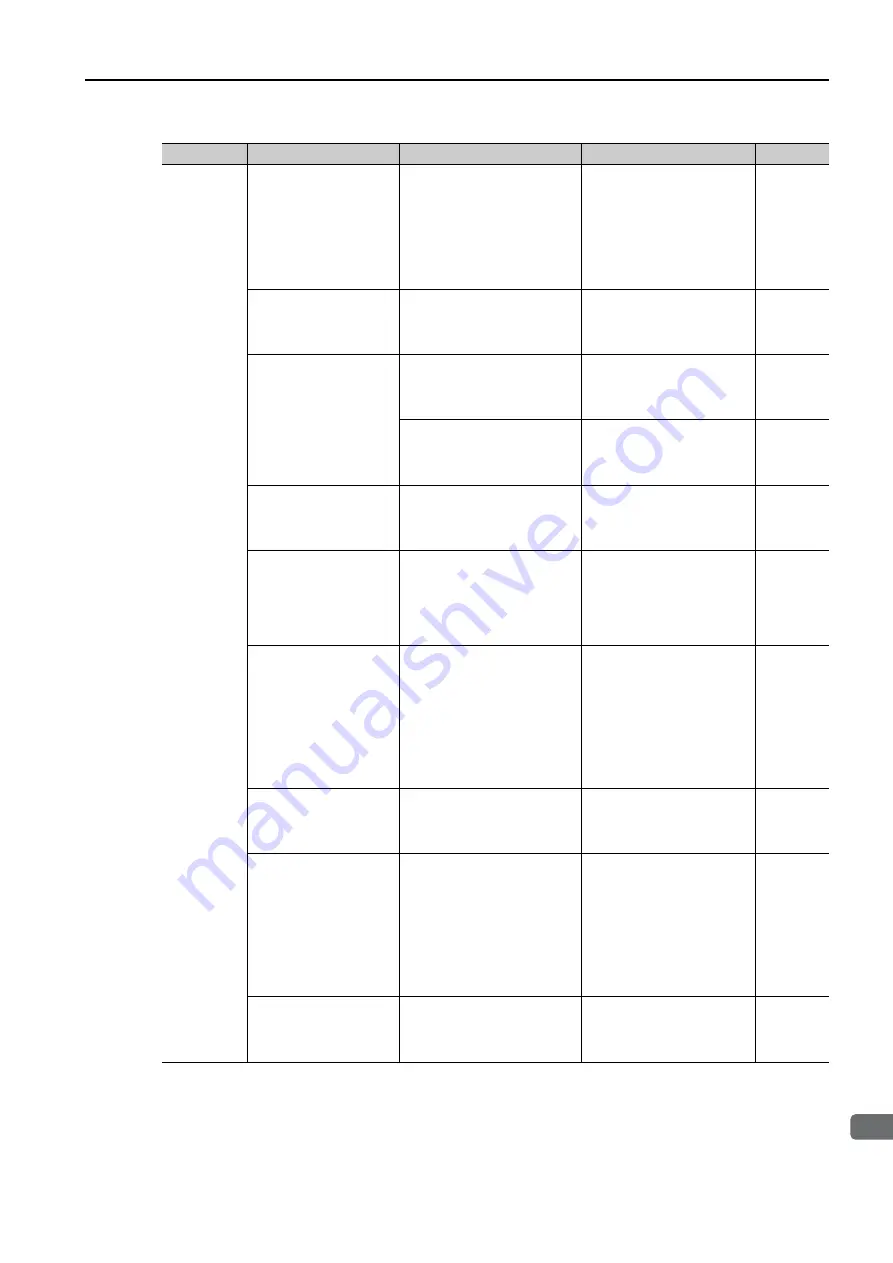

5.7 Troubleshooting Based on the Operation and Conditions of the Servomotor

5

Maintenance

5-45

Abnormal

Noise from

Servomotor

The Servomotor

vibrated considerably

while performing the

tuning-less function

with the default set-

tings.

Check the waveform of the

motor speed.

Reduce the load so that

the moment of inertia ratio

or mass ratio is within the

allowable value, or

increase the load level or

reduce the rigidity level in

the tuning-less level set-

tings.

*

The machine mounting

is not secure.

Turn OFF the power supply

to the servo system.

Check to see if there are any

loose mounting screws.

Tighten the mounting

screws.

–

The machine mounting

is not secure.

Turn OFF the power supply

to the servo system.

Check to see if there is mis-

alignment in the coupling.

Align the coupling.

–

Turn OFF the power supply

to the servo system.

Check to see if the coupling

is balanced.

Balance the coupling.

–

The bearings are

defective.

Turn OFF the power supply

to the servo system.

Check for noise and vibra-

tion around the bearings.

Replace the Servomotor.

–

There is a vibration

source at the driven

machine.

Turn OFF the power supply

to the servo system.

Check for any foreign mat-

ter, damage, or deformation

in the machine’s moving

parts.

Consult with the machine

manufacturer.

–

Noise interference

occurred because of

incorrect I/O signal

cable specifications.

Turn OFF the power supply

to the servo system.

Check the I/O signal cables

to see if they satisfy specifi-

cations. Use shielded

twisted-pair wire cables or

screened twisted-pair

cables with conductors of at

least 0.12 mm

2

.

Use cables that satisfy the

specifications.

–

Noise interference

occurred because an I/

O signal cable is too

long.

Turn OFF the power supply

to the servo system.

Check the lengths of the I/O

signal cables.

The I/O signal cables must

be no longer than 3 m.

–

Noise interference

occurred because of

incorrect Encoder

Cable specifications.

Turn OFF the power supply

to the servo system.

Make sure that the rotary

Encoder Cable satisfies the

specifications. Use a

shielded twisted-pair wire

cable or a screened twisted-

pair cable with a conductors

of at least 0.12 mm

2

.

Use cables that satisfy the

specifications.

–

Noise interference

occurred because the

Encoder Cable is too

long.

Turn OFF the power supply

to the servo system.

Check the length of the

Encoder Cable.

The Encoder Cable length

must be 50 m max.

–

Continued on next page.

Continued from previous page.

Problem

Possible Cause

Confirmation

Correction

Reference