflow, adjustable.

6. System features automatic cold air function, prolonging the life of the heating

element and protecting the handle.

I. Product Features

1. Suitable for soldering of many types of original parts, including SOIC, CHIP,

QFP, PLCC, and BGA.

2. Suitable for heat shrinkage, drying, paint removal, adhesive removal, thawing,

preheating, disinfection, and plastic welding.

3. Suitable for heating using different levels of airflow and heat.

4. Suitable for lead free hot air reworking.

II. Usages

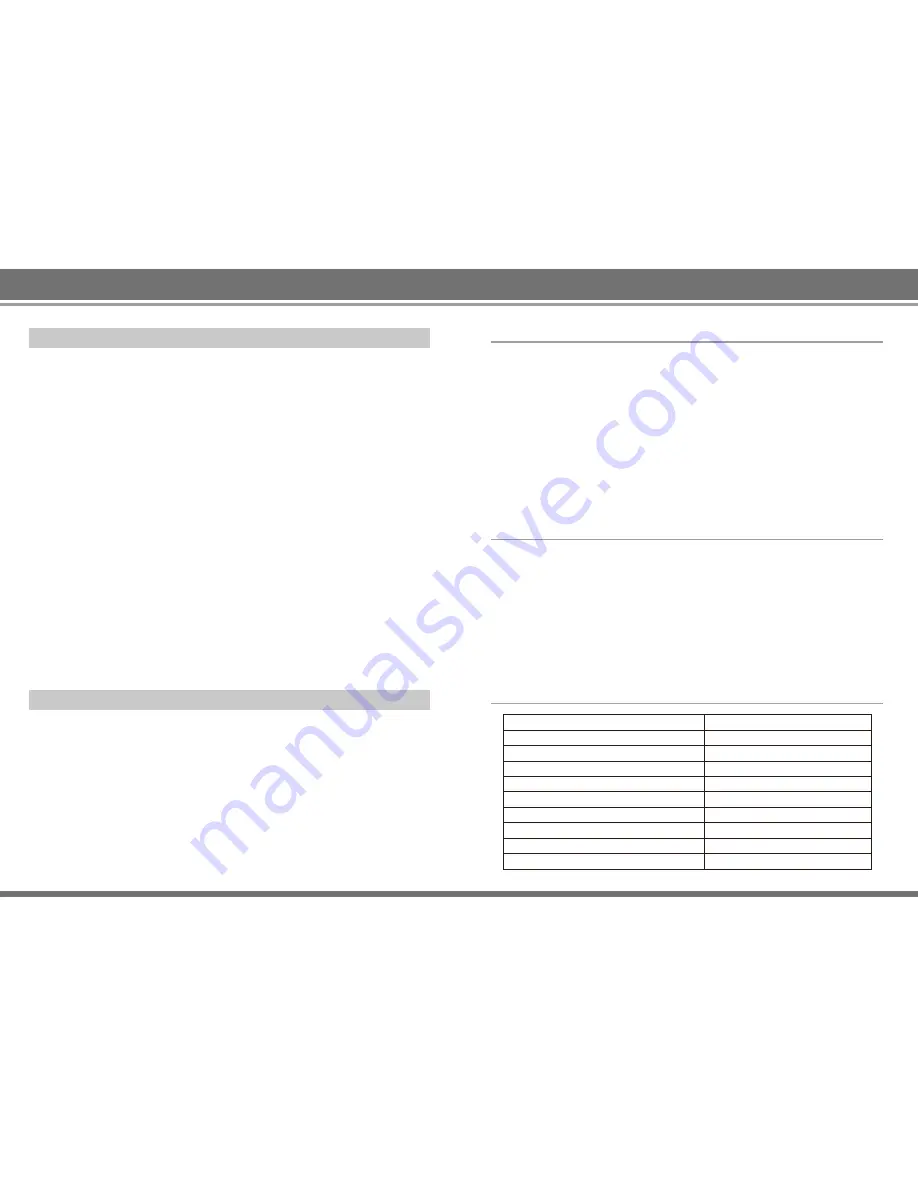

III. Parameters

Power

Voltage range

Temperature range

Air volume stalls range

Maximum air flow

Dimensions (length x height x width)

Weight (including handle bracket)

Working environment

Storage environment

Storage Humidity

1300W

200V~240V 50Hz ~ 60Hz

100°C to 500°C

6 ~ 200

200L / min

230x205x170mm

about 4.5kg

0~40°C / 32~104°F

-20~80°C / -4~176°F

35% to 45%