IDLE SPEED

Set the lever to the SlOW position to reduce stress on the engine

when chipping is not being performed. lowering the engine speed

will help extend the life of the engine, as well as conserve fuel and

reduce noise level.

STOP ENGINE

To stop the engine, use the following procedure:

1. Move the lever to stop position.

2. Close fuel shut-off valve.

Make sure the machine is level and stable to avoid

unnecessary vibrations.

Do not operate on concrete or other hard surface.

Do not open the housing cover unless the engine and

cutting disk are completely stopped.

To shut down the machine, move the lever to idle

speed, and it will gradually come to a standstill.

Sudden stopping at a high speed under a heavy load

is not recommended. Engine damage may result.

Wait until the machine completely stops. Allow the engine to

completely cool. Remove the engine’s spark plug. Then clean out

the interior of the machine and its discharge chute.

The chipper can clog up with soft, wet, or fibrous materials.

However, if you feed soft materials intermittently with branches,

there should be no problem, as the chipper tends to clean out any

residue left in the machine.

If any stringy material wraps around the rotor shaft, remove it

before it works its way into the bearing.

If the chipper stalls from overloading or clogging, turn off the

engine’s power switch and wait until the cutting disk is completely

stopped. Allow the engine to completely cool and switch the

engine to off. Open the housing cover to clear and remove all the

materials from the housing. lock the housing cover, switch the

engine to the on position, and start the machine again to resume

operation.

As the discharge material plies up, move the chipper away from

the pile. This will keep the material from backing up the discharge

chute. Do not position the deflector vertically, as this will reduce

the airflow, impeding the discharge and causing blockage.

Feed tree limbs or branches with the cut end first into the hopper

opening, leaving the brushy head to be chipped last. This helps

guide the limb down the feed hopper opening and reduces the

chance of cut pieces being toss back up the hopper opening. Some

branches may be required to be pre-cut to provide the a more

efficient self-feeding action.

It is recommended to process freshly cut materials, as older

branches get dried out and brittle. Older, dryer branches will dull

the cutting knifes quicker than freshly cut ones.

While operating the machine, keep a wooden stick handy,

approximately 1 inch in diameter by 2 feet long. This stick will be

useful to push in short, brushy and very leafy materials and keep

the feed hopper clear.

Do not force material into the machine. If it does not chip well, the

chipper knives may need sharpening or to be replaced.

Do not overload the machine by filling the hopper opening with

too much material at one time. As a load passes through the

cutting disc and is discharged, the engine speed may decrease.

Allow enough time for the engine to accelerate to the highest RPM

before another load is added. In the event of overload condition,

stop feeding material into the hopper.

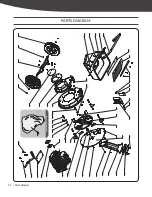

Chipper Cone

Feed Hopper

NO HANDS BELOW THIS LINE

This chipper can process tree limbs, branches, and organic matter

(such as corn stalks). Tree branches must be inserted with the

large, cut end first into the Chipper Cone Opening. As the unit

chips the load, there will be some occasional debris kickback.

Always stand away from the unit and allow the self-feeding action

pull the load to the cutting disc.

The chipper shredder is designed to break down and shred light

brush, leaves, and soft but bulky organic waste. load this type of

material (no larger than ½” in diameter) into the top of the Feed

Hopper. The material is then pulled into the cutting chamber by

air flow.

15

|

Operation

36060US25M100_KOHLER.indd 15

2017/10/17 11:06:12