model number 054-5757-2 | contact us: 1.866.523.5218

20

•

Maintain proper chain tension always. A loose chain will increase the risk of

kickback. A loose chain may jump out of guide bar groove. This may injure operator

and damage chain. A loose chain will cause chain, bar, and sprocket to wear

SBQJEMZ5IFDIBJOMJGFPGUIFTBXDIBJONBJOMZEFQFOETVQPOTVGªDJFOUMVCSJDBUJPO

and correct tensioning. Avoid tensioning the chain if it is hot, as this will cause the

chain to become over tensioned when it cools down.

1MBDFUIFDIBJOTBXPOBOZTVJUBCMF«BUTVSGBDF

2. Turn the Chain Tensioning Knob (11) clockwise until it is hand tight. The tension is

automatically set while the Chain Tensioning knob is being tightened.

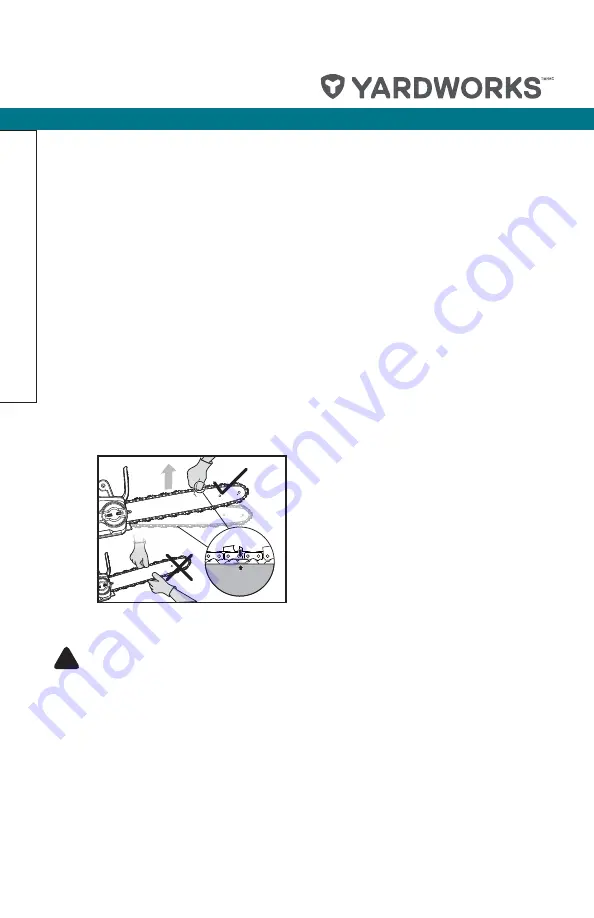

3. Double check the tension set by the automatic Chain Tensioning Knob. The correct chain

tension is reached when the Chain (10) can be raised approximately 0.12

–

0.24” (3

–

6

mm) from the Guider Bar (9) in the centre. This should be done by using one hand to raise

the chain against the weight of the machine. (See Fig. B)

4. The chain will stretch from use and lose proper tension. To retension the chain, turn knob

counter-clockwise (3x), secure the chain cover, and repeat steps 1

–

3 listed above.

LUBRICATION

!

*NQPSUBOU5IFDIBJOTBXJTOPUTVQQMJFEªMMFEXJUIPJM*UJTFTTFOUJBMUPªMMXJUIPJM

before use. Never operate the chainsaw without chain oil or at an empty oil tank level as

this will result in extensive damage to the product. Chain life and cutting capacity

depend on optimum lubrication. Therefore, the chain is automatically oiled during

operation via oil outlet.

FILLING OIL TANK: (See Fig. C1 and C2)

1. Set chainsaw on any suitable surface with Oil Filler Cap (5) facing upward.

2. Clean area around the Oil Filler Cap (5) with cloth and unscrew the cap by turning it

counter-clockwise.

3. Add bar and chain oil SAE30 until reservoir is full.

Bar

0.12-0.24"

(3-6 mm)

B

Assembly