9

Maintenance and Inspection

9.3 Grease Replenishment/Exchange

9-11

173124-1CD

HW1482991

MPL300

II

9.3.3.1 Grease Replenishment

(Refer to

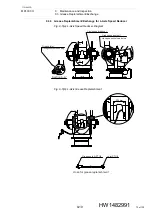

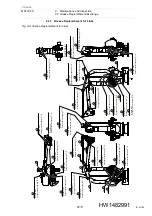

Fig. 9-5(a) “L-Axis Speed Reducer Diagram”

and

Fig. 9-5(b) “L-Axis Grease Replenishment”

.)

1. Remove the hexagon socket head plugs from the grease inlet and

grease exhaust port.

2. Install a grease zerk A-PT1/8 to the grease inlet.

(The grease zerk is delivered with the manipulator.)

3. Inject grease through the grease inlet using a grease gun

– Grease type:

Molywhite RE No.00

– Amount of grease:

360 cc

(720 cc for 1st supply)

– Air supply pressure of grease pump: 0.3 MPa or less

– Grease injection rate:

8 g/s or less

4. If you cannot inject grease with your grease gun, prepare a grease

hose as shown in

and inject grease.

5. Move the L-axis for a few minutes to discharge excess grease.

6. Wipe the discharged grease with a cloth, and reinstall the plug. Before

installing the plug, apply Three Bond 1206C on the thread part of the

plug. Then tighten the plug with a tightening torque of 24.5 N•m (2.5

kgf•m).

7. Remove the grease zerk from the grease inlet, and reinstall the plug.

Before installing the plug, apply Three Bond 1206C on the thread part

of the plug. Then tighten the plug with a tightening torque of 4.9 N•m

(0.5 kgf•m).

NOTE

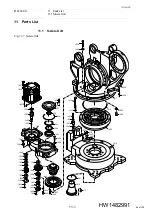

• If grease is injected with the plug on, grease will leak

inside the motor and may cause a damage. Make sure to

remove the plug before the grease injection.

• Do not install a joint, a hose, etc. to the grease exhaust

port. Failure to observe this instruction may result in

damage to the motor due to coming off of an oil seal.

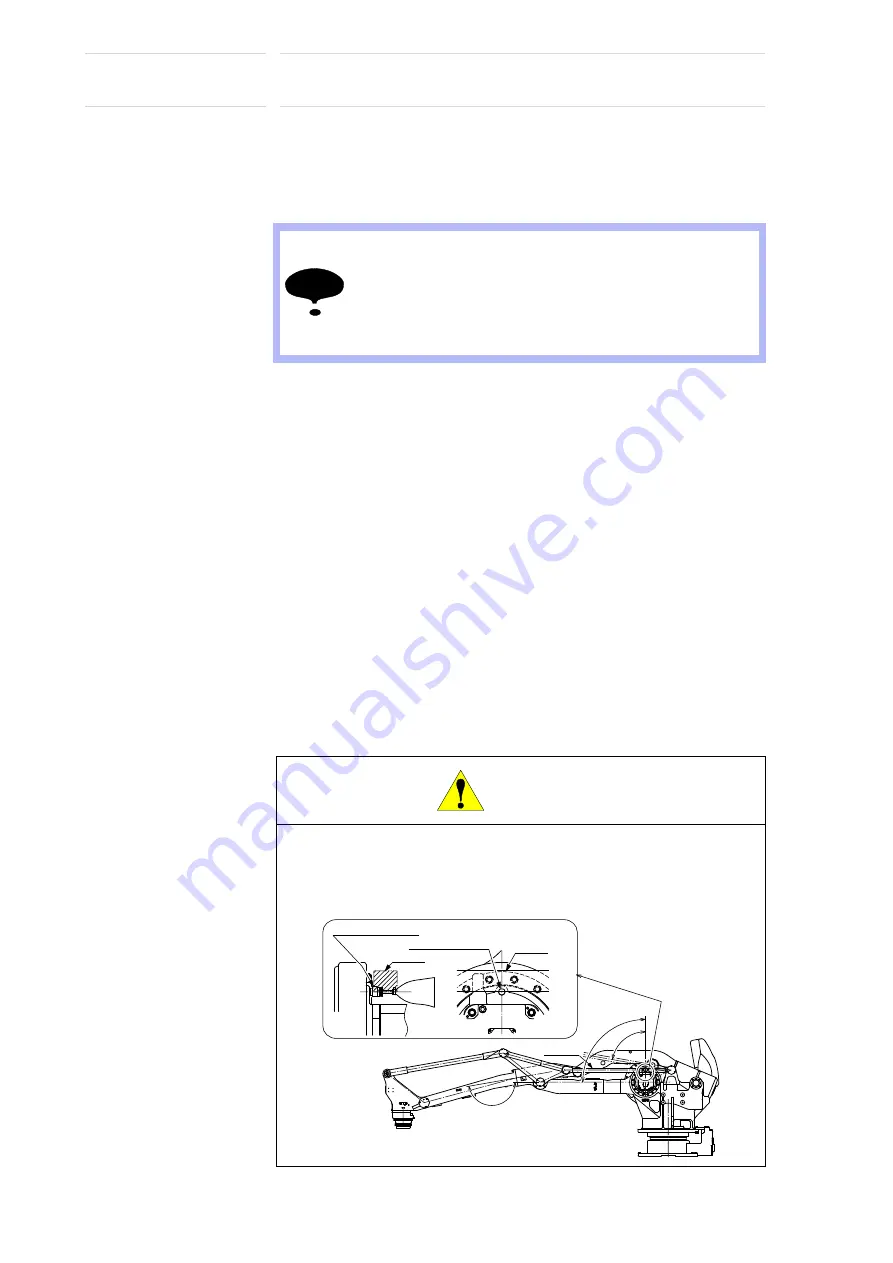

CAUTION

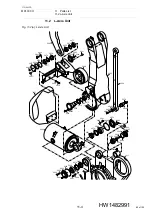

•

If the L-arm is tilted at 80 degrees or more, the link-C interferes with

the plug for air exhaust.

Do not tilt the L-arm over 80 degrees when verifying the manipulator

operation.

Plug for air exhaust

Link-C

Plug for air exhaust

Link-C

Link-C

80°

90°

170°

74 of 100